DIY SMU: Source

Measure Unit Page 4: New Case, CPU, SCPI, Testing

The Schematics, PCB

files, and BOM are here

Page 1: the Analog part

Page 2: the Digital part

Page 3: Board

Bringup

Page 5:

Board Bringup 3

EEVBlog

Forum Page

Youtube

Videos

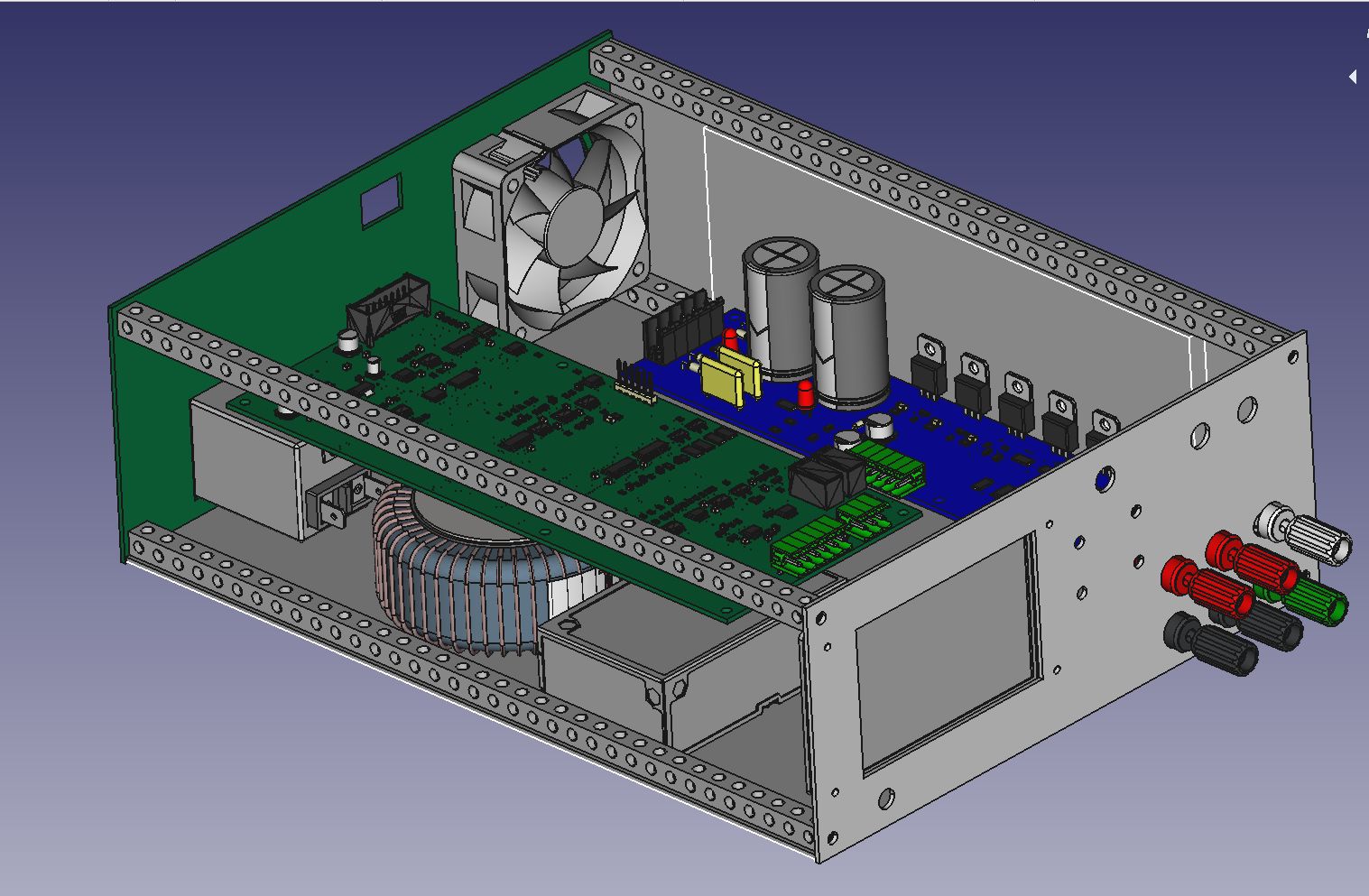

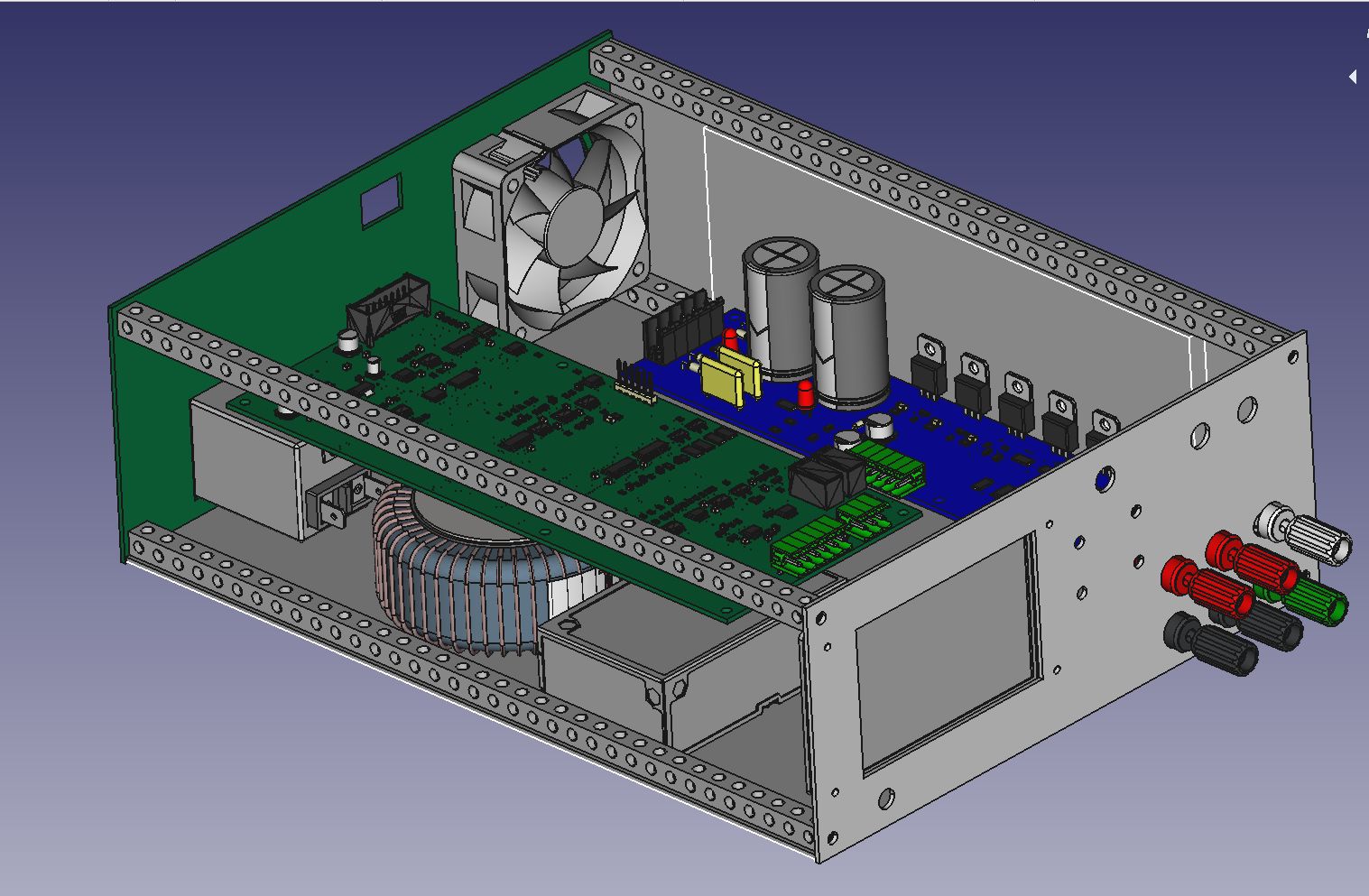

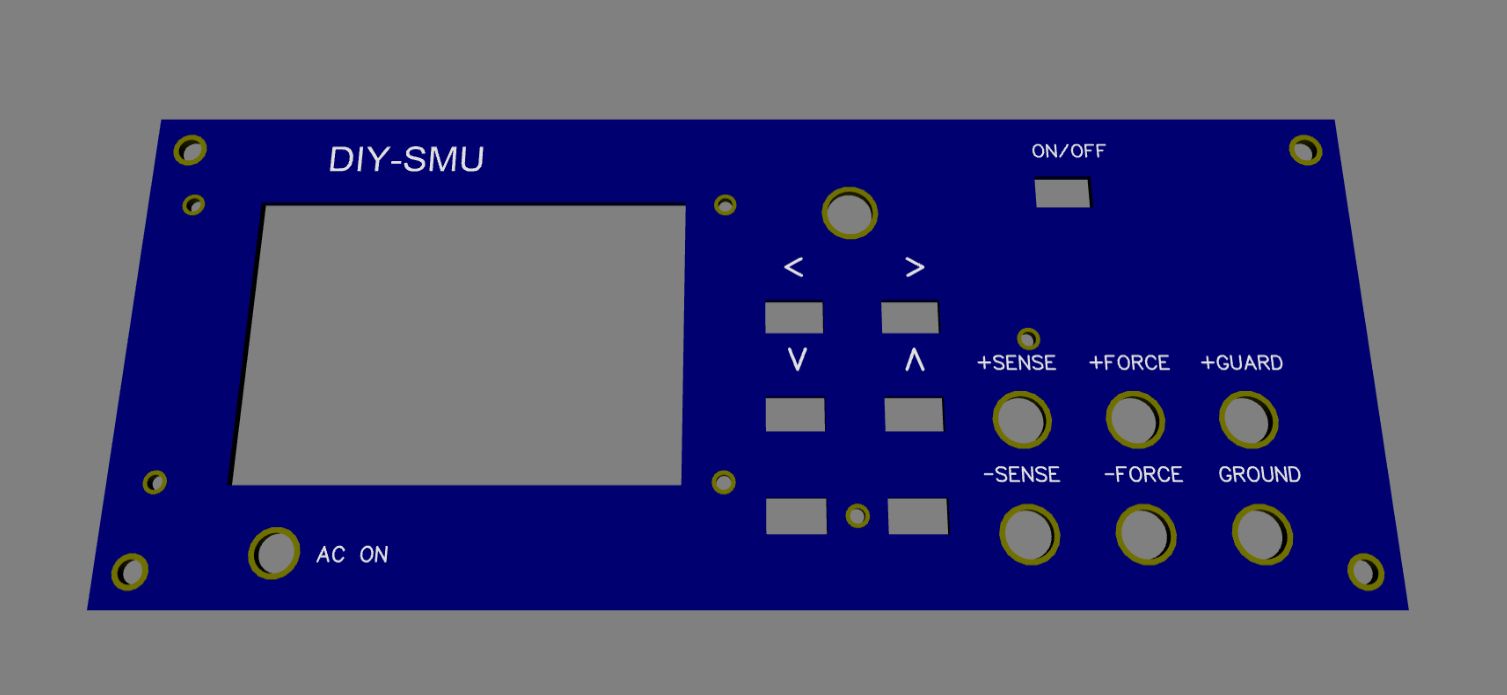

New Enclosure

I'm working on the new 2U

Half-rack (8.5" wide) case. Thanks to an ad in Nuts and Volts

magazine, I learned about GoBilda

hardware: an Erector Set for adults. In addition to motion

control hardware for robots, they make the 1106 off-the-shelf

rails that are nice for building boxes. These are 8mm square rails

with 4mm holes on 8mm centers. The ends are threaded for M4

screws. To build a box, the flat front and rear panels can screw

to the rails, the bottom and sides can bolt on with screws and

internal nuts. The top cover needs to mounted with some type of

blind screw threads. Current thinking is to drill and tap some of

the 4mm holes to accept M5 screws.

The top, bottom and sides are simple rectangular sheet metal with

a few mounting holes. Holes on the bottom are for mounting the

various components. These will be 16AWG (0.060", 1.5mm) 6061

aluminum. I generally cut rectangular sheet aluminum on my

table saw using a soft-metal carbide blade.

The front and rear are either hand-made sheet metal, PC boards, or

custom aluminum panels such as PCBWay. I plan to use a PCBWay

aluminum panel for the front. It solves the problems of front

panel finish color (using soldermask) and labeling (silk Screen).

Color choices are somewhat limited for PC boards and PCBway, but

so be it. As an EE I like to do front panel layout using PCB

design tools.

I have built similar chassis using 1/4" square aluminum myself,

but the rails are a pain to make: lots of machining, drilling,

tapping. My thanks to GoBilda for doing the hard part. 280mm

(11.0") rails are $6 each, and they come in different lengths.

Parts are on order.

For the front panel jacks, I plan to use 8mm (5/16") holes for

5-way binding posts. These allow more connection choices than

Safety Banana jacks, but are not as safe. The 6 holes can be

enlarged with a step-drill if you prefer safety jacks or other

connectors. For connections I plan to use the 2x3 arrangement that

Agilent uses. It is similar to what Keithley uses on their rear

panels, except I replace their Guard sense (not super useful) with

a Chassis Ground.

The heat-sink and mounting for the Amp board need to be raised up

a bit to clear the 8mm rail. 0.5" board spacers will do the trick.

The heat-sink will be 0.250" x 2.5" 6061 bar stock, cut to length,

drilled and tapped for the TO-220 transistor mounting hardware.

This will be screwed to the chassis-side for mechanical support

and thermal contact.

Open issues: Finalize front panel controls, lay out the Front

panel / CPU board, paint finish for top, sides, bottom, rear. And

cooling air holes.

