PS-Load Page

Power Supply / Load or

2/4 quadrant voltage current source / meter

Arduino-based Power Supply / Load

The Schematics, PCB files,

and Simulation models are here

Here is the DIY-SMU

project

As an EE, I have designed, used and messed with power

supplies for much of my life. My Power-One blog attests to this.

As part of this work I have built a number of load circuits from

arrays of power resistors to a simple electronic load, to a

combined power supply and load circuit. As Keithley and Hewlett

Packard and others long ago discovered, a combined power supply

and load has some advantages. It combines the functions of a power

supply, an electronic load, a voltmeter, and a current meter. As a

result it can fully test batteries, solar panels, power supplies,

or any power source. When testing batteries, it can charge or

discharge using any type of charge cycles. So it is great for

battery research and testing. It can either test or simulate a

battery. It can test high power LEDs, or other semiconductor

devices, and provide V-I curves, similar to a semiconductor curve

tracer. An when not providing these advanced functions, can be

used as just another lab power supply.

As an EE, I have designed, used and messed with power

supplies for much of my life. My Power-One blog attests to this.

As part of this work I have built a number of load circuits from

arrays of power resistors to a simple electronic load, to a

combined power supply and load circuit. As Keithley and Hewlett

Packard and others long ago discovered, a combined power supply

and load has some advantages. It combines the functions of a power

supply, an electronic load, a voltmeter, and a current meter. As a

result it can fully test batteries, solar panels, power supplies,

or any power source. When testing batteries, it can charge or

discharge using any type of charge cycles. So it is great for

battery research and testing. It can either test or simulate a

battery. It can test high power LEDs, or other semiconductor

devices, and provide V-I curves, similar to a semiconductor curve

tracer. An when not providing these advanced functions, can be

used as just another lab power supply.

What is the difference between a source-meter and a lab Power

Supply? Both can source current and voltage, and measure current

and voltage, making them one quadrant devices. The difference is

that generally a source-meter is a four quadrant device. I will

show that a 2 quadrant device that contains a positive source or

load can be a useful configuration. The number of

"quadrants" refers to the polarity of the output voltages and

currents, as shown in this diagram.

But only a few power specialized power supplies can sink current.

the HP6632A and its siblings are examples of power supplies that

can provide a load. Seems like a useful thing to have.

Particularly since it only costs a few extra components and a bit

more control circuitry over a simple power supply.

To generate a negative power supply, one typically connects a

positive supply in reverse, with its + terminal to common (ground)

Then it is still a one quadrant device, but a different quadrant.

A source-meter can typically provide both + or - voltages, and can

source or sink (+ or -) current while providing either polarity

voltage. They are therefore 4 quadrant devices. A source-meter

that can only do positive voltage but can source and sink current

is a 'two quadrant' device. For testing semiconductor

devices, four quadrants is almost a necessity. However, there are

advantages to 2 quadrant devices which I discuss below.

A few years back, I built a simple 2 quadrant VI which is

described in the Power One page. I have used this to test high

power LEDs and batteries. However, this circuit has some

limitations. For one, it did not have front panel controls, so it

always requires a PC to control it. If the PC crashes or the power

goes out during your battery test, you lose data and worse, can

over-charge or discharge the battery, causing damage and possibly

a fire. Also most power supplies are not designed to drive a

battery. If you inadvertently power the supply down, the supply

may be damaged by having a high-current voltage on it's output. It

is important that any battery teste power down gracefully if the

AC is removed.

Keithley source-meters are fine precision devices with multiple

current ranges allowing them to source and measure currents from

Amps down to microcroamps, and below. They use 5 digit meter

circuits, and are generally four quadrant devices. As a result,

you pay for these capabilities, typically $4000 for a single

channel 2400 unit. If you need to test multiple batteries

simultaneously, which is often the case as it takes a long

time to charge or discharge a battery, this gets expensive fast.

For a programmable lab power supply, ADC and DACs are needed,

current and voltage measure circuits, a series pass power element

(transistor plus heat sink). What I propose here is a combined

power supply load that is flexible and accurate enough to perform

a range of test functions, and that has the following

capabilities:

- Nominally 2

quadrant, 0 to +24V

- Optional -24V (4

quadrant)

- 0 to 3 Amp Source

- 0 to 5 Amp Sink

- Vset resolution

about 10mV

- I+ and I- set

resolution about 10mA

- Vmeasure resolution

to 1mV

- Imeasure resolution

to 1mA

- 0.1% or better

overall accuracy

- Full isolation from

ground

System and Packaging:

- Single CPU and front

panel can control 1 or up to 4 isolated channels on one I2C

bus

- Each of the 4

boards supports different I2C addresses

- Boards can use any

Arduino, Raspberry Pi, or any other CPU for control

- Multiple channels

can be packaged together

- Single shared

supply (lower cost, common ground)

- Or separate

supplies (isolated ground)

- Fan control,

variable speed

- For raw power, can

use transformer / rectifier / filter or low-cost switching

supply

For controls, an optional

Front Panel board provides:

- Arduino Leonardo

Compatibility

- 16x2 or 8x2

LCD, large or small

- 4.5 digit display

for currents and voltages

- Encoder knob for

setting voltages and currents

- LEDs for status on

each supply

- USB control from PC

- Controls and PC

isolated from power

A programmable lab supply

is one with an external interface such as GPIB or USB. It uses the

same basic power and control circuits, but instead of using

potentiometers to set voltage and current, it uses DACs, and

instead of a digital panel meter to read current and voltage, it

uses an ADC. Once a supply is programmable, adding a front-panel

consisting of a simple processor, display and controls is

straightforward. Ideally a single front panel can control and

multiple supplies with a simple menu system.

The other elements of a programmable power supply are a raw DC

supply, some low voltage DC supplies for the control circuit, a

series pass element and its thermal management (heat sink, fan),

control circuitry, a crossover capable of smoothly switching

between constant current and voltage control, a reference voltage,

and current and voltage measuring circuits. Typically there is a

turn-on circuit and status LEDs that indicate whether a channel is

on, and in constant current or voltage mode.

To make a 2 quadrant PS-Load, a second series pass element is

required. Since only one series pass element is drawing current

and therefore dissipating power at a time, it can share the heat

sink and fan with the other device. Another DAC to set the

negative current is optional. My original 2 quadrant design used a

single DAC to set the + and - currents to the same value but

opposite polarity with good successes. Some commercial products

also use this shortcut.

To make a 4 quadrant device, the raw supply provides both + and -

voltages. The advantage of 4 quadrants is that it can provide

either + or - voltage under user control. A disadvantage is that

it may be easier to fry a DUT by inadvertently applying a negative

supply. A subtle but important downside of a 4 quadrant system is

that when using it as a load, the current for the load is

generally derived from the negative supply, not the ground return.

The negative pass element therefore has the negative raw

supply voltage plus the positive load voltage across it. This

burns much more power than a normal electronic load, or a 2

quadrant device where the negative pass element is simply

grounded. So the circuit tends to be power limited instead of

current limited, and therefore cannot sink as much current.

So if you plan to use your PS-Load as a high power load such as a

battery or power supply tester, the 2 quadrant version is

preferable, and also slightly lower cost.

Output Stage

There are many output

stage designs that can be used including bipolar transistors and

FETs. Here are the general output stage requirements:

- Low impedance output

for stability into different loads

- Able to shut

off using software or hardware commands

- Able to shut off if

power is not applied: powers down to a benign condition

- Able to go to low

voltage as a load: less than 1V at full current

Emitter followers using

bipolar transistors can meet most needs except for the low voltage

requirement. FETs can achieve < .1 ohm to GND as a load.

Complimentary, common-drain MOSFETs can pull the supply very close

to the rails (low drop-out), but have a high output impedance

(essentially a current source) until they come close to

saturation. This high impedance means that the amplifier loop gain

is a strong function of both the load resistance and capacitance.

This makes it difficult to stabilize the loop for all kinds of

loads when these types of stages are used.

Complimentary Source followers have low output impedance, but

require gate drive circuits that exceed the power supplies, or

else can have up to 5V loss at high currents. I call the high

voltage supplies V++ and V-- boost supplies. These can be built

with a simple charge pump consisting of a 555 oscillator and some

diodes and capacitors. This type of stage requires that the driver

amplifier have a fairly high power supply voltage rating: the raw

supply (+/- 25V) plus about 12V extra on each supply is 74V. There

are several amplifiers that meet this need. To accommodate even

higher supply voltages or unregulated supplies, the supply

requirements are higher. Linear has a nice high-voltage opamp,

LTC6090 that accommodates up to 140VDC and costs about $3 (q100).

