Encoders,

Interrupts and I/O expansion with Arduino

My approach to reading

front-panel controls, including encoders

The problem

Reading buttons and other

user inputs in the loop() code of an Arduino is generally a bad

idea. Other routines can block this code from executing.

Particularly updating displays which can take many 10's or even

100's of mS. A quick button press can occur in 20-50 mS, and

can be missed.

Mechanical switches, including encoders, generate 'contact

bounce'. Contact bounce occurs when a switch is turned on or off.

It causes multiple, fast pulses for about 1 to 10mS. And it gets

worse as the switch ages, and its contacts wear out and oxidize.

The Arduino libraries for encoders and switches are either polled,

or interrupt based. Either of these is not ideal.

Polling can miss events because of long events in the loop().

Interrupts work better, but the 1-10 mS of contact bounce can

cause many interrupts to occur. And each switch requires a

separate I/O pin with interrupt capability. This is a problem with

5, 10 or more switches. Filtering the encoder with pull-up

resistors and capacitors to GND reduces the contact bounce.

Some warnings

When I worked at

Analogic, we had a product called the AN8200, a precision voltage

source. We referred to it as the VoltBox. It had 6 encoders, and

each controlled one digit on the front panel. These were

old-school Grayhill mechanical encoders. They worked well when

new, but as they got old and the contacts oxidized, the contact

bounce increased, and the switches caused erroneous results. The

engineers who wrote the firmware that reads the encoders didn't

take this into account. The encoders, no longer available,

need to be painfully removed, disassembled, contacts cleaned,

assembled, and reinstalled.

HP generally uses quality components. But their modern instruments

such as the HP 33250A and 33220A waveform generators have

notoriously unreliable encoders. There are a number of Youtubes on

this issue.

Scope of the

discussion: not position encoders

This page relates to

optical and mechanical encoders intended for front-panel controls.

Other encoders used for position control are typically higher

resolution and are optical. These can have much higher resolution

and speed, and should be designed to never miss a pulse. I

recommend using specific hardware readers for these. There are

specific ICs, and there are microprocessors with encoder reading

hardware. Use one of these solutions. Unless the encoders are slow

(< 1KHz), software solutions will cause you headaches.

The solution

Most embedded

applications have some real-time requirements, including any with

buttons or encoders. I use a timed interrupt, generally about 1mS,

to read all of the front panel switches and other critical I/O

requirements. For example, if I need a regular ADC measurement, I

put it in the 1mS interrupt handler. If the event can occur at a

slower rate, a simple counter in the interrupt routine can

generate slower interrupts.

Timed Interrupts

With a timed interrupt,

be careful not to include any lengthy code. Try to avoid while()

loops, or lengthy for() loops. In-line code, including digital and

analog I/O is pretty safe. I generally use a spare digital output

bit to see how much time the interrupt routine takes: set the I/O

bit at the beginning of the interrupt and clear it at the end.

With a 'scope, you can easily see how long the interrupt is

taking.

Another gotcha with interrupts is sharing I/O resources. If loop()

is using an I/O resource (a Pin, ADC, SPI, I2C, etc.), then the

interrupt trying to use the same resource can mess it up big-time

unless some type of semaphore is used to avoid conflicts. It can

get tricky. And you really don't want your interrupt routine to be

waiting a significant time for a slow I/O device in loop(). Be

very careful..... Try to have each resource be either polled in

loop() or using an interrupt, but not both.

In the early days of Arduino, I struggled with timed

interrupts, since each type of processor used a different timer. I

would read the processor data sheet and bang the appropriate

registers. Now there are timed interrupt libraries that are

consistent across platforms. I use https://github.com/khoih-prog/SAMD_TimerInterrupt

for the ItsyBitsy SAMD21. He has others for other processors.

Encoders

Mechanical encoders are

low-cost and convenient ways to control digital stuff on a

front-panel. They are basically switches that operate much faster

than simple push-buttons. Most have two outputs, A and B, that

operate in quadrature. There are many encoder options:

- Quadrature or

absolute

- Mechanical detent

(click) or no click

- 10-20 or more clicks

or pulses per rotation (PPR)

- 1 or 4 transitions

per click

- Mechanical

(switches) or Optical

- Optional push switch

- Various sizes,

shapes, and pinouts

- Various mountings,

shaft lengths, and shaft types.

- Knob size:

- Larger knobs are

easier to control with precision

- Smaller ones can

be controlled faster

A simple Digikey search

for encoders shows about 10,000 part numbers. An

embarrassment of riches. I generally use these ones from TT.