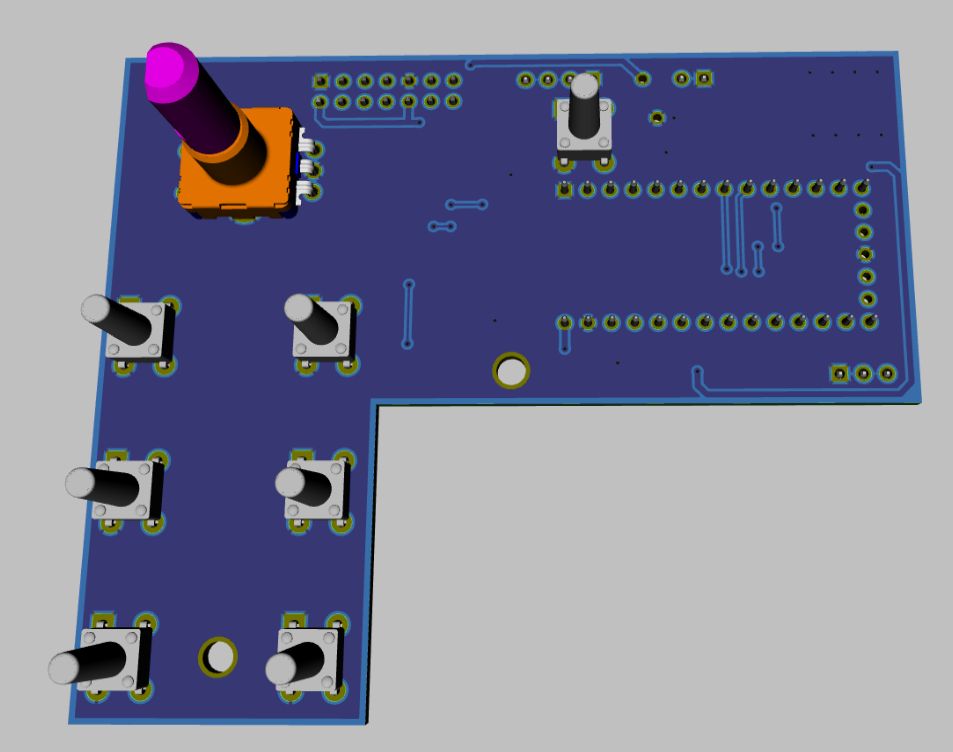

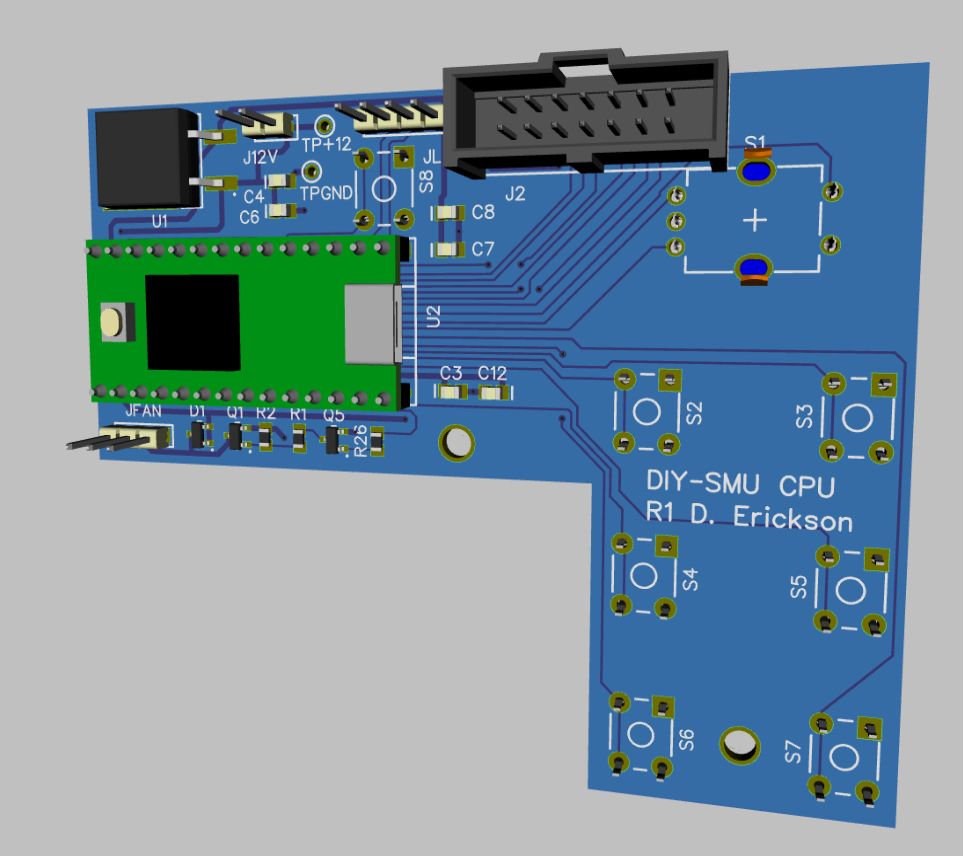

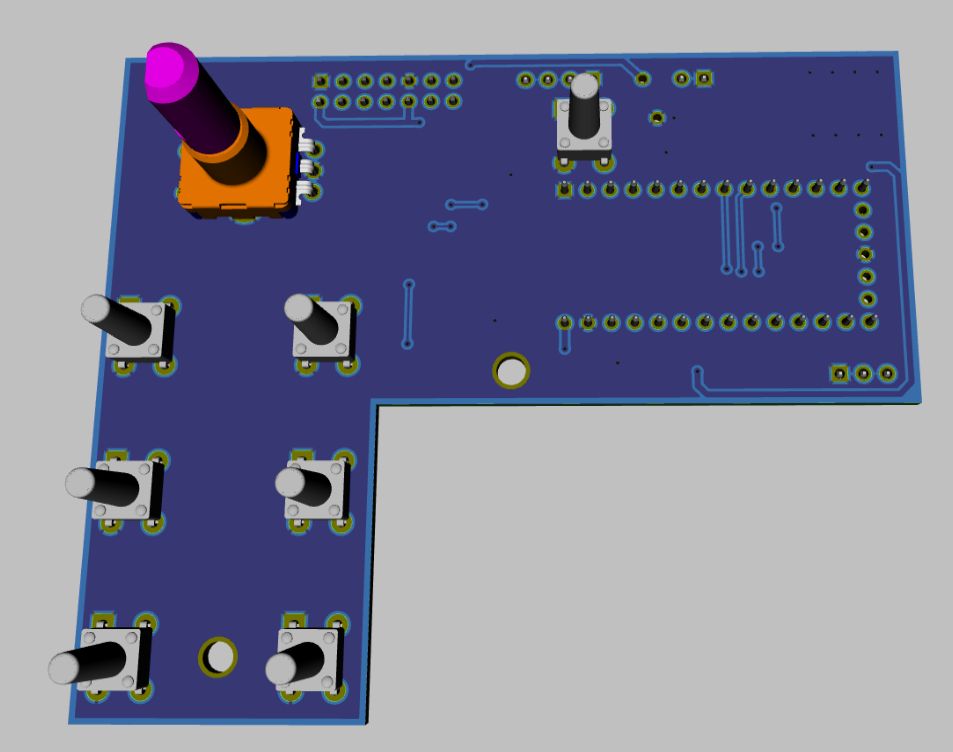

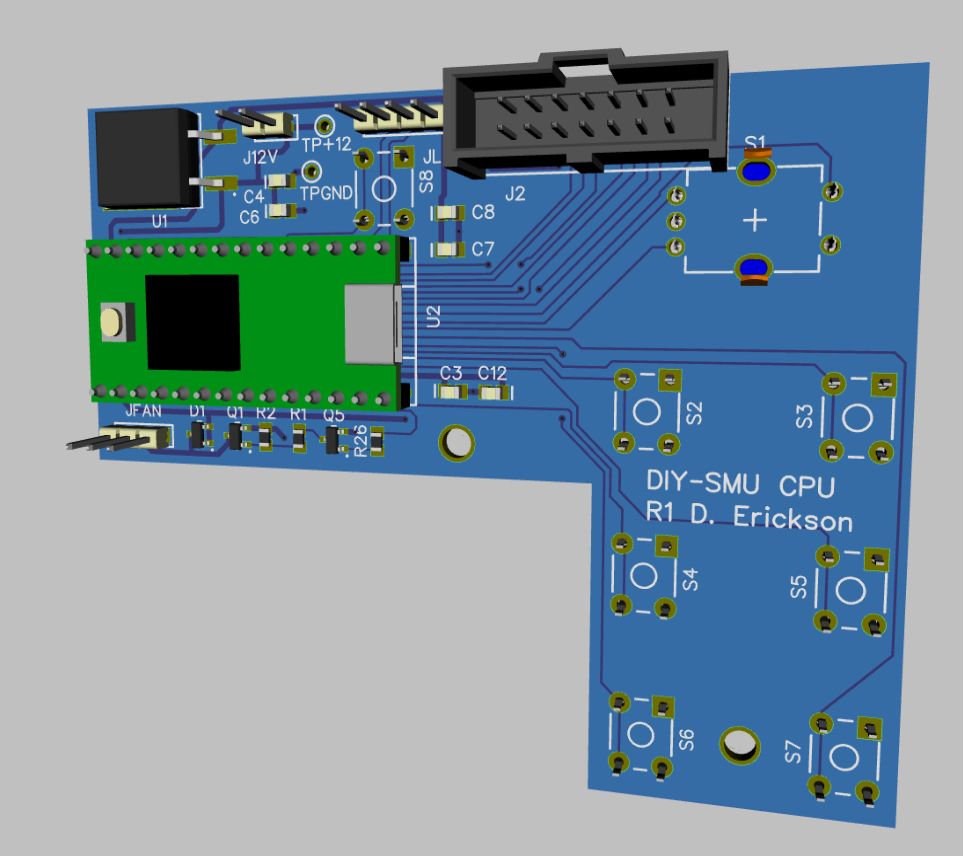

CPU and Front Panel

Board

Now that I have decisions

about the front panel size and shape, control positions, and jack

configuration, it is time to design and lay out the CPU board. It

will have the Teensy Processor and the front panel encoder and

buttons, and power, Main Board, and fan connections. It fits

between the Nextion Display and the Instrument banana jacks. This

board takes in +12V and has a linear regulator for +5V. It has a

simple fan control from the processor. Since the processor can

calculate the power being dissipated in the heat sink, it can

figure out when to turn the fan on. The fan driver will run the

12V fan at low voltage (5V) and low speed when not dissipating

much power and will turn it on to +12V when over a few watts are

being dissipated.

I chose thru-hole, 6mm switches since they are multiple sourced,

and many button styles and heights are available. I prefer the

look of rectangular buttons, but have no easy way to make small

rectangular holes in sheet metal. So for home-made panels, will

use round buttons and holes. I can use the nicer rectangular

buttons when I get machine-made front panels.

The CPU board front side has the controls, back side has the

Teensy 3.2 processor, voltage regulator, and the various

connectors.

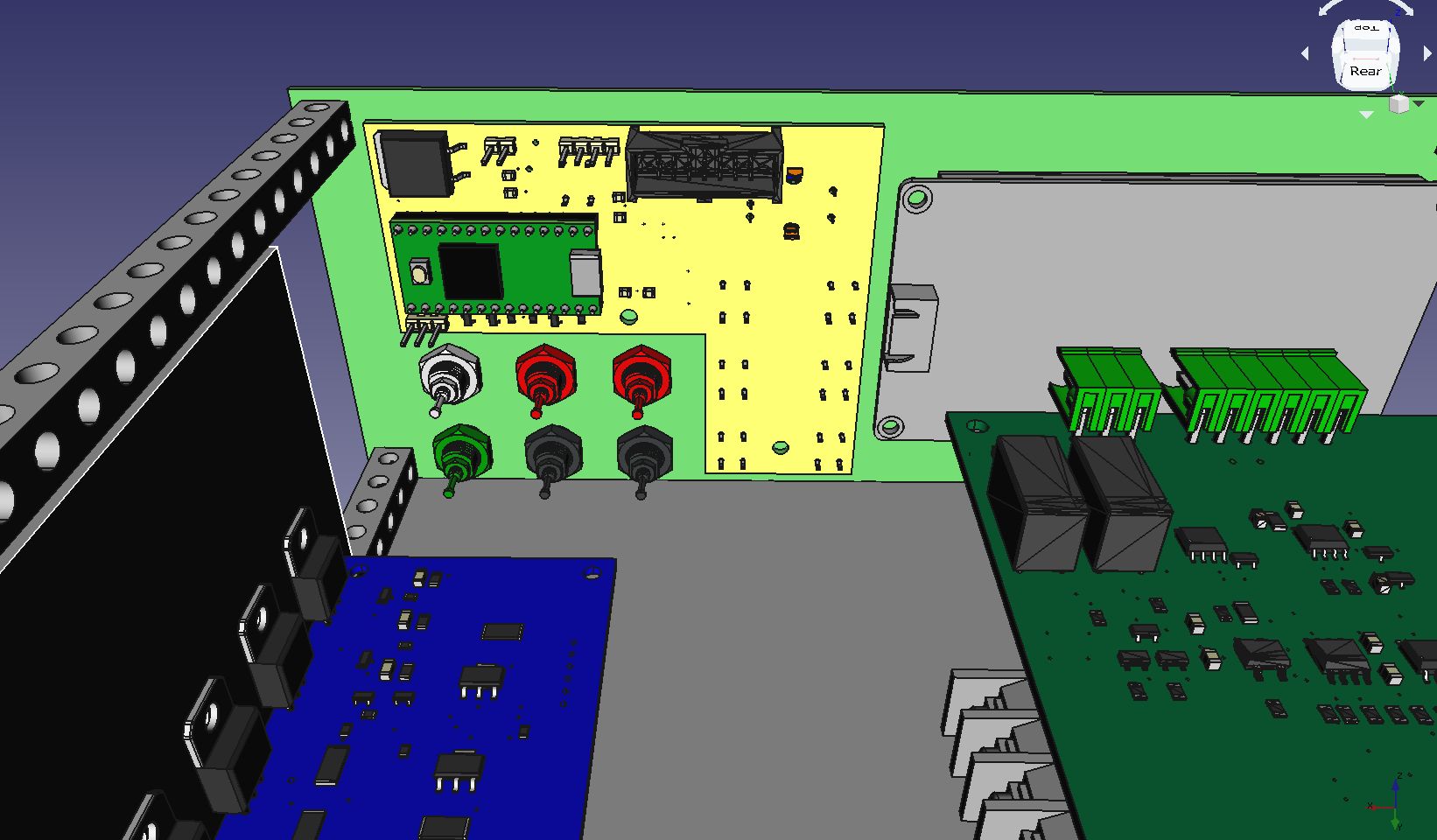

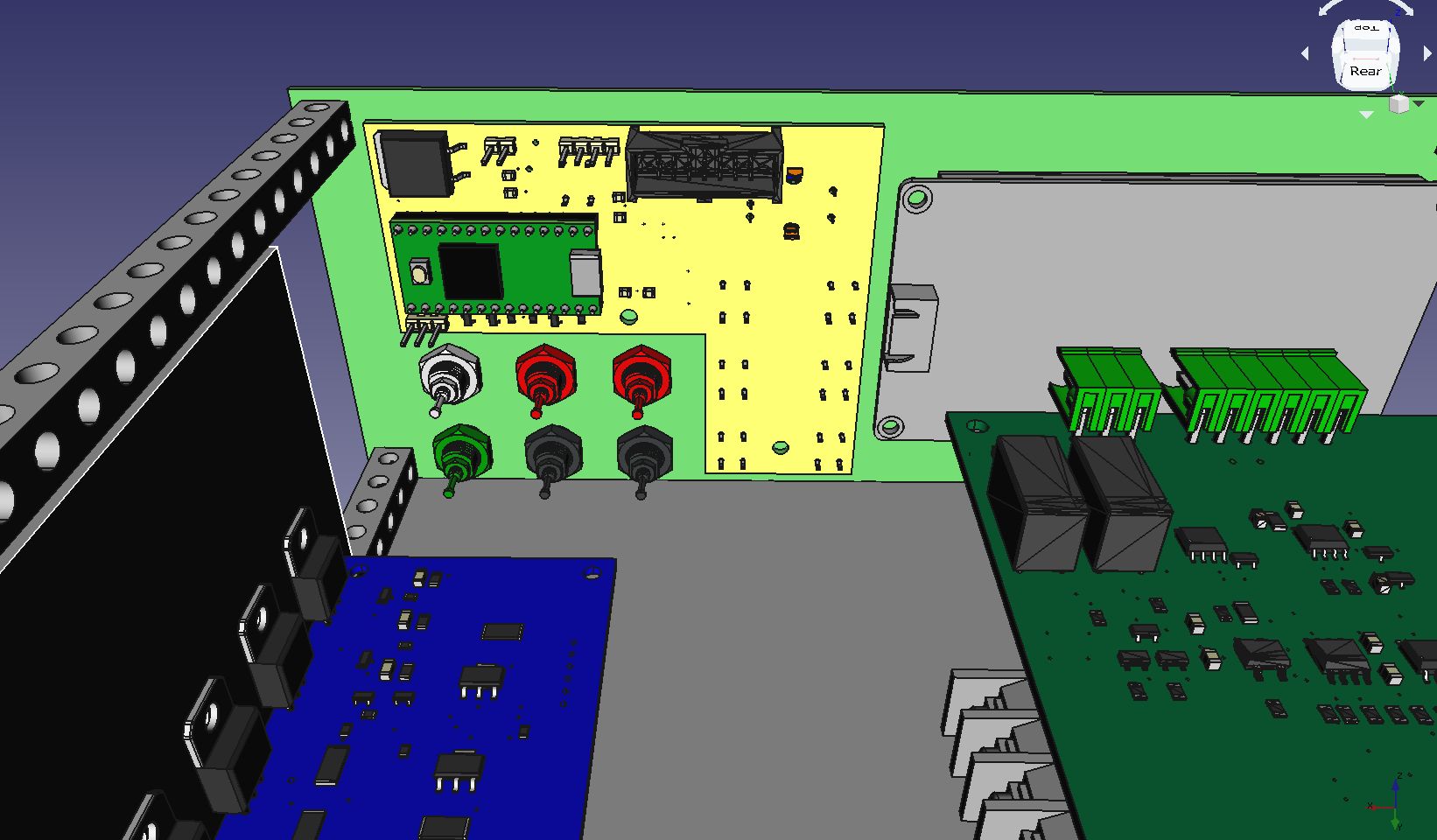

Here is the CPU board inside the new case. It fits nicely in CAD.

CPU Boards and parts are on order. Designing the hardware was the

easy part. The part that scares me is to port the firmware from

Arduino Leonardo to Teensy. I use some chip-specific timed

interrupt routines for reading and de-bouncing the switches and

encoder. Have never moved this code to Teensy, so I need to pay

the price for writing it as non-portable code. Ah well.

- Nextion Display

- SPI code. Could

bit-bang initially to get it working.