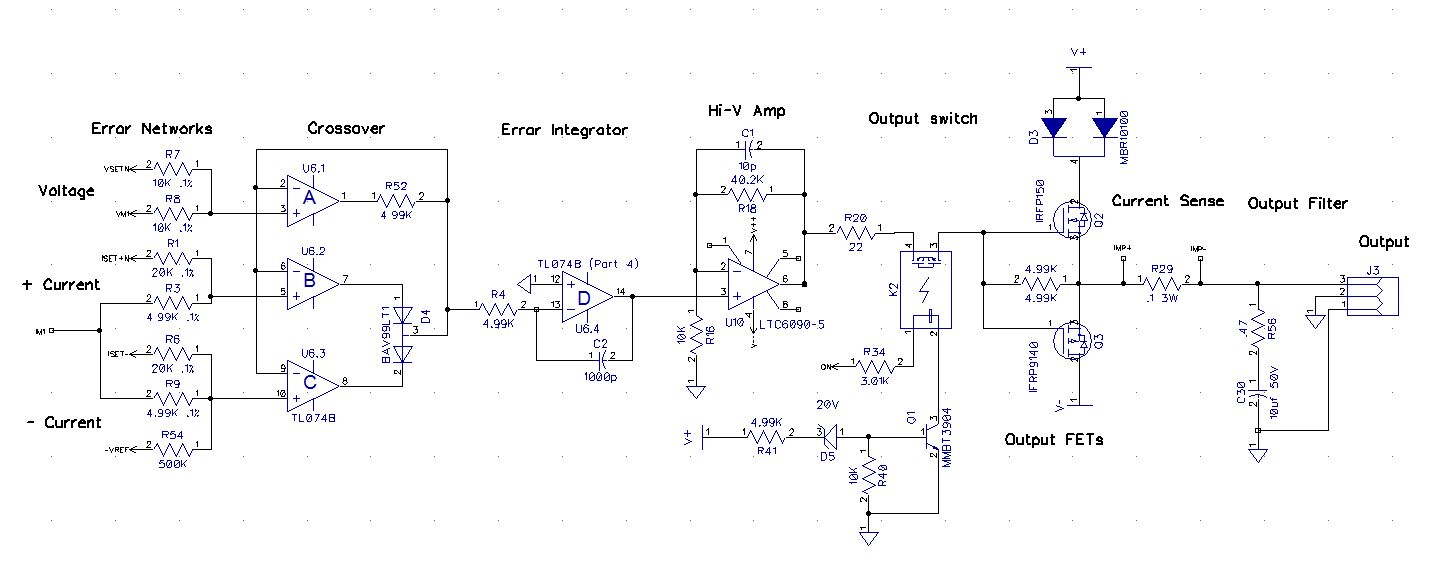

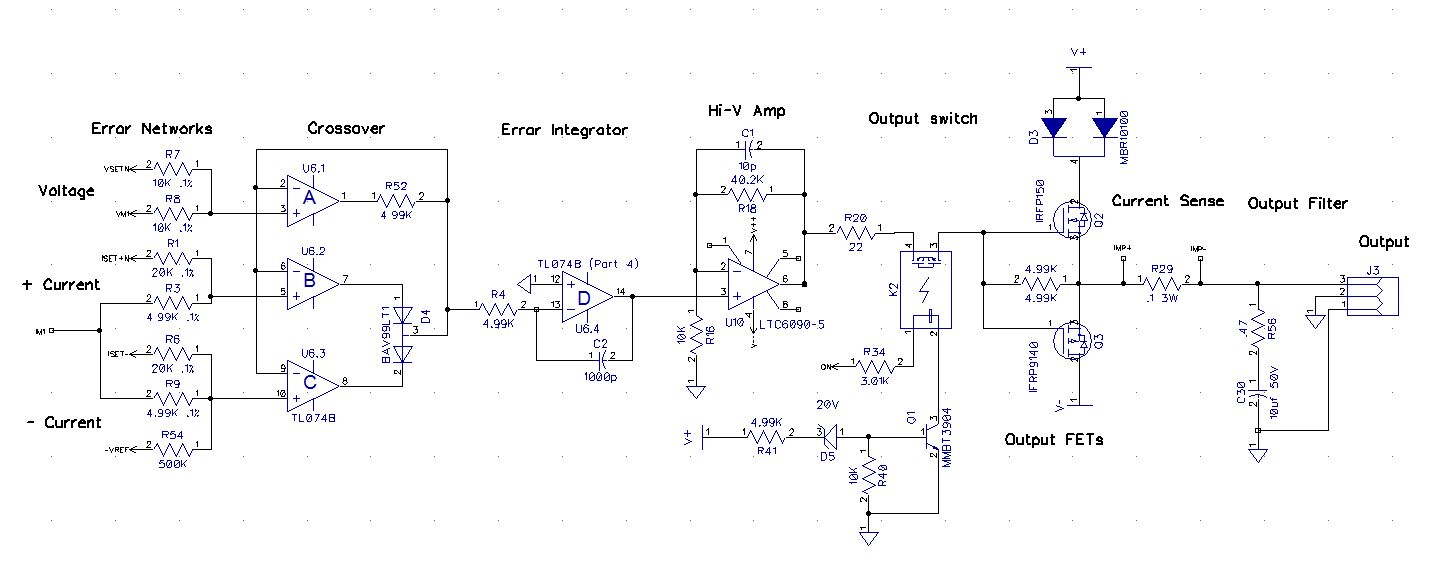

Simplified Control and output circuit for single

quadrant (+24V) version: The shut-off integrator

control circuit is not shown here.