- EN11-HNM1AF15

20PPR, no switch, short 'D' shaft, $2.15

- EN11-HSM1AF15

same, with a push switch, $3.00

Quadrature means that the

2 outputs are 90 degrees out of phase with each other. When you

rotate in one direction, first switch A closes, then A and B, then

B, then both OFF. In the other direction, B is first. By looking

at the phase of A vs B (which comes first), the direction of

rotation can be determined.

Most mechanical ones have a click and are 16 to 24 clicks per

rotation. Most are also 4 transitions per click.

Optical ones may or may not have a click, can have many more

pulses per rotation, and generally don't have contact bounce. With

a lot of pulses, the knob size should also be increased.

How to read an encoder

The standard Arduino

libraries for encoders are either polled or interrupt driven.

Instead, I wrote my own code, using a 1mS timed interrupt:

- Read the A and B

bits every 1mS

- Combine the 2 bits

with the previous reading's 2 bits into a 4 bit value

- Use a look-up-table

(LUT) to output:

- Idle: no change

- Up count

- Down count

Here is the

Look-up-table (encoder_logic) for a TT encoder and the the

Interrupt code.

/* Encoder */

/* For encoders that generate 4 transitions per click such as most mechanical encoders.

Note that mechanical encoders need pull up resistors and should also have R-C filters

*/

const uint8_t encoder_logic[] = {

/*old new action

---------------------- */

/* 00 00 */ NADA,

/* 00 01 */ NADA,

/* 00 10 */ DECR,

/* 00 11 */ NADA,

/* 01 00 */ NADA,

/* 01 01 */ NADA,

/* 01 10 */ NADA,

/* 01 11 */ NADA,

/* 10 00 */ INCR,

/* 10 01 */ NADA,

/* 10 10 */ NADA,

/* 10 11 */ NADA,

/* 11 00 */ NADA,

/* 11 01 */ NADA,

/* 11 10 */ NADA,

/* 11 11 */ NADA

};

/* getEncoder()

This is the interrupt routine for the encoder.

The encoder is an optical encoder knob that outputs A-B quadrature signals. The knob is

rotated relatively slowly, so once every 1 mS the 2 bits are polled. These are compared

to the previous readings and depending on the sequence, either the count value is

incremented, decremented or not action (NADA).

The logic is contained in encoder_logic[] a table.

The encoder state is 4 bits. The 2 LSBs are the new bits. The MSBs [3:2] are the previous readings.

*/

void getEncoder(void)

{

uint8_t action;

static uint8_t encoder_state;

/* read 2 LSBs, shift up the previous bits */

encoder_state = (encoder_state << 2) | (digitalRead(ENCB) << 1) | digitalRead(ENCA);

action = encoder_logic[encoder_state & 0x0F]; /* Look up action: 4 LSBs only */

if (action == INCR)

encoder_count++;

if (action == DECR)

encoder_count--;

}

Reading Keys (buttons)

There are a million ways

to read buttons. Since I'm already using a 1mS interrupt, it is

fairly fast to scan all the buttons, and debounce. And while you

are at it, you can time the key press for key repeat, long press,

etc.

I keep one variable keyState per button to maintain the key state.

keyState = 0 means it is not pressed. Then count every scan that

the button is pressed. If it bounces, reset to 0. After about 10

mS, generate a key valid for that key.

I/O Expansion

When you have a bunch of

buttons and an encoder on a front panel, you can run out of I/O

pretty quickly. The Nano type processors (Nano, Teensy, ItsyBitsy,

Feather, ESP32...) have about 10 or 15 general purpose digital

I/Os other than I2C, SPI and Serial. An encoder with a press

button uses 3 I/Os, and switches use one each. LEDs use one each

also.

I like to read and debounce all the buttons in a timed interrupt.

So reading all the bits should be fast. Here are several ways to

expand I/O

Use a multiplexer

An analog or digital

multiplexer can read several switches and allow fewer bits to

handle them. Analog switches have the advantage that the

processor's pull-up resistor is also multiplexed. Digital muxes

require one pull-up resistor per switch.

Multiplexer

|

#

of switches

|

Output

Bits

|

Input

bits

|

Notes

|

Cost

|

8:1

analog (74HC4051)

8:1 digital (74HC151)

|

8

|

3

|

1

|

Requires

3x8 digital writes.

Output pins can be shared if > 8

Digital requires pull-up per switch

|

$0.30

|

16:1

analog (2x 74HC4051)

|

16

|

4

|

1

|

Requires

4x16 digital writes

|

$0.60

|

Use a crosspoint

(matrix)

An X-Y matrix of

switches can be used. For a large number of switches this is

practical. For 16 switches, this requires 4 output and 4 input

bits, so only a 16 -> 8 pinout savings. If a HW 2:4 decoder

is used, then that saves 2 more output pins, so a 16 -> 6

savings. .