- Controls: Buttons

and encoder (needs 1ms timed interrupt)

- Fan control

(calculate power, turn on Fan)

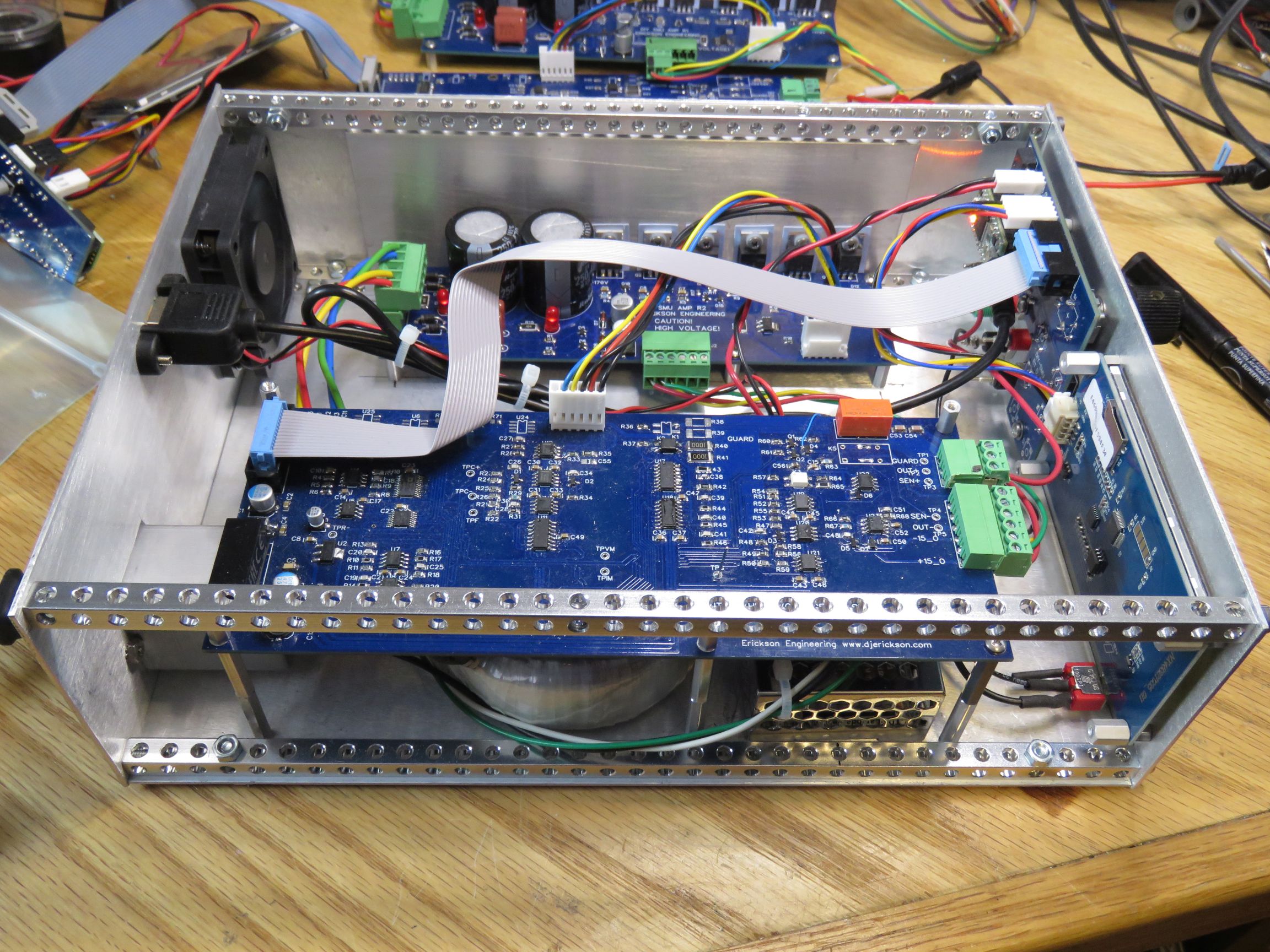

Here is the prototype

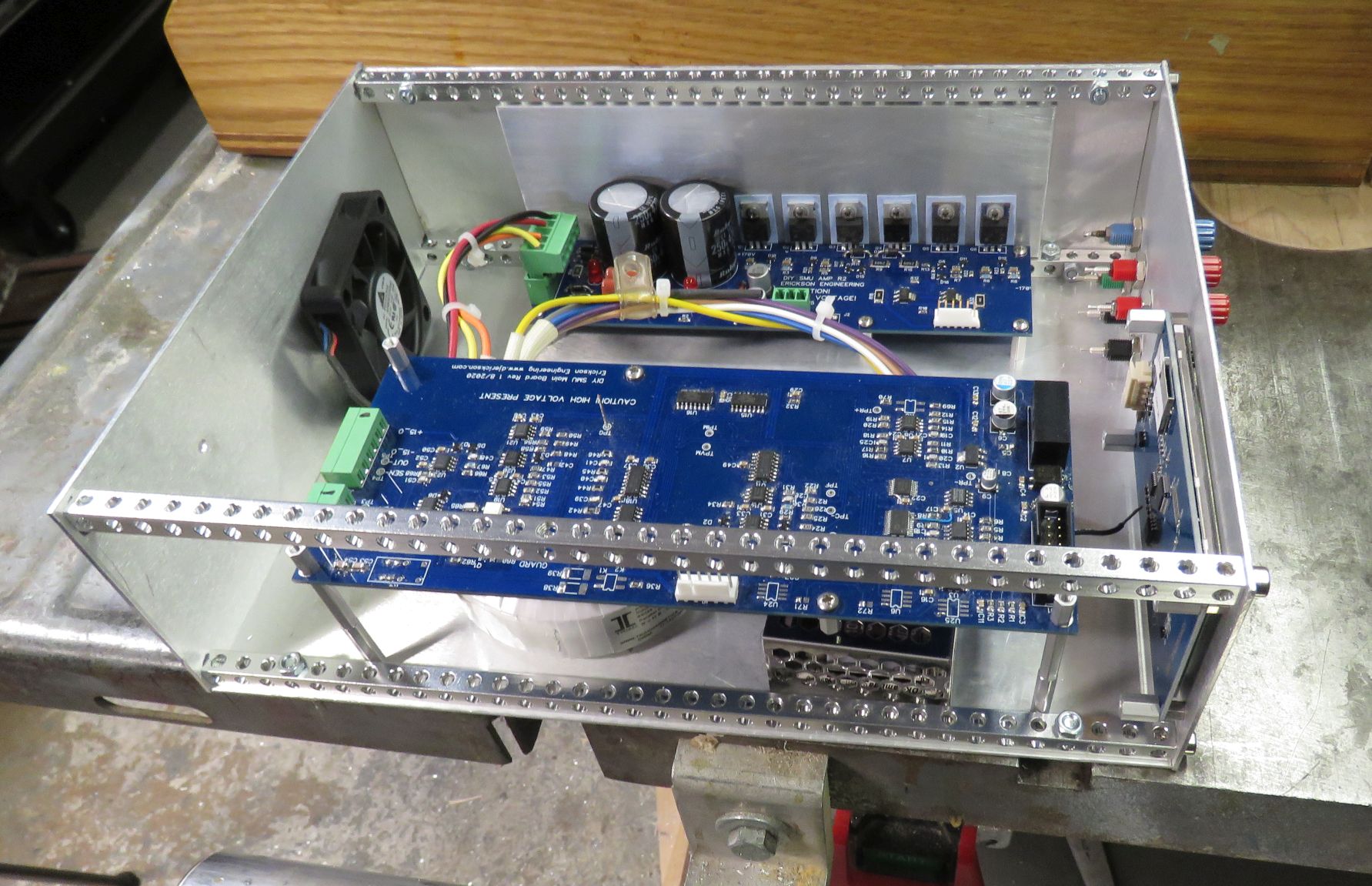

enclosure with front, rear, one side and bottom. Gobilda.com

makes the 8mm corner rails. The 6 sides are rectangular, flat

0.060" (1.5mm) sheet aluminum. I patiently await the new CPU

board.

While waiting for the

CPU boards, I spent a few hours porting the code to Teensy and

getting it basically working. This required:

- Defining the I/O pin

numbers for the new board

- Moving the 1mS

interrupt from the AVR timer to a Teensy timer

Fortunately my 2019

Polysynth

project already had a timed interrupt routine for Teensy, so it

was easy to just copy the few lines of timer setup code. And it

worked! I had to fix one minor bug which the AVR compiler

called a warning but the Teensy compiler called an error. It

looked like 99.99% of the original code would just work. So

instead of forking off a new build for Teensy, I just use #define

AVRMEGA or #define TEENSY and where needed, #ifdef commands to

make the code do both. So far so good.

When it compiled OK, I ran it on a bare Teensy 3.2, and it output

the correct serial messages! I connected a Nextion display (just 4

pins) and Nextion worked. Porting to Teensy was much easier than I

had expected. My thanks to Seitan for making his Nextion library

portable.

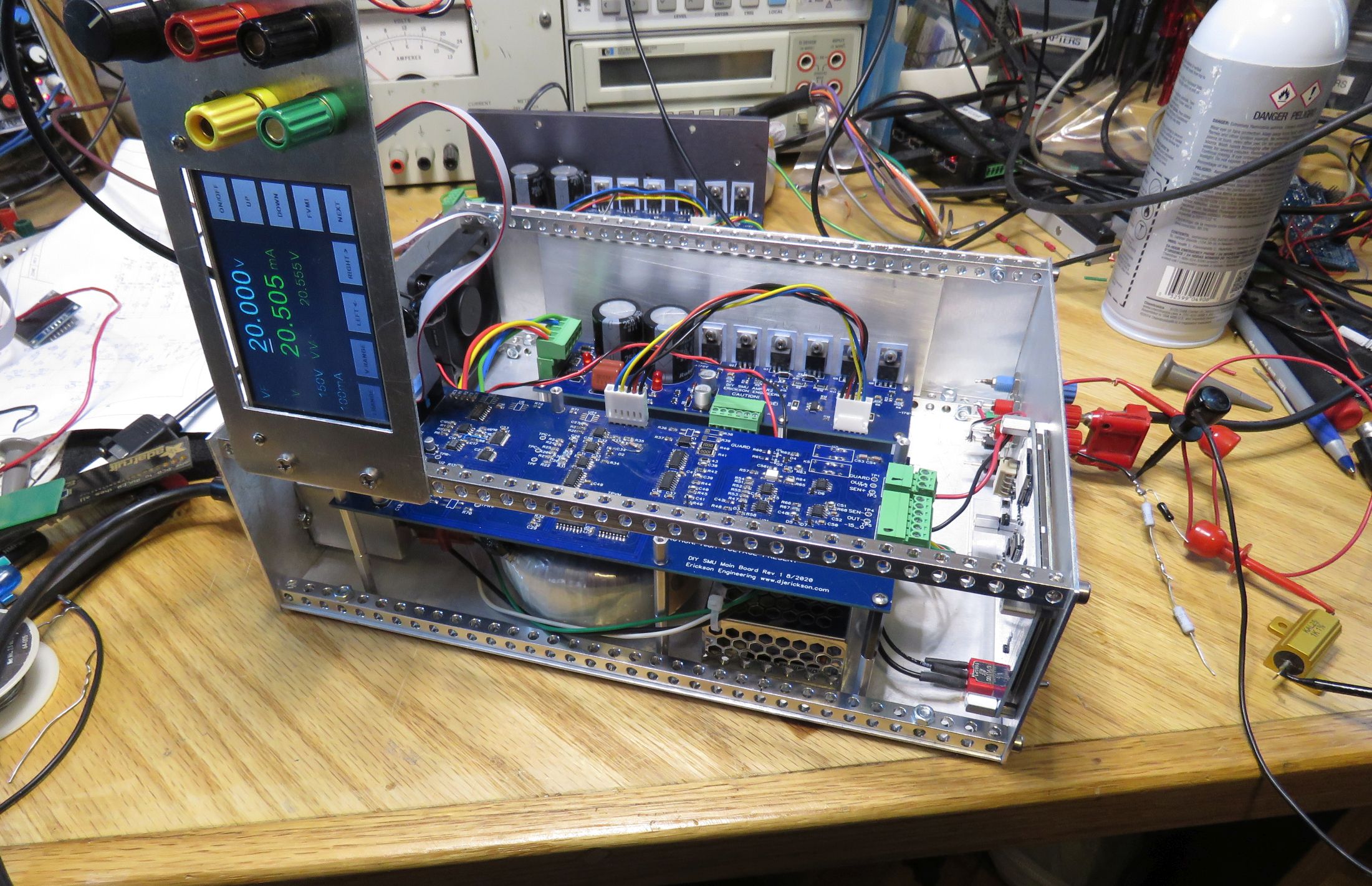

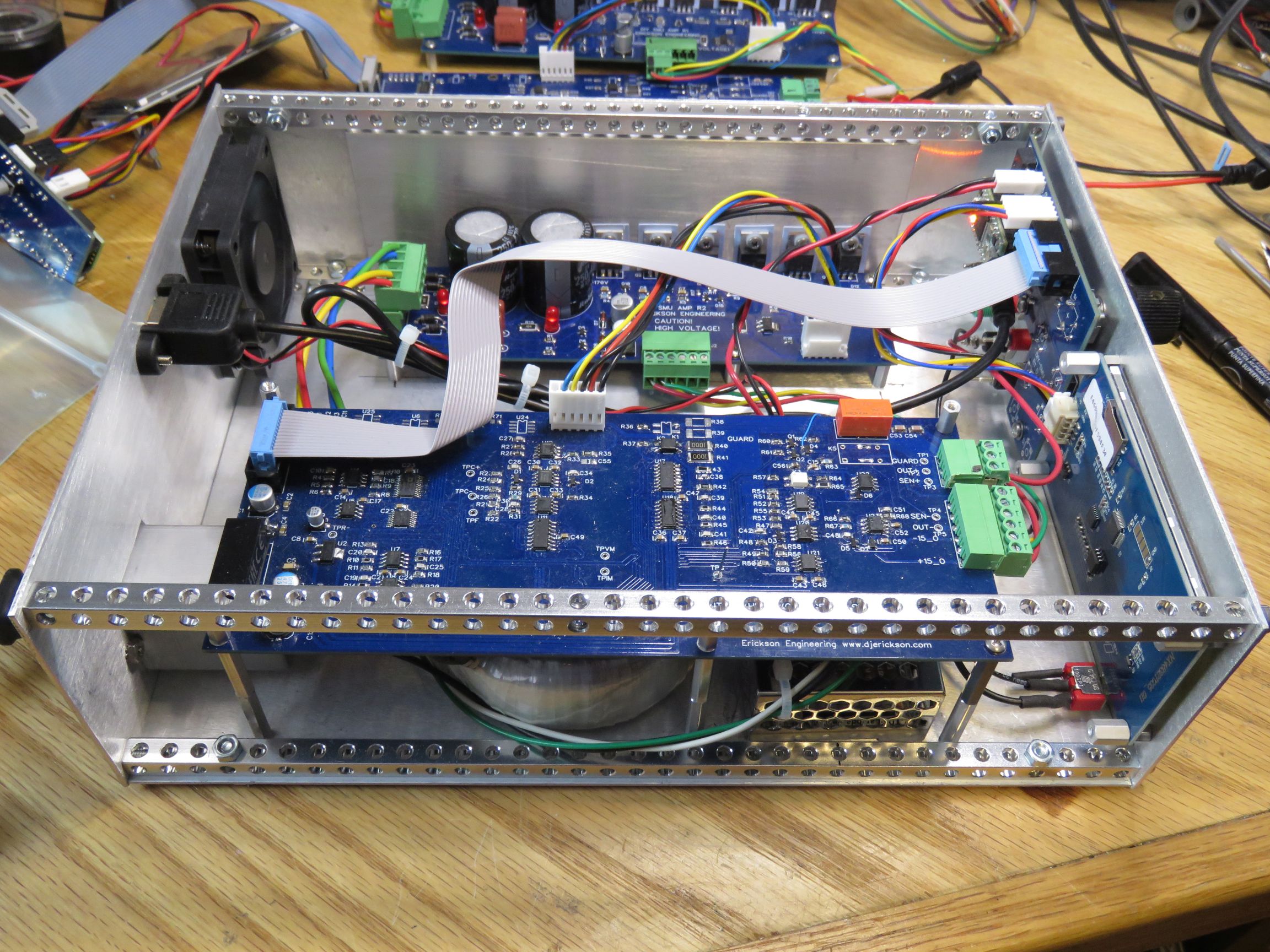

All the major components are installed, except the new CPU board.

So to get it working, the old front panel and CPU board are

mounted at an awkward location.

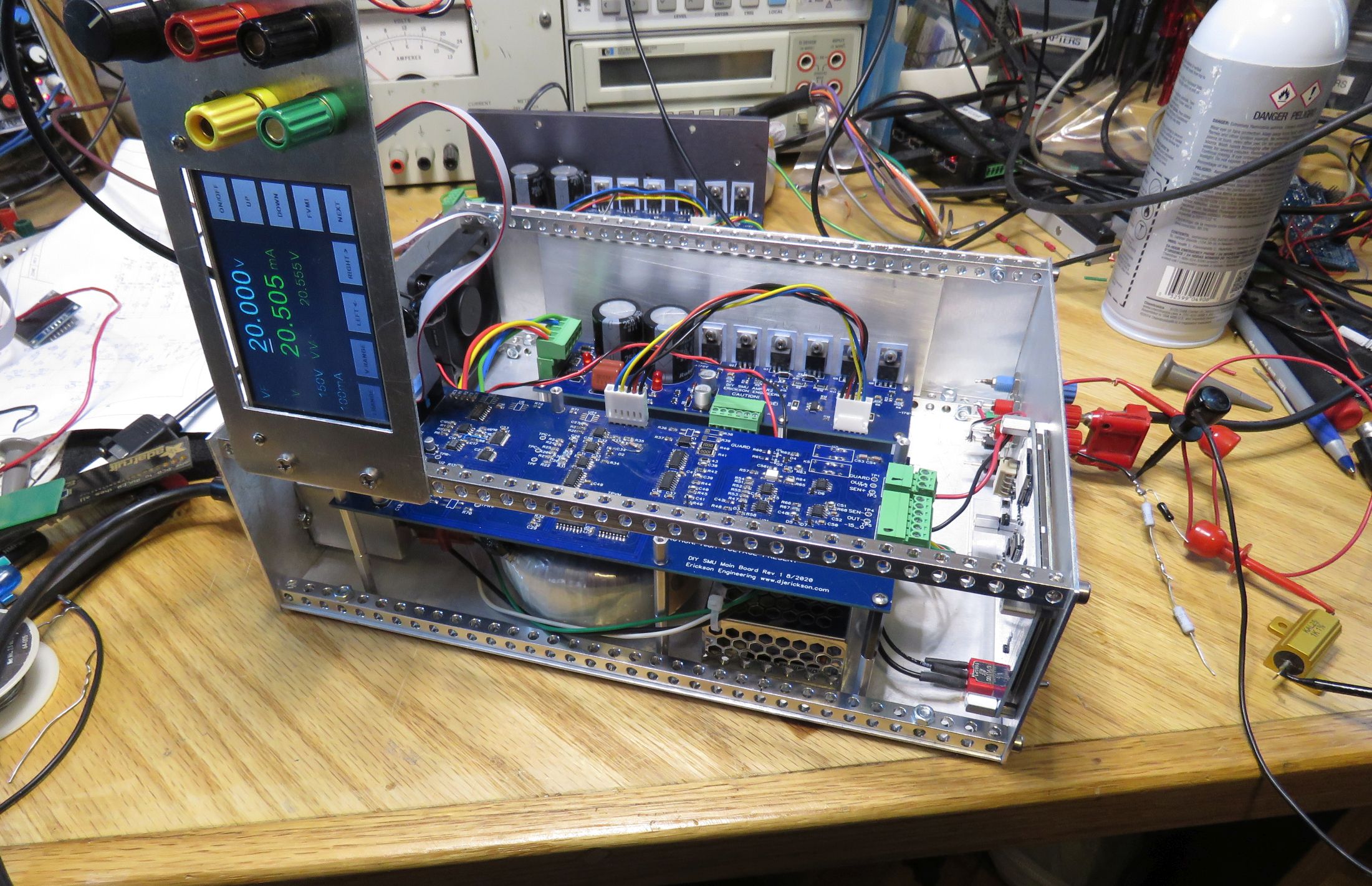

2/8/21: The bare CPU boards arrived from PCBWay today. The 5V

regulator, processor and Nextion display came right up, and the

SPI pins had activity. I connected a 14 pin ribbon cable to the

Main board and the encoder and buttons worked. It actually

controlled the SMU, and it works, time for a beer! Tomorrow I

drill holes in the front panel for the controls and mount the

sucker. I found a few small bugs in my code that I was able to fix

quickly. There is nothing like porting your code to a completely

different architecture for finding bugs.

When you use a Teensy and provide it with local +5V power, like I

do, don't forget to cut the power jumper under the USB connector.

Otherwise Your +5V will try to power the USB power and draw a lot

of current.

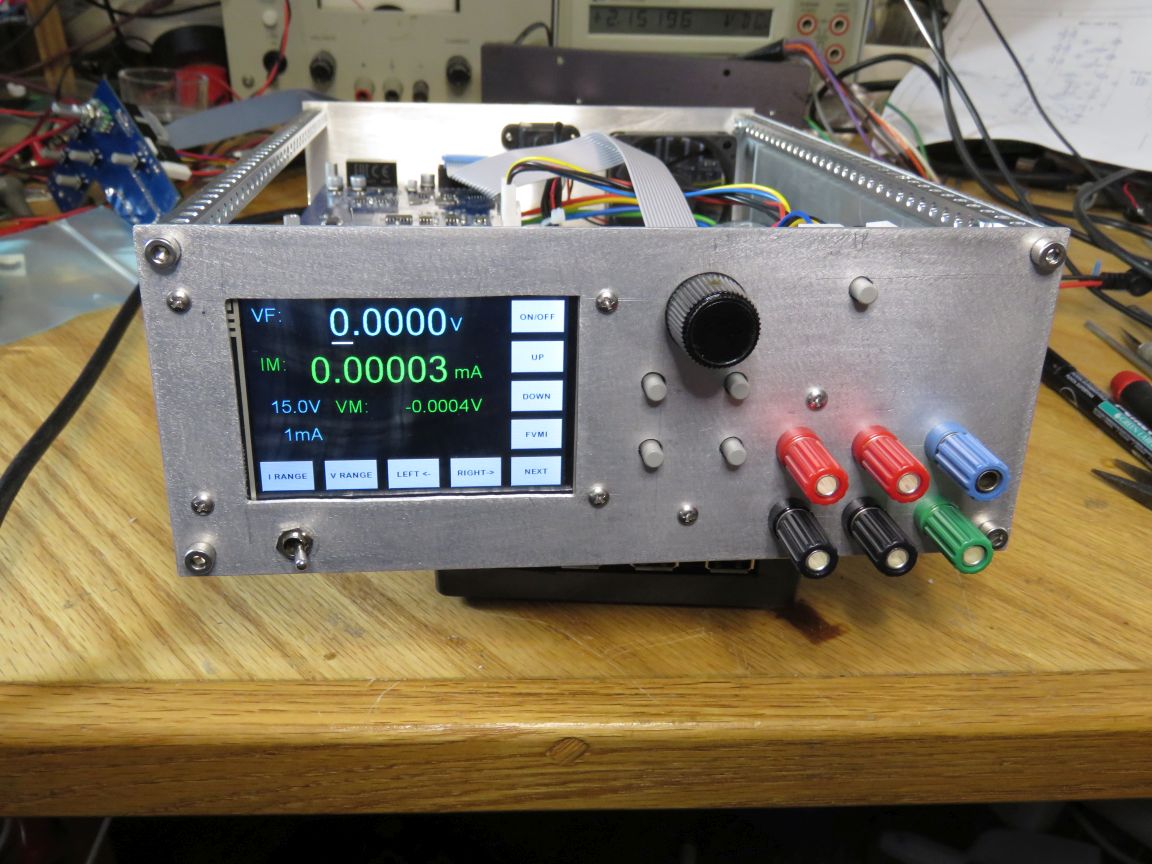

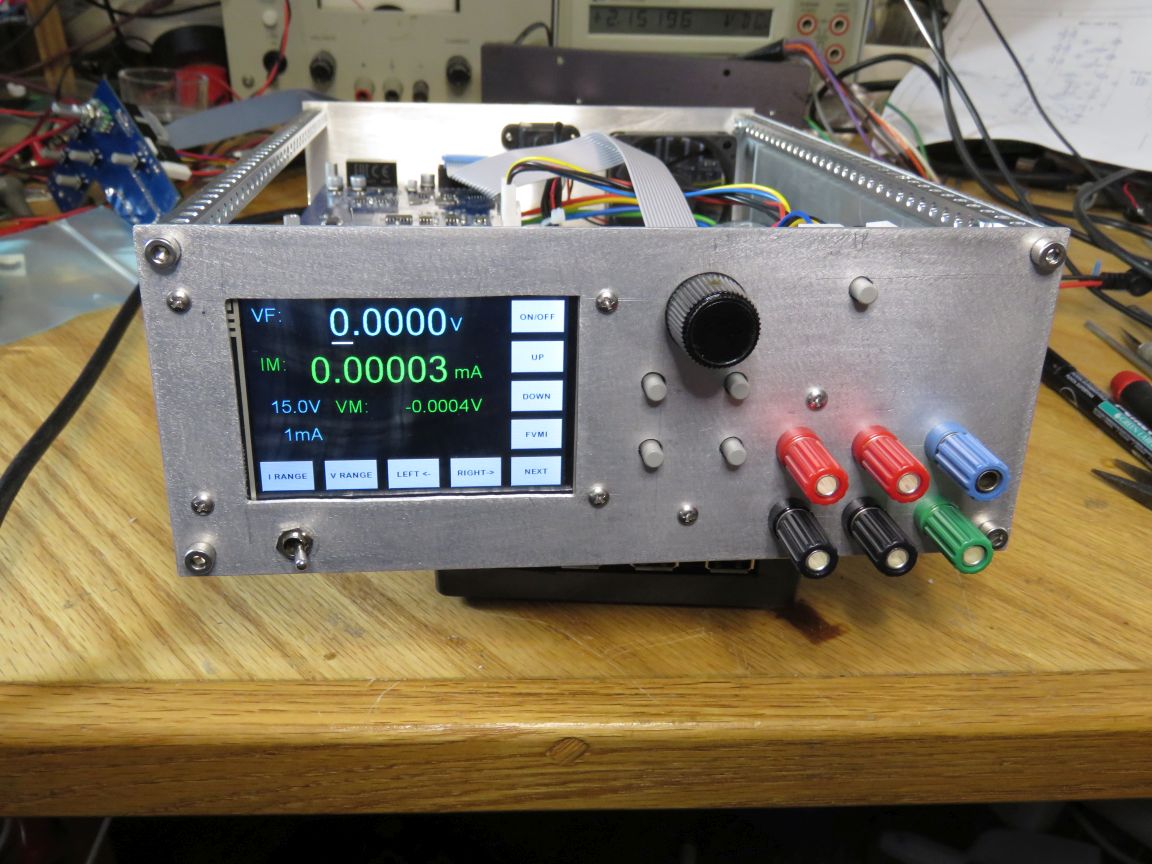

Here is the new case with the new CPU, all cabled up and working.