For 8x4 with a 3:8

decoder, 3 output and 4 inputs are needed for a 32 -> 7 pin

savings.

analog or digital

multiplexer can read several switches and allow fewer bits to

handle them. Analog switches have the advantage that the

processor's pull-up resistor is alo multiplexed. Digital muxes

require one pull-up resistor per switch.

In a martix, there is an

artifact called 'shadowing'. This is when 2 buttons are pressed at

the same time, and the processor cannot tell that all 4 of the

keys that share the same rows and columns are not pressed.

And if the outputs are totem-pole (High and low drive) then

pressing multiple buttons can short two or more outputs, causing

high current. Using a diode on each output or using open-collector

(or open-drain) outputs addresses this issue. In Arduino, outputs

can be open-drain, but that requires additional port operations.

For a 4 x 4 matrix with HW decoder, each column requires 2 writes.

Each row requires 4 reads. So 4 * (2 + 4) = 24 operations.

For a 8 x 4 matrix with HW decoder, each column requires 3 writes.

Each row requires 4 reads. So 8 * (3 + 4) = 72 operations.

Since Arduino I/O uses one bit reads and writes, this can be slow.

Using a DigitalReadFast and DigitalWriteFast library will

help. If a bunch of bits are in the same processor I/O port,

low-level register reads would speed it up a whole lot. Maybe

there is a library for this?

Another speedup is to read only one or 2 columns per 1mS

interrupt. 2ms or 4ms poll time for buttons ain't bad.

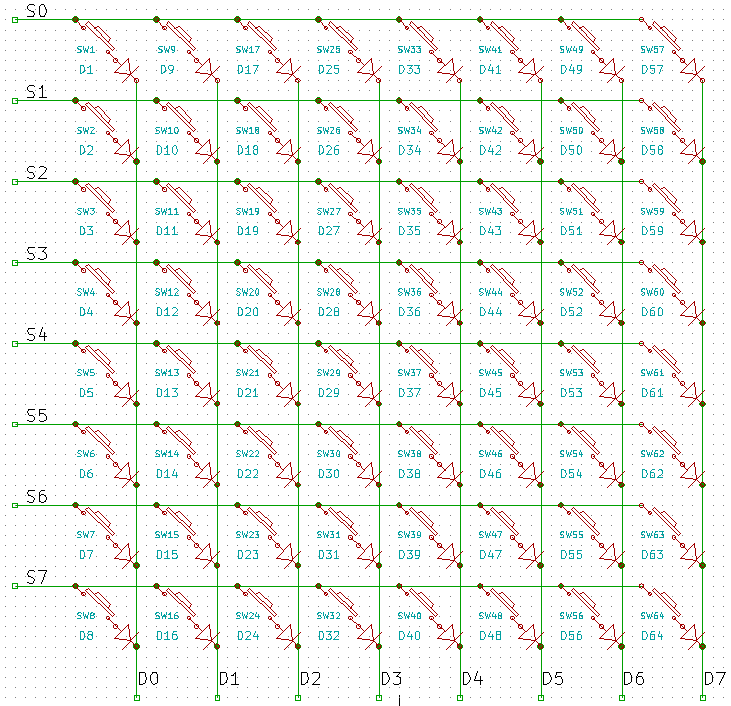

By adding a diode per-switch, full isolation can be achieved:

there is no shadowing, and multiple keys can be pressed and

correctly detected simultaneously. The diodes can be dual diodes

in SOT23 or some type of quad diodes. Here is a circuit I borrowed

from EEVBLOG.

In this circuit, the columns D[7:0] could be driven by a 3:8

decoder such as 74HC138 to save 5 more pins. The S[7:0] pins need

pull-ups.

BTW, an encoder or multiple encoders can be wired into this type

of matrix and can be read as just 2 more switches. An encoder is

simply 2 switches with a common pin.

Use I2C or SPI

Expanders

There are many 8 bit

and 16 bit I/O expanders. These allow the SPI or I2C

busses to access many switches, LEDs, etc. SPI at 4MHz is

generally much faster than I2C at 400KHz. These have the

added advantage of using much fewer wires to the front panel.

SPI can be bit-banged or use HW SPI.

As I mention above, SPI

and I2C devices that are controlled during interrupts need care

if shared with loop().