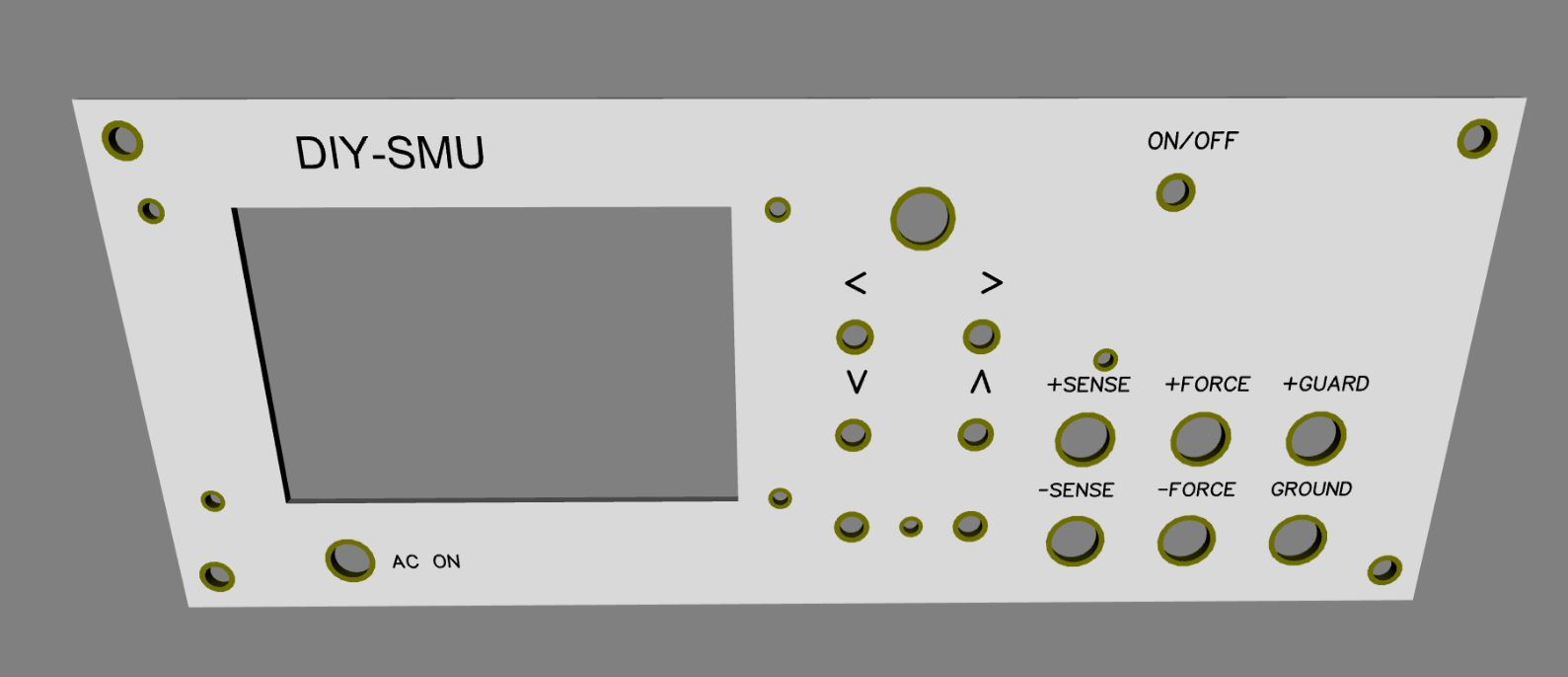

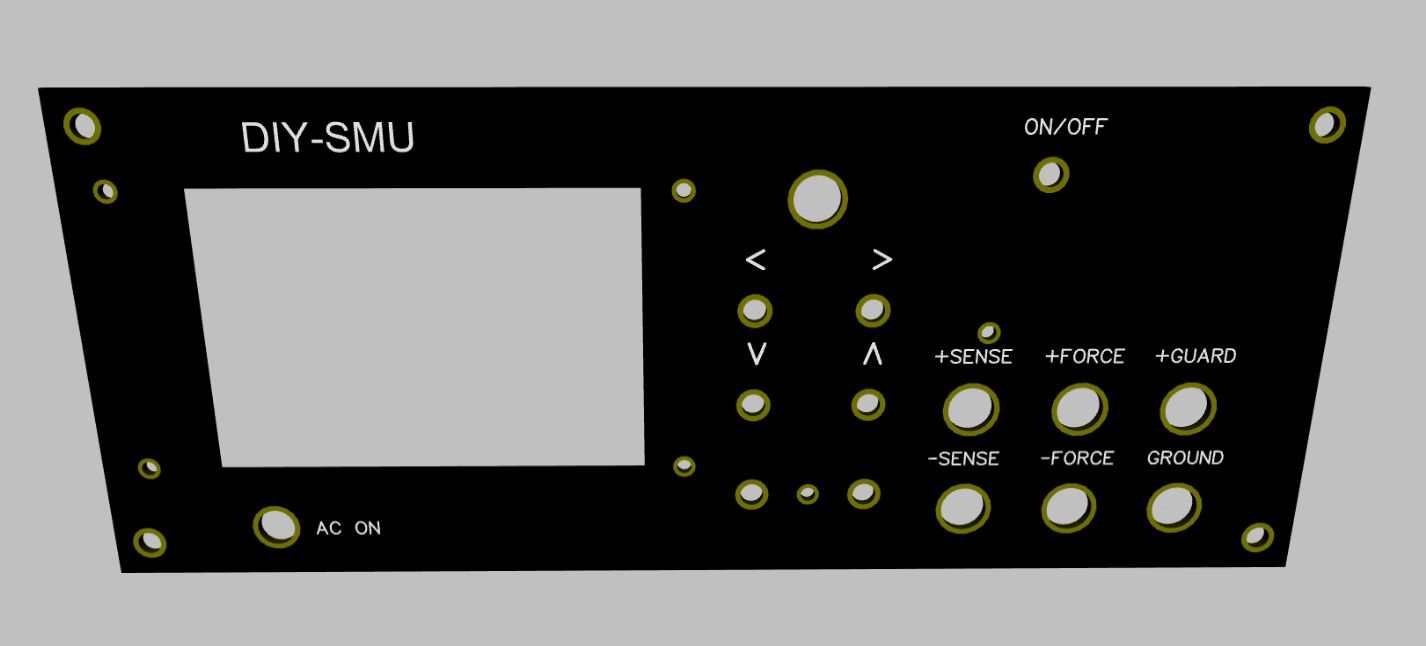

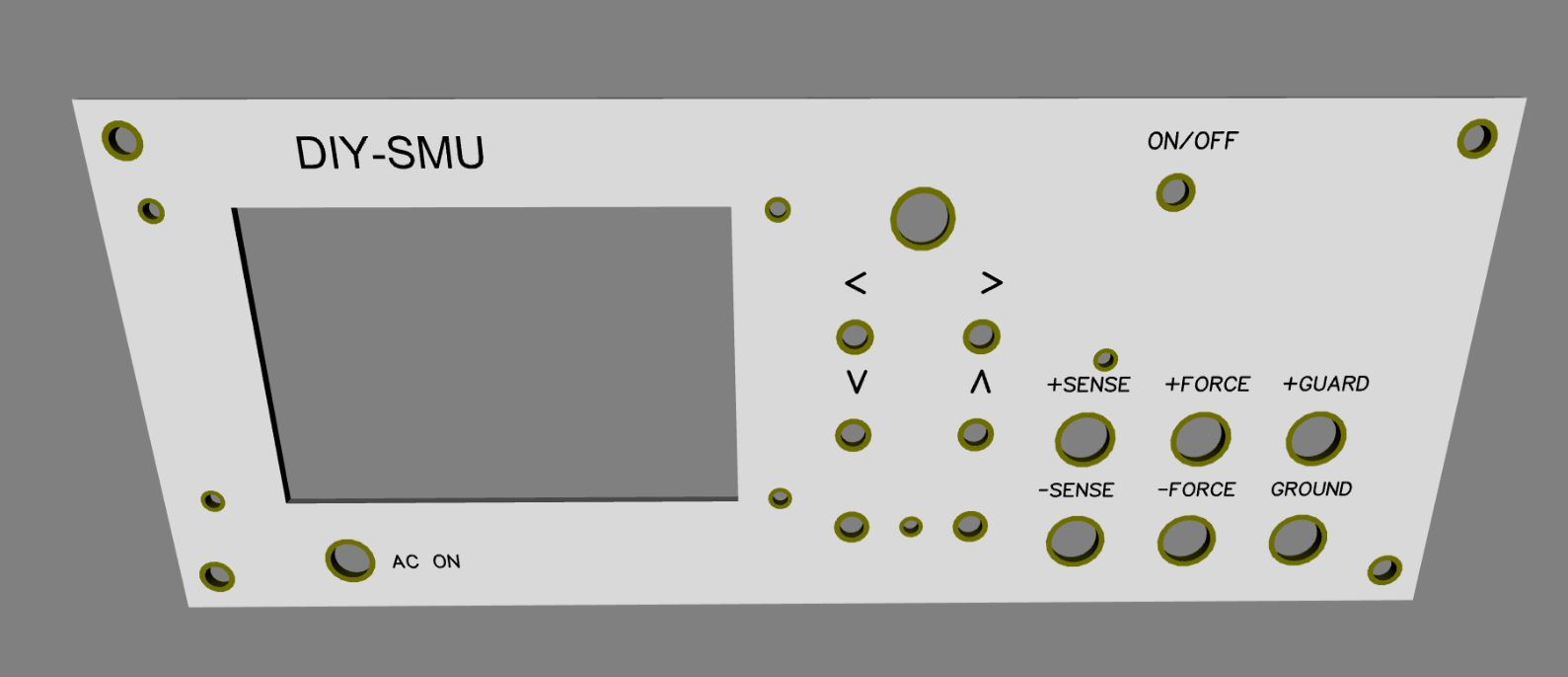

Above is the hand-made prototype front panel. Next version will be

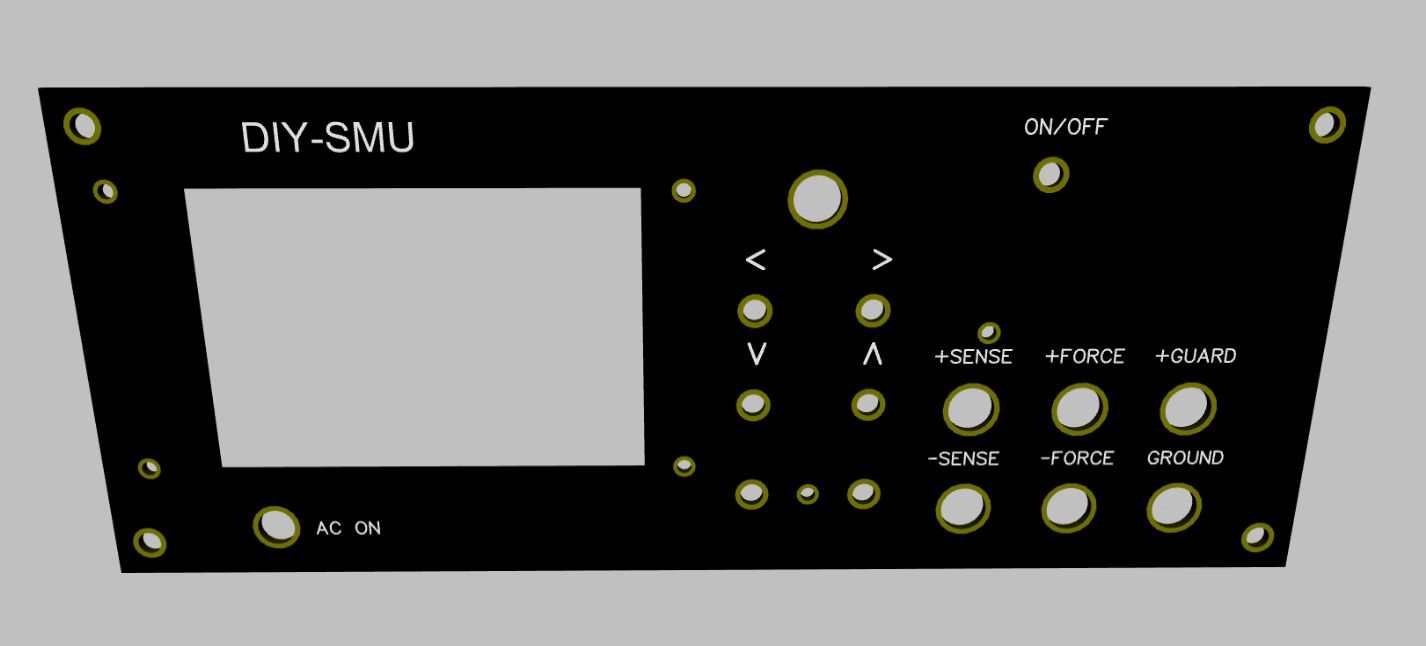

machine-built and have proper labeling. Something like this

(below). Haven't decided the colors, but am limited by the normal

soldermask and silk-screen colors: White, Black Blue, Red, Yellow,

Green. Silk screen is black or white. I plan to use larger

rectangular buttons so the buttons cutouts will be changed. And

I'll change the jack labeling from +/- to HI/LO. And add a cool

logo. Haven't yet decided what to do with the bottom 2 buttons.

Maybe Remote sense and Mode.

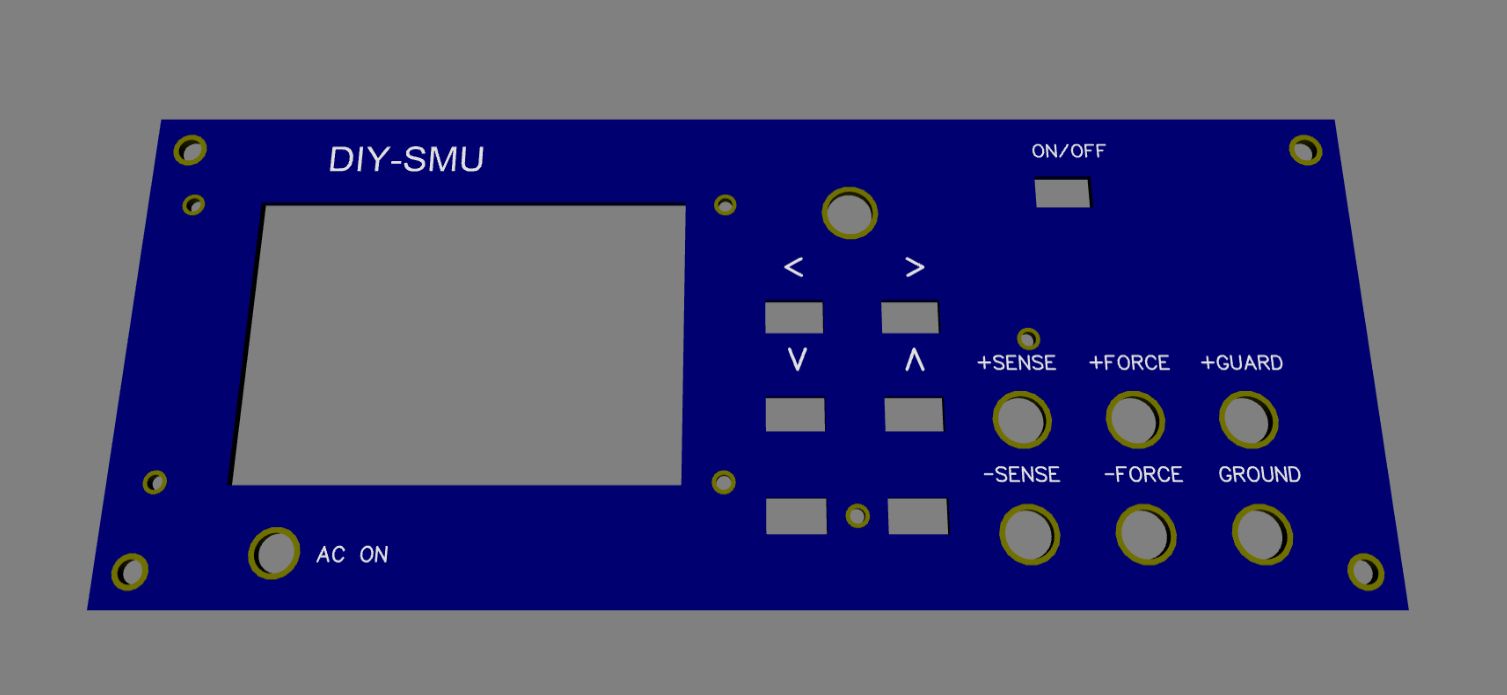

Or...

How about blue with the cool square buttons.

New Stuff: 1.5V range

and Remote Sense

I am working to add the

last few hardware functions: 1.5V voltage range and remote sense.

1.5V was fairly straightforward, consisting of a SSR (Solid state

relay) that reduces the force DAC gain by 1/10 and the software to

control it. I was concerned that the SSR would have minor leakage

and could affect the 15V and 150V ranges. I tried heating up the

SSR and no change in 15V. The fact that a 60V switch is only

switching +/- 5V helps keep leakage low.

Next is the remote sense relay. I installed the relay and created

a function to control it. It works fine as long as the remote

sense terminals are connected to the source. But as I suspected,

when the sense leads are disconnected, the sense inputs float, and

so the sense voltage is off by as much as several (10 or more)

volts. The usual way to address this is to have a high-value (like

100K) resistors from the local sense to the output. But should the

resistor sense the output before the output relay or after? Hmmmm.

As long as the firmware always sets remote sense to LOCAL when the

Output relay is OFF, it shouldn't matter. The problem is when

remote sense is REMOTE and the output relay is OFF. For this

rev board, I'll just be careful to keep the remote sense LOCAL.

And will add the resistors to the Rev2 artwork.

I see that the K236 does not have these high-value resistors. Not

sure why not, since it seems much safer to include them. It seems

easy to have a remote sense lead(s) disconnect somewhere, then

your voltage / current source is running semi-open-loop. Maybe

it's because the K236 uses Triaxial connectors, so it's hard to

disconnect the Sense without disconnecting the Force. Much easier

to make the mistake with banana jacks.

The downside of using 100K local sense resistors is that they

cause a remote-sense voltage error by the ratio of the two local

sense resistors (100K (Rls) and the 2 remote sense wire

resistances (Rw). And the voltage drop in the Force wires and

force relay (Vd). The error is ~ 2 * Vd * Rw / Rls. With 200mV

drop in the wires and 1 ohm (kind-of high) remote sense wires, the

error is ~2 * 0.100V * 1ohm / 100K = 2.0 uV. Not bad at all. Hey

this is a DIY project: if you hate the 100K's, just un-solder

them. Or use <<1 ohm sense wires.

Problem: Voltage clamp

in the presence of an external voltage

With FVMI, the clamp is a

current. This is a fairly safe mode since the current is always

limited by the current clamp, no matter what the voltage. But

there is a problem with FIMV. Voltage clamps cause the

voltage to be hard limited. But if you allow clamping of voltage

and apply an external voltage that is outside the clamp range, the

current can get very high, limited by the coarse current limiter

on the amplifier board, about 150mA. The old irresistible force /

immovable object problem. This protects the amplifier, but not the

more delicate current shunts and current range switching. I fried

at least one 10mA (499 ohm 1/2W) current shunt and its CMOS

switch. I'm trying to understand the problem better and to come up

with a solution.

I ran the Spice simulation of FIMV mode, set current force to

10mA, set the voltage clamps for +/- 15V, and tied a 22V source to

the output. The simulation won't stabilize (a bad sign) unless I

put a 100 ohm-ish resistor in series with the 22V load. On the

10mA range, sure enough, the current increases to 33mA or higher.

High enough to cook the 499 ohm current shunt as well as the DG441

CMOS switch. Then (in the middle of the night) I remembered that

the Keithley 236 has FET switches to control the amplifier's local

current limit. There is a high range and a low range. The high

range is for > 100mA and the low range limit is about 15mA, a

safe maximum current for the 10mA and lower ranges. Another "Oh,

THAT's what that circuit is for!" moment. I will add this to the

next revision Amp board. It requires a 5V control signal that goes

HI for the High current range (100mA). The existing 100mA range

control bit is LO for the 100mA range so I either need an inverter

or another control bit. There are 3 free bits and a spare pin on

the Amp drive connector J2 on the main board.

Problem: Step-response

Overshoot!

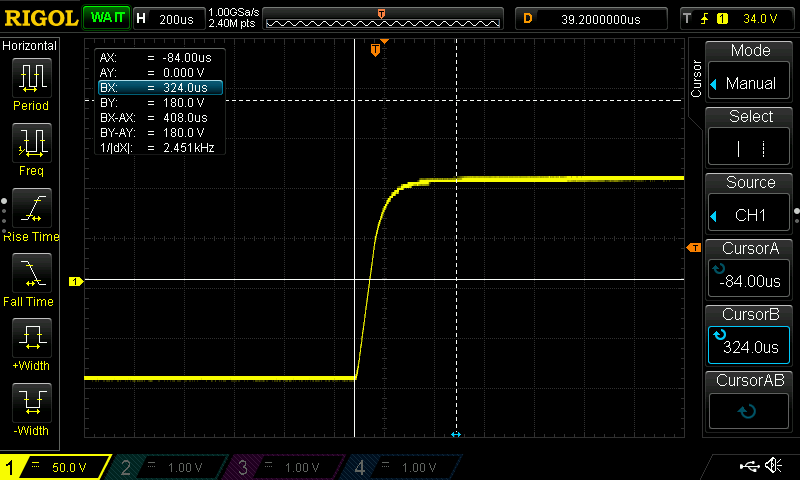

Another engineer,

Jaromir, also built an SMU, based on the K236 with inputs from my

design. He noticed that with voltage steps, there was about 10%

overshoot, followed by a short settling time. I Let him know that

my unit exhibited a nice well-damped step response: exponential,

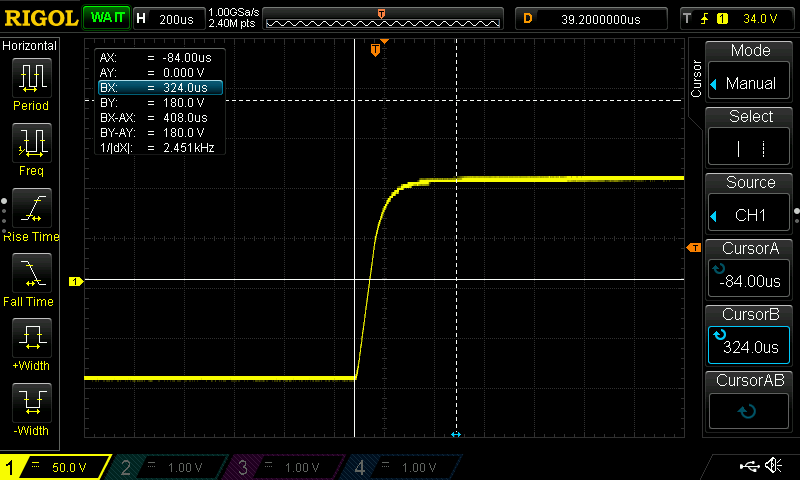

with no overshoot. Here is a 200V step response. No overshoot, but

perhaps a bit slow, about 400uS to settle.