The MCP23017 is a I2C,

16 bit expander. At 400KHz, the 16 bits can be read in about 30

bit times (2.5uS) or ~77uS. $1.70. Not bad. But 80uS every 1mS

is 8% of the CPU processing power, just to read 16 switches. It

comes in a DIP for prototyping, SSOP, and an easy-to-solder but

large 28SOIC. There are weak pull-ups (100K) for switches.

MCP23008 is 8 bits.

MCP23S008 and 23S017 are SPI versions. Bit-Bang SPI is about 10x

faster than I2C.

There are I2C matrix

keypad expanders also available if many switches are needed. I'm

not familiar with these. Do they have proper anti-shadowing, N

key rollover, etc.? Most are QFN or BGA packages.

DIY SPI Expanders

This is a good approach

for high bit count mixed Input and Outputs.

The 74HC594 and others

are 8 bit output ports that can be wired to SPI. They can be

cascaded to add many more outputs. $.65. The 'HC595 is similar,

but has tri-state output OE/, and has no output reset. $.30. If

you need the outputs to be reset, use the '594.

For inputs, the 74HC165

will connect to SPI. The SH/LDn pin is asynchronous. The '166

has synchronous load. $.30.

The MISO pin needs a tri-state if it is shared with other SPI

devices. The SPI CS/ needs to be inverted with the '165. With

the '166 CS/ can be used directly, but it's synchronous, so a

SCK is needed.

There are many 8 bit

and 16 bit I/O expanders. These allow the SPI or I2C busses to

access many switches, LEDs, etc. SPI at 4MHz is

generally much faster than I2C at 400KHz. These have the

added advantage of using much fewer wires to the front panel.

The MCP34017 is a I2C

16 bit expander. At 400KHz, the 16 bits can be read in about 30

bit times or ~80uS.

CharliePlexing

Charlieplexing is when

you minimize I/Os for multiplexing LEDs or switches. LEDs lend

them selves to this nicely because they have built in diodes.

And just one resistor per pin.

Switches require a

diode per switch.

Analog keypads

My Whole House

(Multizone) audio system uses remote, wired, keypads in several

rooms. These are analog keypads, read by the processor ADC. Each

keypad uses up to 8 buttons each. Each uses one ADC pin. The

buttons select 0 to 7, 1K resistors in series. There is a 4.7K

pull-up on each ADC pin. So the ADC reads the resistance of the

keypad, quantizes it to the nearest 1K value, and de-bounces it.

The keypads are simple,

and only need 2 wires. GND and SIGNAL. Since they can be ~50

feet of twisted-pair wire away, I also use 1K resistors in

series with each for EMC, ESD, etc. So the actual resistance

measured is 1K to 8K.

This technique can be

used locally as well. 2 wires to the keypad, one resistor per

switch. One ADC input. Easy-peasy.

I wrote this in STM32

code, not Arduino. It works well with good debouncing and

decent quaality switches. The only problem I had is that one of

the keypad boxes is outdoors. Every year or 2, I'd have to

replace or clean the buttons. I finally found some cheap / good

waterproof buttons on Amazon.

Analog Encoder

Can a similar trick be

used to read an encoder? I wired 1K and 2K resistors across the

A and B contacts of an encoder, and used a 5K (4.99K) pull-up.

You need to detect 2 switches, so the switch resistors should be

binary values. I use 1K and 2K.

- With both A and B

OFF: 3K

- With A ON: 2K

- With B ON 1K

- With both ON 0K

Here is the code. I'm

still deciding if this is how I want to go.

/* Reads analog encoder. A has 1.0K, B has 2.0K, pull-up is 5K, cap is .1uF

Works with encoders that are 4 states per click: TT or bourns

OFF - A - Both - B 0-1-2-3

OFF - B - Both - A 0-3-2-1

Idle, 0, both OFF : 3K / (5K + 3K) = 3/8 * 1023 = 383

A, 1 ON : 2K / (5K + 2K) = 2/7 * 1023 = 299

B, 3 ON : 1K / (5K + 1K) = 1/6 * 1023 = 170

Both ON, 2 : 0K / 5K + 0K) = 0/5 * 1023 = 0

Tolerance of +/- 30 counts seems to work well.

Reads ADC once, checks against limits, assigns state.

Then encCount detects transitions from Both to A (increment)

or Both to B (decrement).