I had 2 systems, and had not tested the step response on Board #2.

When I tested it, I saw similar response to what Jaromir reported.

Hmmm. I compared the two boards carefully, even removing some

components to measure them accurately. There were a handful of

differences between the two boards. Board #1 had been used to

debug many initial problems, and some of these changes hadn't been

put back.

- Force DAC filter

capacitors. No difference.

- Integrator P term

resistor R27: #1 had 1K, #2 had 2K. Changed, no difference.

- Checked most of the

compensation caps: no difference.

- Checked value of Y

capacitor C5, #1 had none. No difference.

- There was no C34 on

#1, no difference.

- #1 had no output

relay installed. I installed it and no difference.

- I installed #2 in

the enclosure, so the power CPU and mostly, the Amplifier

Board were different. It still had overshoot.

Finally after

implementing all the changes, I re-tested #2 and the overshoot was

fixed.

LVGL?

I started messing with

the new graphics library, LVGL. While I wait for 3.5" 480 x 320

panels to arrive from Asia, I started learning LVGL. First I went

to LVGL Academy. The first

intro video courses are free, and the full course costs $25; well

worth it. Then I installed the LVGL simulator, based on Visual C.

There are other versions available for Eclipse and other IDEs. The

simulator requires Visual Studio Community 2019. I haven't tried

it on the newer Visual Studio Code yet. Then install Python, then

install the simulator. Then the examples run. They pop-up an LCD

display window which responds to mouse commands. It's all new, and

I'm just beginning. Of course everything is completely different

from Nextion. To start with I'm trying to set up a display similar

the Nextion one: A few numeric and alphanumeric test displays, in

small and large fonts, color fonts, and some type of cursor.

I was able to get the NXP editor working. It is the first

drag-and-drop editor for LGVL. It is set up for NXP processors and

boards, but it generates generic C code.

I also bought a board with a Teensy and 3.5" LCD. Turns out it

also does NMEA2000, the boat data standard based on CAN bus. But I

cannot seem to get their examples to compile. Worse, I can't get

the LVGL libraries working.

Vini from OSMU helped me get the STM32F746 Discovery kit working.

It is not Arduino, but runs LVGL nicely on the STM32Cube tool set.

One key feature I have used on several projects since my character

LCD days is unfortunately not available in these fancy Graphics

libraries: a simple underline cursor. Or a block cursor. I use

this to set individual digits of a number. This is particularly

useful with 5 or more digit numbers. With an old character LCD,

it's just there. With OLEDs, I had to calculate the position of

the characters and put a line underneath the right character. Same

with Nextion. But the SMU has many values to set, and many are

range-dependent. The simple Cursor code gets ugly fast. LVGL has a

widget that is close, their Spin Box. But unfortunately its cursor

is a bit cumbersome, and I see no way to get rid of the clunky +

and - controls.

I decided that LVGL isn't ready for us mere mortals yet. I'll

continue using Nextion.

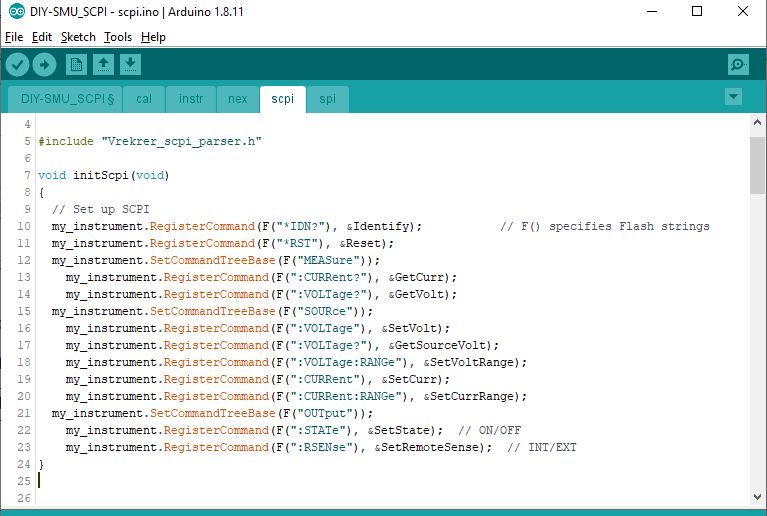

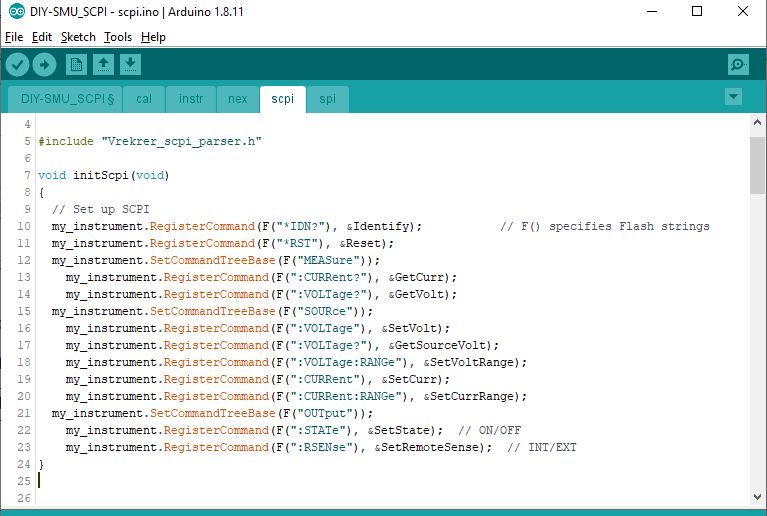

SCPI Control

For SCPI I found 3

libraries: 2 are Arduino Libraries: https://github.com/LachlanGunn/oic

and https://github.com/Vrekrer/Vrekrer_scpi_parser.

Vini from the OSMU project has been helping me. He pointed

me to the full-featured SCPI library: https://www.jaybee.cz/scpi-parser.

One of OIC's examples implements a simple Source-Measure unit

using Arduino ADC and PWM pins. This is a perfect example. I

tested the parser code by sending various number formats for the

voltage settings: Integer, fixed point, and scientific notation.

They all work well, which is wonderful. Now I'm changing the

example to implement ranging, current measure, etc. Nice

job, LachlanGunn! I'll try out the Jaybee parser as well.

Vini is helping to get SCPI working on the SMU. But meanwhile, I

want to get experience with SCPI, and also want to implement it on

older and future projects. I began with the OIC library. I got it

working on a Teensy, and was happy with how quickly it came up. My

18b DAC project was crying for a proper way to control it via USB.

And it is a simple enough project: *IDN?, *RST, set and get the

DAC to a voltage, done!. See the 18b

DAC project for details. I tried to install all 3 libraries.

OIC and Vrekrer worked well. Jaybee is much larger, with 8 .c

files and 10 .h files. I could not get it to compile on Teensy. I

settled on the Vrekrer library. It is simple to use and works

well.

My next step was to use the 18b DAC as a test platform for

additional SCPI commands. This worked out well without the

complexity of all the SMU code.

Adding this library to SMU on Teensy went fairly smoothly. I found

that I needed to control the SMU data structure variables, set the

hardware, and update the display. This forced me to refactor

several additional control functions such as setOnOff(). It's all

good. Here's the first pass SMU SCPI command list, containing the

major settings.

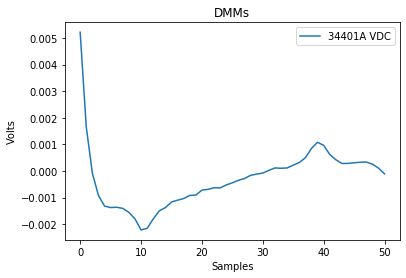

Measurements and error

plotting: ADC errors

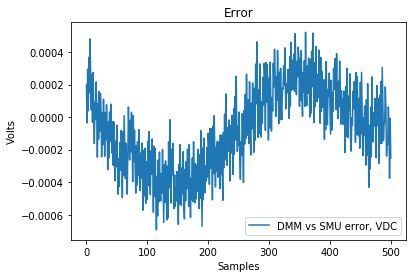

As rewarding as it is to

type in SCPI commands and see them execute, it is far more

exciting to write a program to control instruments via SCPI. For a

control program, I am currently using Python Spyder and pyvisa.

For the first time I can automatically sequence through a voltage

or current range and compare the output of the SMU to my 6.5 digit

DMM.

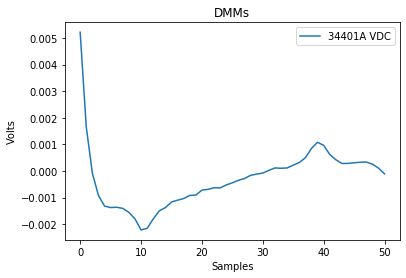

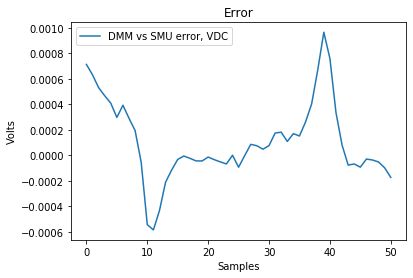

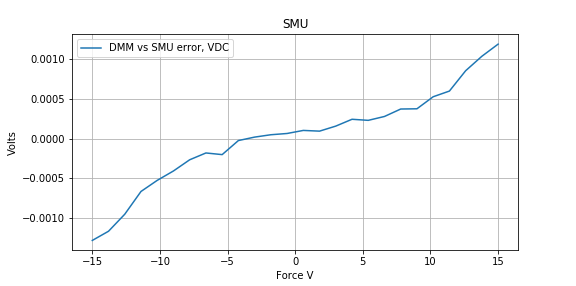

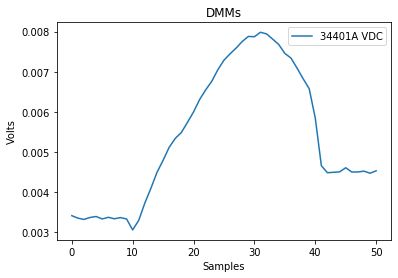

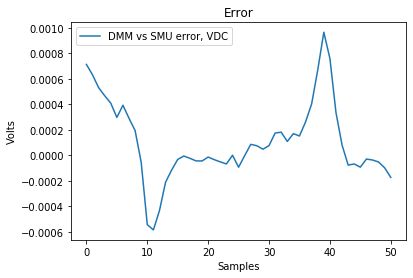

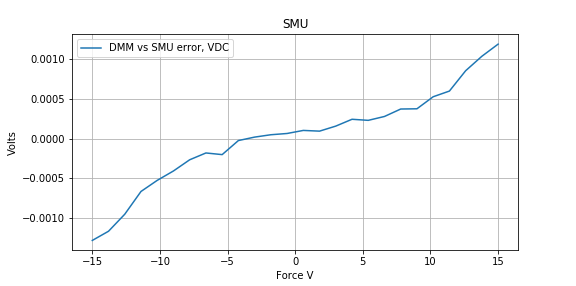

This first Python plot compares SMU Measure to the DMM over a -15V

to +15V voltage range set by the SMU and shows the error. Note the

mirror-image bumps around -9V and +9V. The rise at -15V is another

error. Is it the voltage measure circuit, the ADC, maybe my DMM? I

suspected the ADC input op-amp U4, a TLC2272A. The large rise on

the left is the op-amp output near VCC, something else to look out

for.

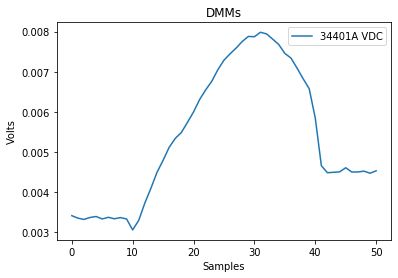

I changed U4 to an MCP6072, another mid-precise 5V RRIO part I

have used in the past. The ~6mV offset error is because it is not

re-calibrated. Completely different error shape! Similar dip at

-9V though.

This argues that the gross error shape is the non-linearity of

amplifier U4, and not the ADC or the DMM. The results are very

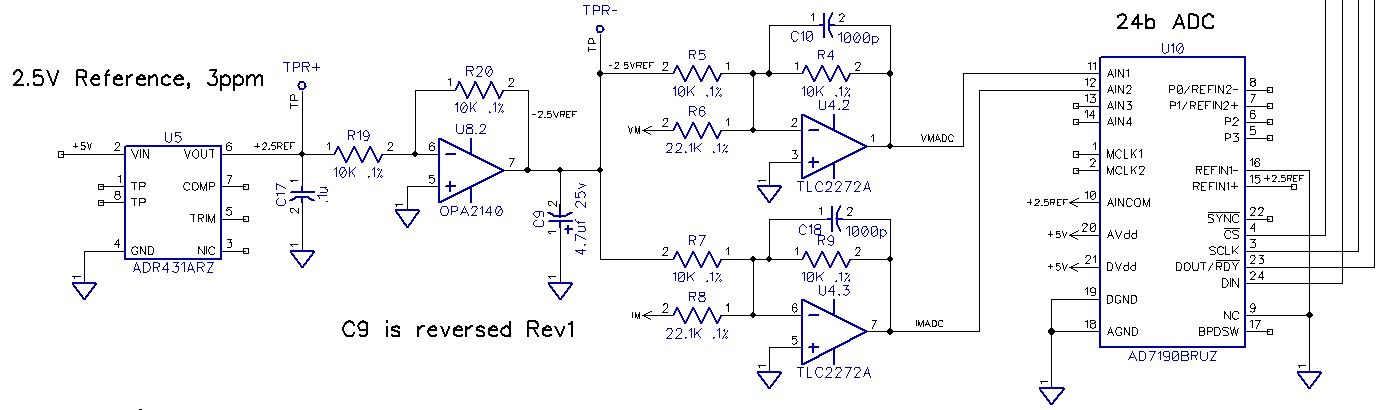

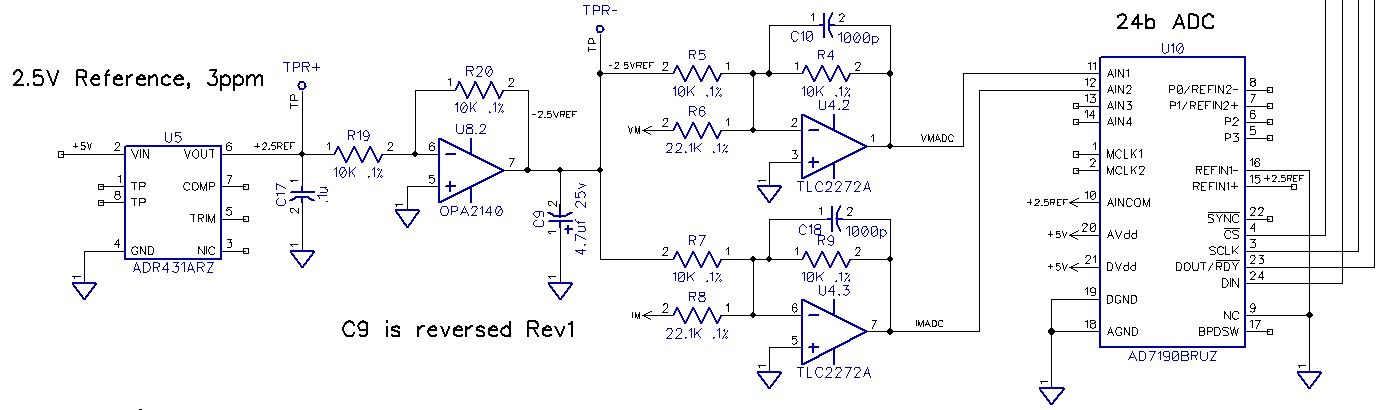

interesting. I purposely use an inverting amplifier for U4 in a

current-summing configuration to minimize any non-linearity caused

by input common-mode variation, a problem with many RRIO

amplifiers. The amplifier + input is GND, and the output is biased

to mid-scale by a very precise reference. This amplifier is

operating at a gain of 0.55: +/- 5.5V input range, 0 to 5V output.

It looks as though the op-amp input error varies as a function of

the output voltage. Something that no op-amp specifies! Over a 30V

range (+/- 15V) a 5mV error is +/- 0.008%: significant but not

terrible. Here is the schematic for the ADC input buffer, U4. U4

is powered from +5V and GND. I will try some other op-amps.

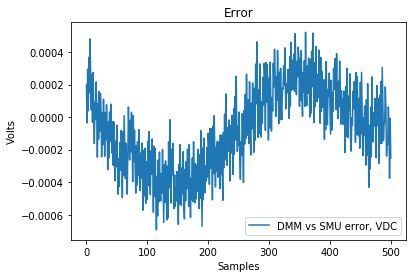

By the way, here is the Force error, effectively the DAC and

system INL, 500 samples, over a -15V to +15V range This is about

1mV p-p or +/- 0.5mV. The force DAC is bipolar 16b, the ADC is

about 23b. So the 5mV ADC error is concerning. The ADC error

should be should be < 0.1x of the DAC, not 5x worse than the

DAC. I plan to use the Measure ADC to calibrate the Force DAC. Not

until I fix the ADC errors.

Here is the new OPA3240. This is a 5V RRIO part with better input

and output specs near the rails. I re-calibrated the 15V Measure

range to correct for offset and gain (slope). This is

better, note the scale: about 1.2mV p-p. Still the mysterious

bumps at +/- 9V. Roughly 25% and 75% of the ADC input range of 0

to 5.0V. Hmmmm.

I tried turning the AD7190 ADC input buffer ON. It has been OFF

until now. With the buffer ON, the ADC loses about 0.25V of input

range near each rail. No difference was measured since my circuit

does not go that close to the rails. So it's not a ADC

buffer-related issue. Next I'll try some chopper amps,

OPA2333. OPA2333s arrived, I soldered one in. No change. The

two peaks are still there, and about the same amplitude. That's

the 4th opamp. It's not the opamp.

So it must be the ADC. I read the entire AD7190 data sheet and

found a few small issues, plus a hint. The INL spec is 5 ppm Max,

1ppm Typ. And the INL graph shows a suspicious similarity to

my error plot, but at 1ppm, not 30ppm. The other 2 small issues:

- They recommend input

RC filters for common and normal mode to remove noise that is

near the internal sampling rate. I doubt this is it. Also this

is a note only, no schematic!

- Also improved

bypassing: short leads and separate Dvdd and Avdd.

I added a 0.1uF cap

from power pins 19-18 and 20-21. Slight change in gain, but the

+/- 0.5mV errors persist.

Added a 0.1 cap to the

Ref+ pin. The data sheet warns that the reference input is

dynamic, meaning it draws AC current. This shifted the peaks

from +/- 9V to about +/- 12V. Same amplitude though. This could

be a clue!

I tried some other ADC

settings:

- Chop mode. This

reduces small offset values and offset drift bus slows

conversion time 3-4x. No difference

- Filter select: This

trades off settling time vs conversion time. No difference

- Buffer: Worse with

buffer off, depends on op-amp driving.

- Convert time: Tried

longer and shorter settings, no difference.

I looked at the designs

of two eval boards for the similar AD7193. There is no AD7190

eval board, but AD7193 is the same ADC core and specs and a 8:1

mux. Nothing in the layout jumped out at me. However both boards

have a 10uF tantalum on the reference. I have a 0.1 uF only, per

the recommendation of the ADR431. When I paralleled a 10uF

ceramic cap, the evil error curve that I have been waking up in

the night thinking about for 2 weeks WENT AWAY! The AD7190 does

not call for specific bypassing on the reference input. Finally,

noise and error in the +/- 100uV p-p range out of 30V p-p.

that's 4ppm. Love it.

There is (as always) a side effect to this change. The ADR431

reference doesn't like large capacitive loads, which cause

high-frequency peaking (see data sheet) unless additional

compensation components are added. I will switch to the ADR421

which doesn't have this issue and also is lower noise: 1.7uV vs

3uV.

I implemented the ADC

and reference reworks to unit #2. It still has an ADC

non-linearity that is slightly different than than unit 1. There

is also a gain error that will reduce after calibration. But

there is still a symmetrical error curve of about +/- 0.4mV on

the 15V range. Since this is holding up the calibration process

(below), I will defer the final linearity correction to the next

PCB revision, and move on. Calibrating over the range of +/-

11.0V eliminates most of the non-linearity errors. Also the

34401A DMM voltage ranges are only up to +/- 12V. Scandal!

34401A really isn't 6.5 digits, which generally means 19.999V,

it's more like 6.2 digits (1,2000,000 counts). BTW, the HP 3478A

sold as a 5.5 digit meter is actually 300,000 counts so for

measuring 12V to 30V, it has the same resolution as the

34401A. By using +/- 11V, the 34401A does not

auto-range, which saves both measurement time and relay

operations.

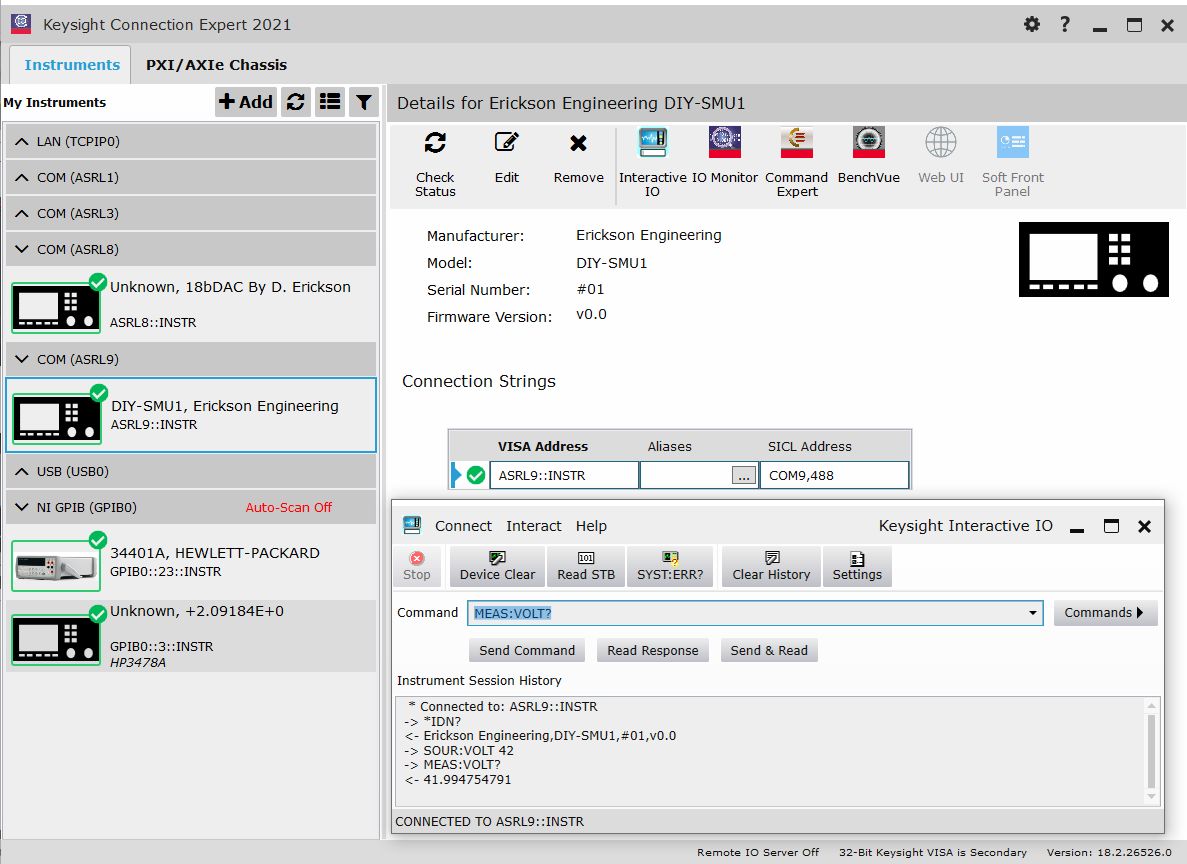

SCPI Instrument

Program

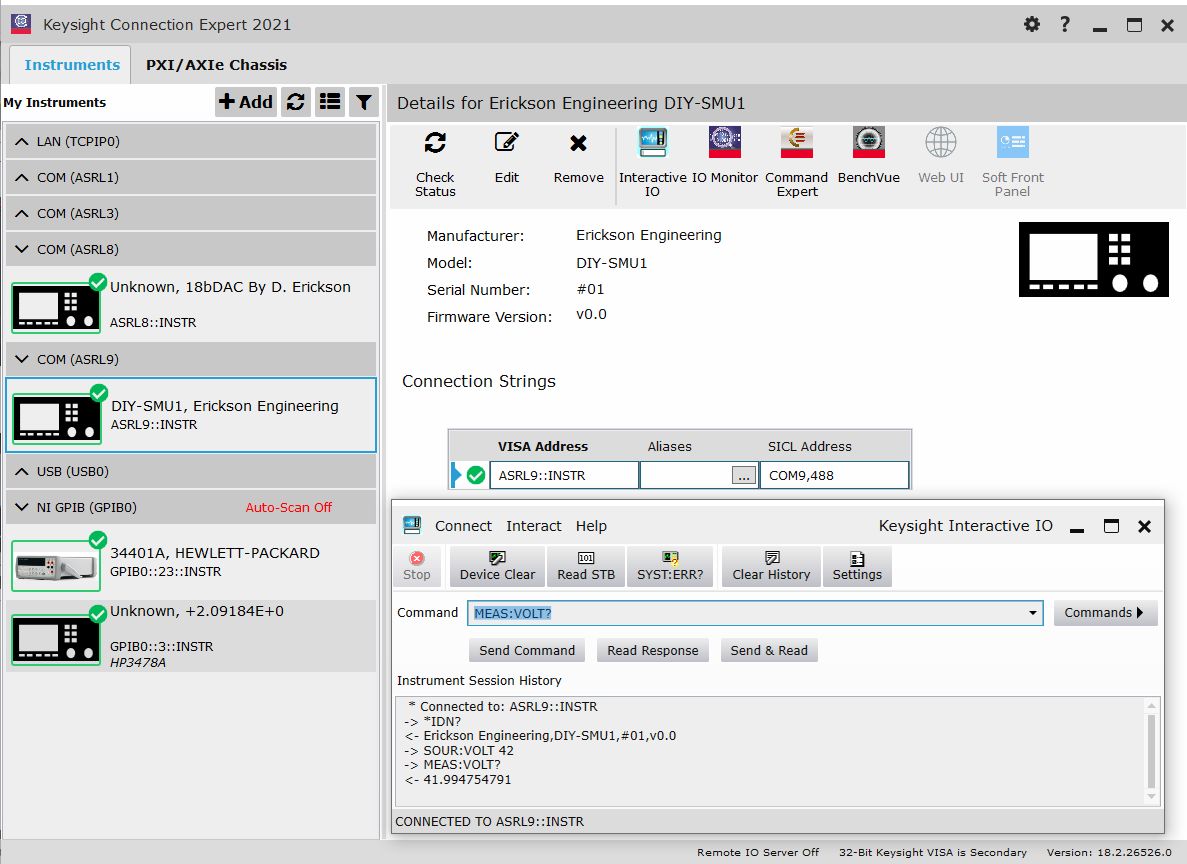

For a SCPI instrument

connection program, I use Keysight's Connection Expert. It

requires you to register and install 1-2 other programs. Here it

is controlling DIY-SMU, my 18b DAC and two HP GPIB instruments.

Very Low Source

Currents

To measure the lowest 1uA

full-scale force current range, I have been using a 1Meg precision

resistor, or the 1M/10Meg input of my scope and DMM. I have access

to a Keithley 610C Electrometer which measures extremely low

currents. The 610C lowest current range is 1e-11 x 0.001 or 10fA

full scale! Not sure what I can use to test this. It certainly

needs a shielded and guarded enclosure. Measuring SMU, it was

rewarding to see this meter stepping through 1LSB changes of the

Force DAC (~30pA) on the 1uA range.