To change direction, change encCount ++ to -- and vice versa

*/

void readEncoder(void){

#define EO 383

#define EA 299

#define EB 170

#define EAB 0

static char encSt, encStD1, encStD2; // idle. 1:A, 2:BOTH, 3: B

#define tol 30 // +/- Tolerance (range for valid encoder ADC values

int encAn1 = analogRead(0);

int encAn = analogRead(0);

if ((encAn - encAn1) < 20 && (encAn1 - encAn) < 20){ // Read twice for stable V

if (encAn > (EO-tol) && encAn < (EO+tol)) { // Idle

encSt = 0;

}

if (encAn > (EA-tol) && encAn < (EA+tol)) { // A

encSt = 1;

}

if (encAn > (EB-tol) && encAn < (EB+tol)) { // B

encSt = 3;

}

if (encAn < (EAB+tol)) { // Both

encSt = 2;

}

if (encStD1 == 2 && encSt == 1) { // Transition BOTH to A

encCount --;

// Serial.print( "encCount = "); Serial.println( encCount);

}

if (encStD1 == 2 && encSt == 3) {

encCount++;

// Serial.print( "encCount = "); Serial.println( encCount);

}

encStD2 = encStD1;

encStD1 = encSt;

}

}

It works pretty well,

but not completely reliable. I decided this isn't a great

idea since it only saves one I/O pin. Instead, I'll use a

keyboard matrix with diodes. The encoder is just 2 more switches

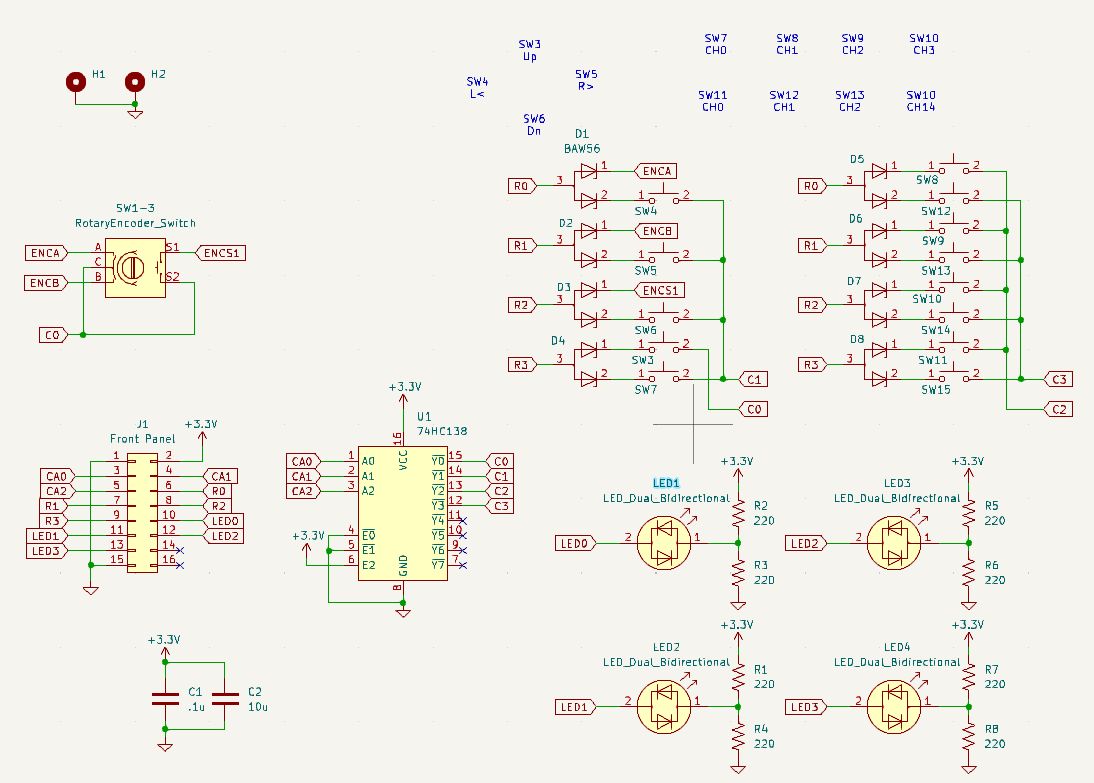

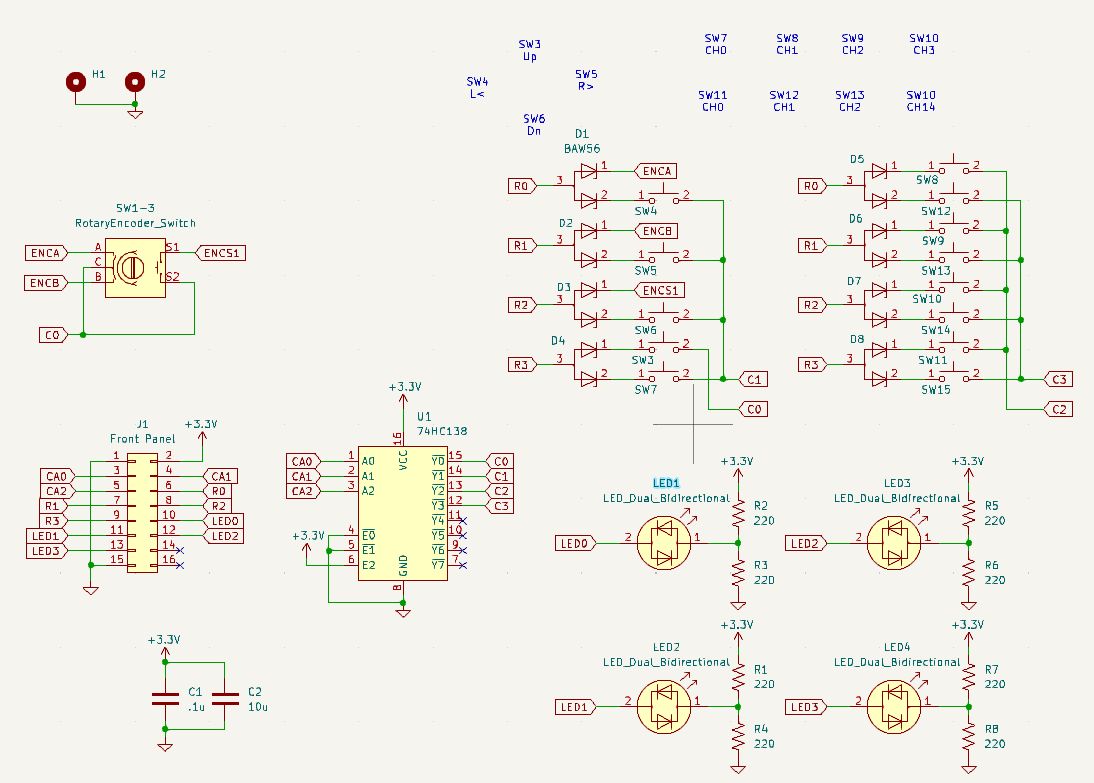

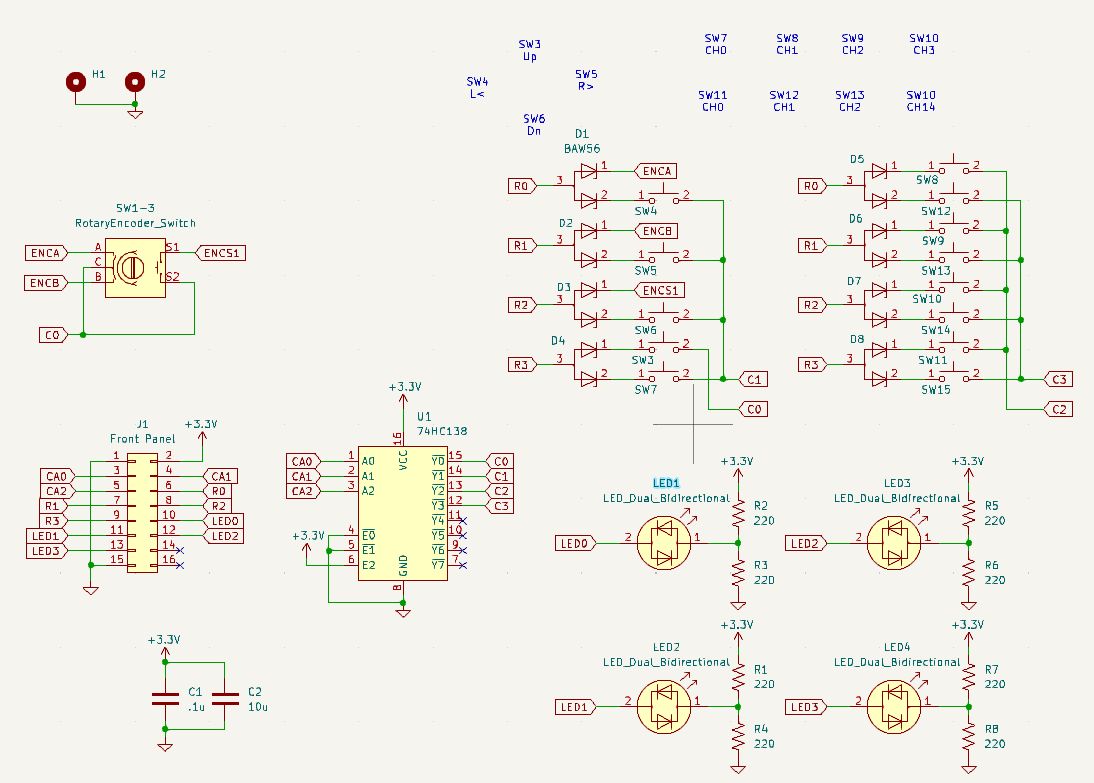

in the matrix. Here is the schematic for the front panel

board for the Quad-SMU project. Because the Encoder can have its

two switches closed at the same time, diodes are needed on it.