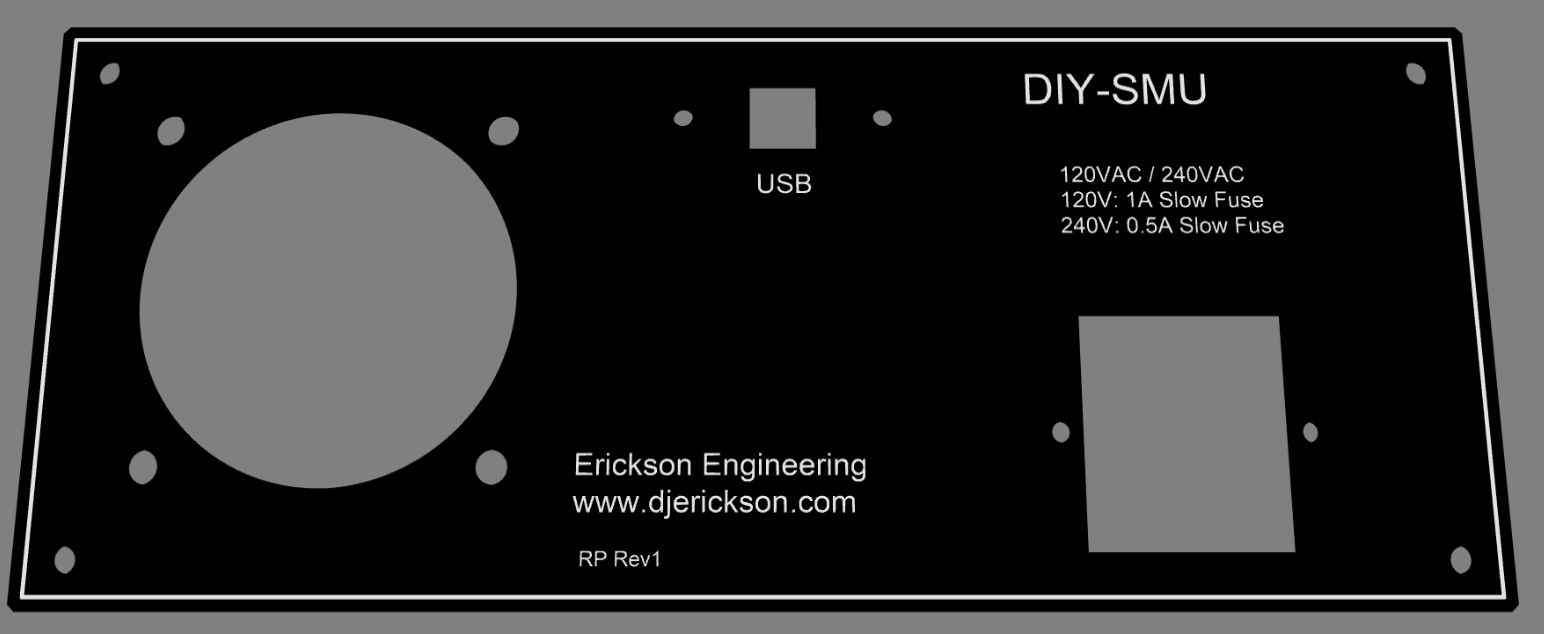

New Front panel and

Case

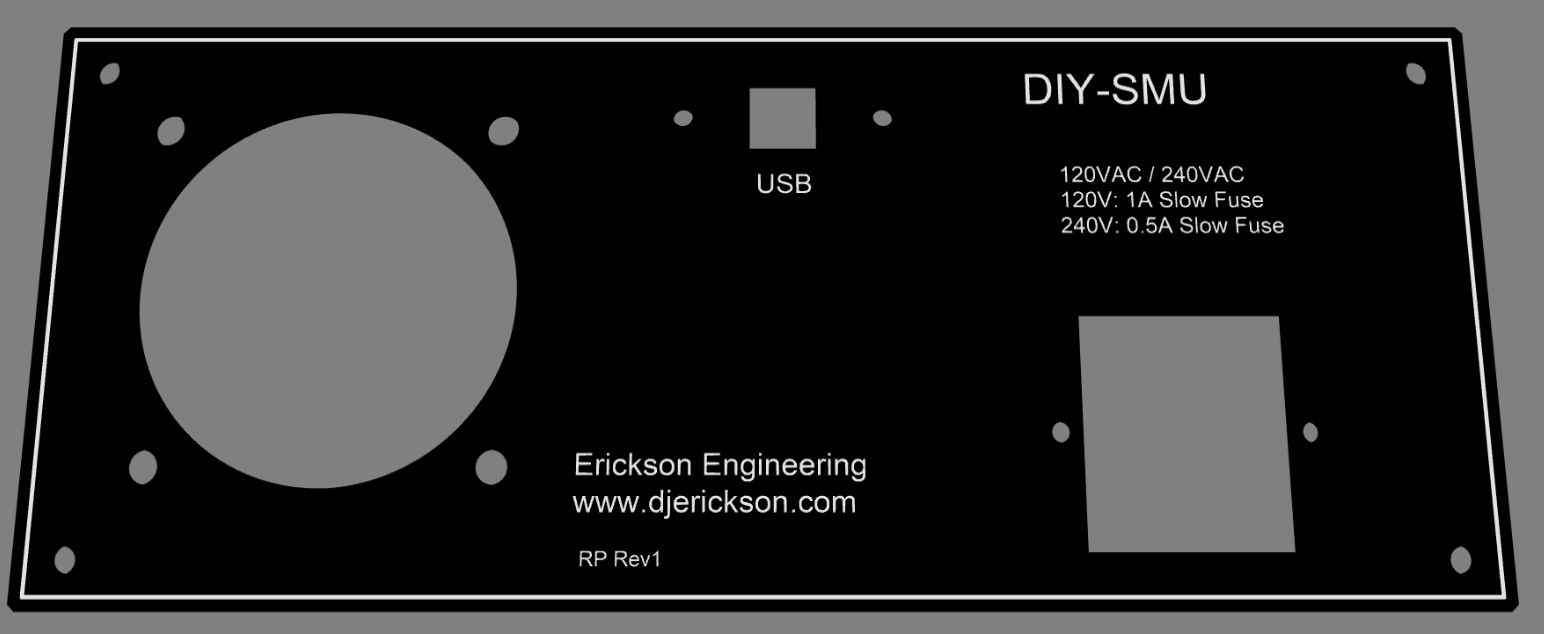

Here is the new front

panel mock-up. The panels were ordered from PCBWay, 5 for $50. I

moved the mounting rails in 1mm to better accommodate the cover

and bottom sheet metal. A one-piece, 3-sided cover is in process

as is a PCBWay rear panel. Each factory panel saves me hours of

hand sheet metal work. Let me know what you think of the

color. The cover will probably be light grey or greige.

Here is the new rear panel CAD model. Parts are on order.

The new rear panels arrived from PCBWay. They look and work great,

just like the CAD model. What a joy it is to just screw in the

components: no measuring, marking, sawing, drilling, hole-sawing,

filing, de-burring, sanding, priming and painting. No blank

panels or crummy stick-on labels. Next task is to convert

the lower unit to the new chassis and panels.

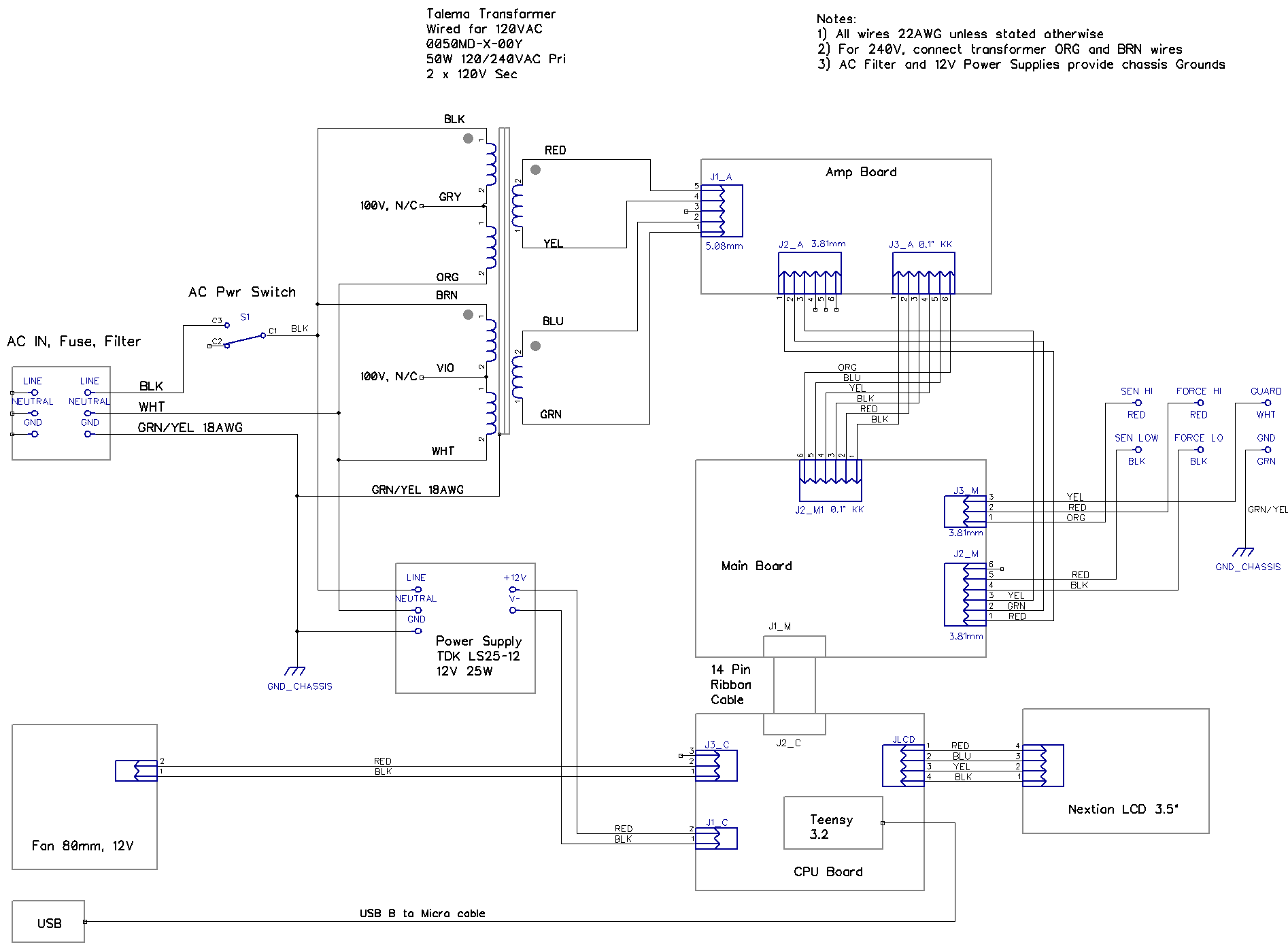

Chassis Wiring

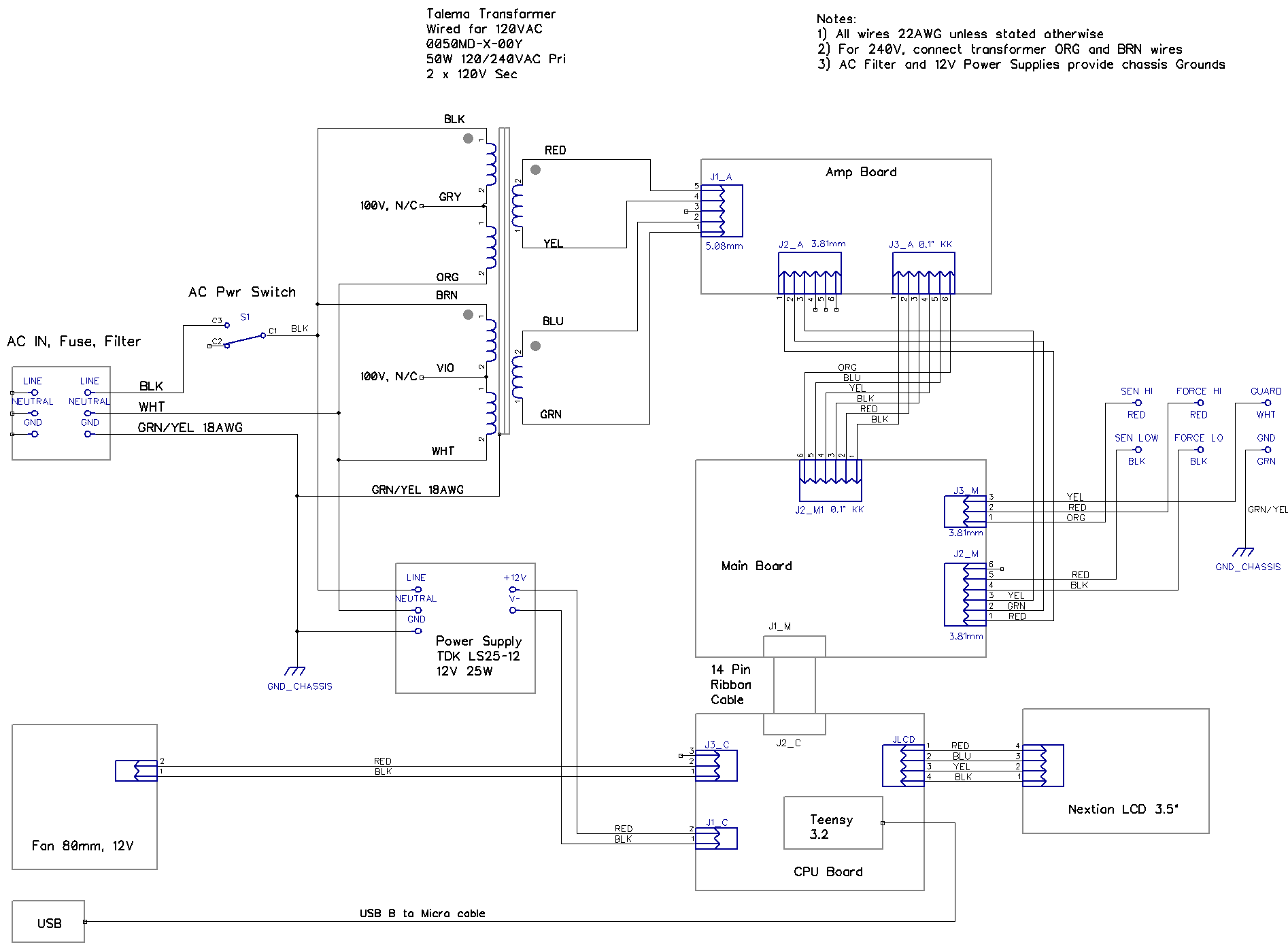

It occurred to me that I

have all the chassis interconnect details in my head, and that

anyone building a DIY-SMU would benefit form a wiring schematic,

showing the chassis components, AC and DC wiring, and cables.Here

is the schematic.

Calibration Update

I have been working on

a new calibration method. Now that SCPI is working, it makes

sense to calibrate using an external program and external

instruments. I mentioned before the method I have been using to

calibrate

manually. I set

the force to 0V, and get a Force offset cal correction, entering

the value into the code and re-compiling, then repeating for

Force gain. Then repeating the process for both Force and

Measure on 3 voltage and 6 current ranges. Not pretty or fun,

not to mention error-prone. While testing the Force and Measure

linearity with Python, I found that taking a series of

measurements and then doing a least-squares linear fit on the

error data works very well. I use the Python np.polyfit()

function to provide offset and gain cal factors

simultaneously. The Python program generates cal factors

for each voltage range. I needed a way to pass the cal factors

to the SMU via SCPI. I chose CALibrate:VOLTage index, value to

send one single-precision, floating point cal factor at a time.

The index will use 0,1,2,3 for FVGain, FVOffs, MVGain, MVOffs

for the 1.5V range, then proceed through the other voltage and

then the current ranges. Values will be sent to RAM first, then

copied to EEPROM. Another SCPI command disables or enables

calibration: CAL:STATe ON/OFF. I also need a way to identify a

blank EEPROM and not load cal from it.

Next is Calibration of

the current ranges, and commands to copy the data to EEPROM. For

current cal, the cal program prompts the operator to manually

change the load resistor for each range. I built a handful of

precision resistors on dual banana plugs for this. I also

found and fixed a few bugs with Force current setting over SCPI.

Temperature Drift

Measurement

I tested one instrument

for temperature drift of Voltage Force and Measure over a 10°C

range, from 28°C to 38°C. The overall Force and Measure drift is

primarily caused by about 10 resistors, each contributing

between 1.0 and 0.5 of their drift to instrument gain drift.

These are mostly 0805 0.1% 25ppm/°C resistors, except for the

four 0.01% 5ppm ones used in the voltage-difference

circuit. The Reference, DAC and ADC are all in the 1-3

ppm/°C range. Here is a Voltage Gain Drift analysis spreadsheet

showing the temp drift contribution of each component in each of

the Voltage Force and Measure signal paths. RMS assumes Gaussian

distribution for the drifts, and uses the square root of the sum

of the squares. I calculate about +/- 60ppm and measured

+20ppm/°C for both Force and Measure drifts.

This spreadsheet is

useful to show the largest contributors to drift. To improve

drift, 0805, 10K, 10ppm resistors are available for about $.50.

Other value 10ppm resistors are about $1.00. 5ppm 10K's are

about $1.30 and other 5ppm values are about $2. The crossover

uses two connected 10K's which could be a SOT23 network to

reduce its drift to ~1ppm.

Here is my DIY bench-top temperature setup. The top box is a

small oven I built to test boards and components. The chamber

bottom is open to allow it to be placed over an experiment. The

bottom cardboard box is an adapter to allow the too-large

DIY-SMU to fit.

10/20/21 Updates:

Calibration Code

I completed the

calibration Python code and am happy with it. The voltage

calibration calibrates all 3 voltage ranges for force and

measure in one step. The current calibration requires changing

the load resistors for each current range. I created a simple

menu to select the current range and prompt the user to install

the correct resistor.

- 1uA: 1

Meg-ohm, 1V

- 10uA: 1 Meg-ohm, 10V

- 100uA: 100K, 10V

- 1mA:

10K, 10V

- 10mA: 1K, 10V

- 100mA: 10 ohms, 1V

My HP34401A Ebay meter

hasn't been calibrated in a few years. I'll get it calibrated in

order to get accurate resistance values for my cal resistors.

I still don't write the calibration values into EEPROM. The

calibration python code generates C code for the cal factors,

which you copy into the cal.ino file. Then you recompile the code

and go. This means that you need to manually select which cal.ino

gets used for a given unit. Here is typical voltage cal data

generated by the Python code. Note that the offsets are in the

tens of millivolts range and the gains are all within about

2%. If the cal values are out of whack, it means there is

something wrong with the hardware. I should add a limit test.

// Calibrated at 2021-09-17 11:06:22.578853

// 1.5 V Range Cal

Range[VRange_1_5].FGainCal = 0.98599201 ;

Range[VRange_1_5].FOffsCal = 0.00000794 ;

Range[VRange_1_5].MGainCal = 1.00229606 ;

Range[VRange_1_5].MOffsCal = -0.00187238 ;

// 15 V Range Cal

Range[VRange_15 ].FGainCal = 0.99274970 ;

Range[VRange_15 ].FOffsCal = -0.00155500 ;

Range[VRange_15 ].MGainCal = 1.00230964 ;

Range[VRange_15 ].MOffsCal = -0.00187619 ;

// 150 V Range Cal

Range[VRange_150].FGainCal = 1.01223362 ;

Range[VRange_150].FOffsCal = -0.01591642 ;

Range[VRange_150].MGainCal = 0.98301726 ;

Range[VRange_150].MOffsCal = -0.01869274 ;

Page 1: the Analog part

Page 2: the Digital part

Page 3: Board

Bringup 1

Page 5: Board Bringup 3

Dave's

Home Page

Last Updated: 3/7/2023