The other diodes are just to allow multiple simultaneous button

presses to be detected. It has:

- One Encoder with

switch

- 13 momentary

switches

- Switches matrixed

with one diode per switch.

- 74HC138 2:4 decoder

to save 2 I/O pins

- 4 bi-directional

GN/RED LEDs

- 16 pin connector to

CPU board

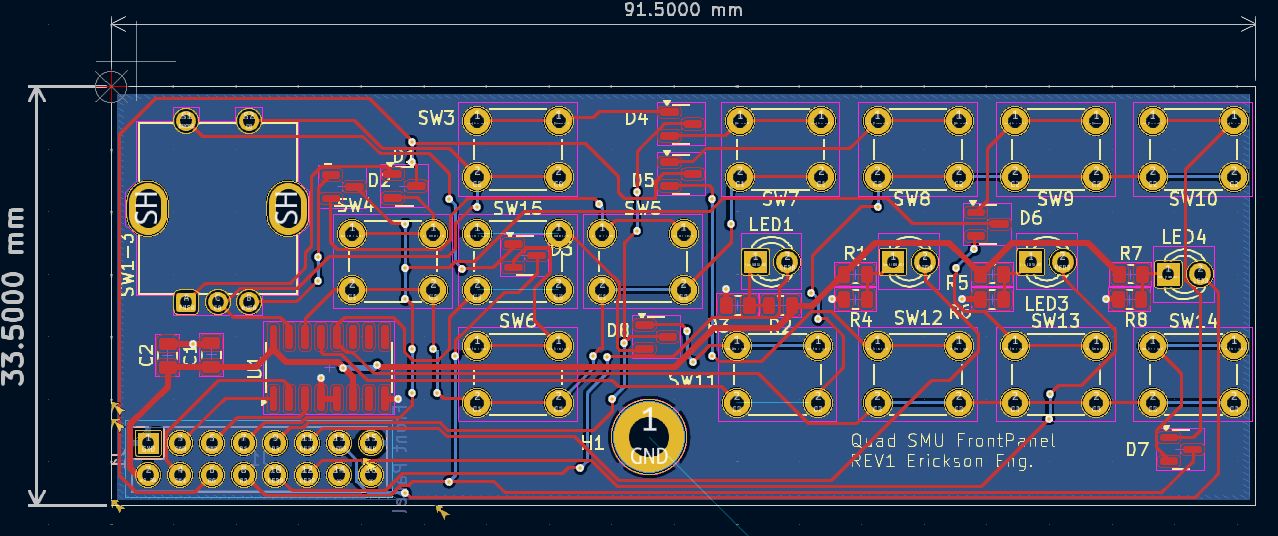

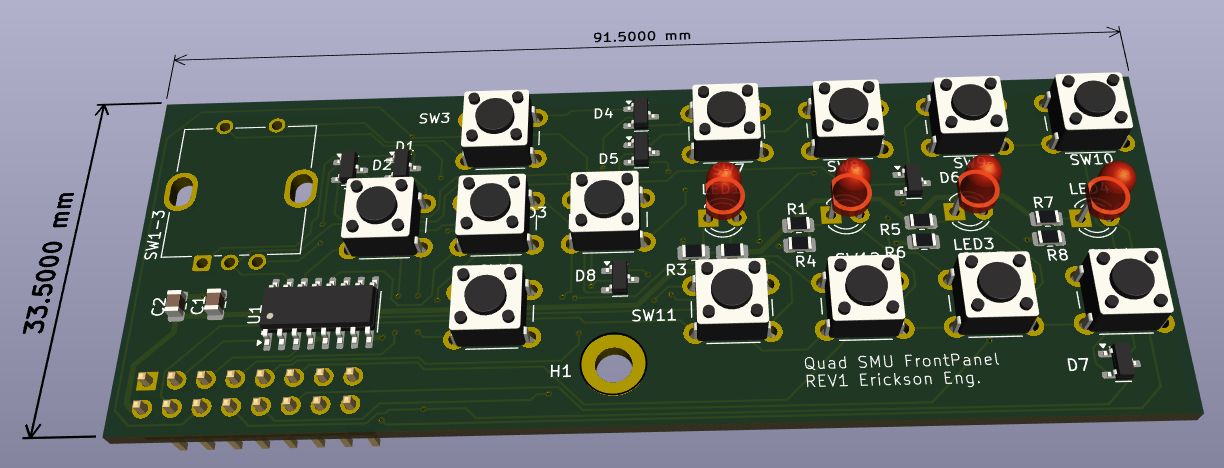

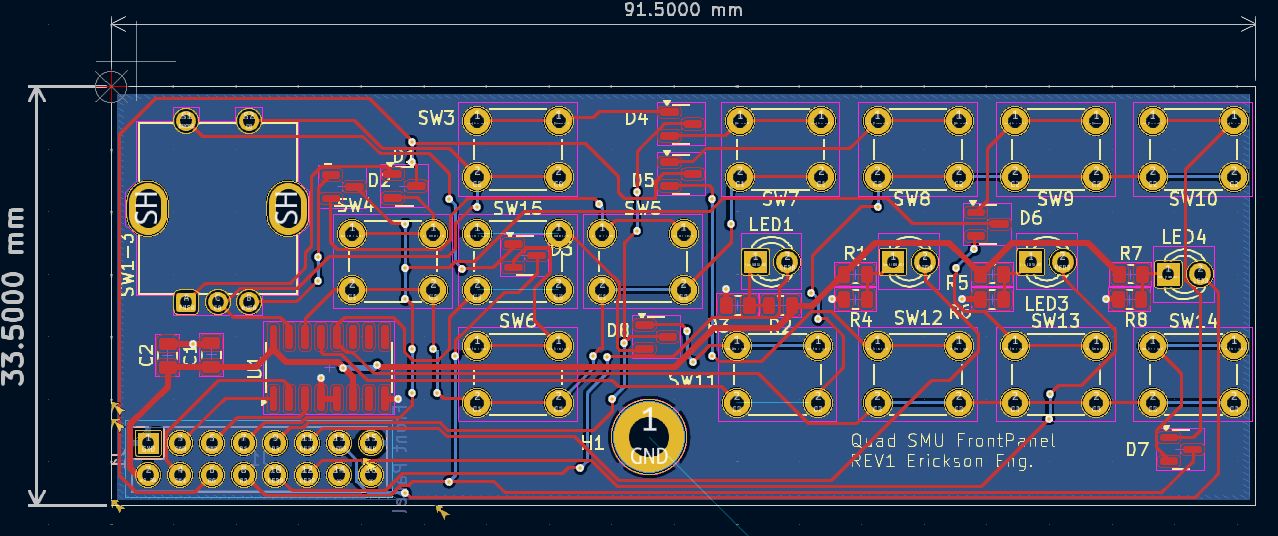

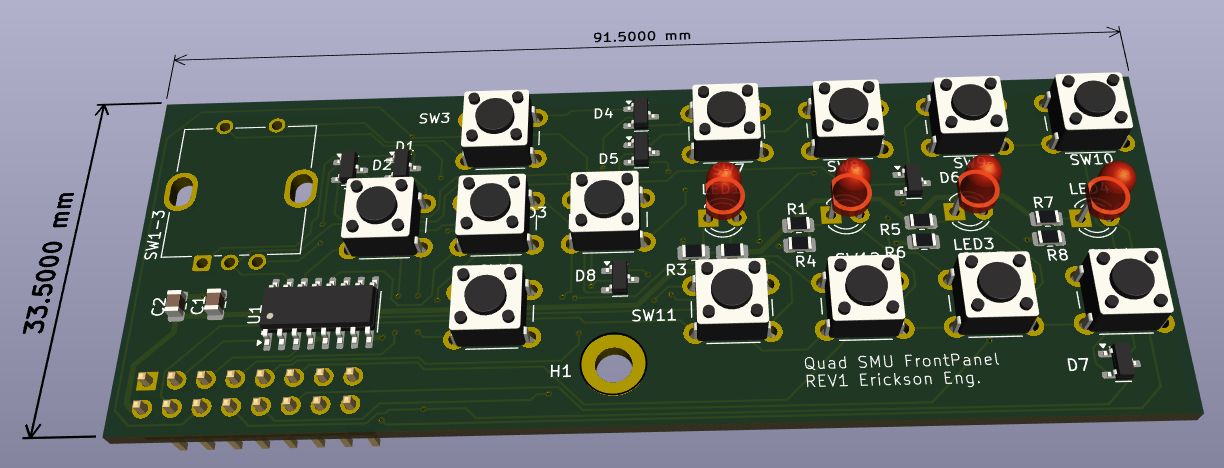

Here is the PCB so far.

Back to Dave's Home Page

This page was last updated 11/30/2024