My initial spec of +/- 24V output range can be met with a +/- 25V

power supply. These can be met with low-cost 24V switchers

adjusted to 25VDC. This allows 0.5V drop for the current shunt and

0.5V for the FET, wiring, and fuse. Figure 0.25V at 5A for the

FET, or 50 milliohms.

This type of output stage is quite simple. Both FET's gate pins

are tied together, and both source pins are connected. A single

resistor from both Gates to both Sources will turn off both FETs.

Apply a positive voltage and the + NFET turns on. Apply a negative

voltage and the - turns on. Another advantage is to use a simple

passive switch between the voltage amplifier stage and the FET

gates to turn OFF the output stage.

This type of output works well when one FET is on and when the

load changes quantity. But in the case when the load current

changes polarity, the output stage takes a few hundred uS for the

drive voltage to change the few volts from turning on one FET to

turning on the other. In an audio amplifier, this load current

polarity change occurs on every cycle of AC, and would cause

horrid crossover distortion. In the case of a Voltage / current

source, it occurs rarely and the circuit recovers quickly.

Crossover Design:

Single integrator

Crossover design refers

to the current and voltage control circuitry. It is called a

crossover because it must cleanly switch from voltage to current

control and vice versa. There are a lot of ways to implement this.

Most basic power supplies use two integrators, one for voltage and

one for current. Then diode logic is used to control the pass

element with current control taking priority over voltage control.

The disadvantage of this type of control is that when the loop is

regulating in one mode, the other integrator goes to its maximum

output. Then when the load or setting is changed and the other

integrator takes control, the output voltage or current can

overshoot while waiting for the other integrator to slew to the

correct value. Overshoot is generally bad in a power supply. This

problem only gets worse with a 2 or four quadrant device. A third

integrator is required for the load side (quadrant 2) or -current

control.

The approach I took uses a single integrator with active diode

logic to select the error voltage from either the voltage,

+current, and - current sources. There are three error amplifiers

each consisting of a basic op-amp plus a diode. These slew quite

fast to control the single integrator and so overshoot is

minimized.

Power-Off Circuit

If you analyze the

circuit of a typical power supply, you will see that things get

complicated if you apply an external power supply (battery) and

then turn off the supply. I have toasted a couple of power

supplies doing this, and since I want this PS-Load to be able to

test batteries and other sources, I designed it from the start to

be able to handle this condition gracefully.

To turn off the supply, the output stage must be somehow disabled.

with a simple load, simply setting the output to 0.0V may be

adequate. But when the load is another voltage source, the output

current must be reduced to zero. The complimentary FET

output stage does this nicely, with the single gate resistor

nicely turning off both FETs. But it is necessary to somehow

isolate the gates from the driving amplifier. I chose a

Photomos(TM) FET switch for this function. These $1 devices have

the advantage of requiring no power supply pins, and so to turn

them off, simply do not drive the LED input. So when the power

supply is off, the FET is guaranteed to be off. Perfect. A relay

would also provide this function. The Photomos devices are smaller

and never wear out. The typically switch in about 1mS and handle

milliamps up to amps, and will switch 100 or more volts.

But when the Photomos is turned off, what about the integrator?

The control loop is now broken, so the integrator will slew to one

extreme or the other. Then when you turn the switch back on, the

output voltage will have a huge glitch. You could reset the

integrator to 0V, but if the load is a 12V battery, the turn-on

current transient will be huge until the loop recovers. Not good.

One solution, used by HP in their excellent HP6632A supplies, is

when the output is OFF, to control the integrator to output the

same voltage that the output pin is. For example, if the output is

a 12V battery, the output of the integrator and driver op-amp is

controlled at 12V. Then when the Photomos is turned back on, the

FETs have no gate voltage and are initially off. This elegant

solution works very well both in simulation and in reality.

The Turn-On/Off circuit

has a few requirements. When PS-Load is OFF, I want the OFF

current to be as low as possible, preferably just a few uA. I like

the nice simple approach of using complimentary FETS as output

stages, with a simple resistor to bias them OFF. This requires

some isolation from the voltage amp when in the OFF state. I use a

Photomos solid-state relay. If you haven't used these, they are

pretty cool for low and medium current switching. They are

optically isolated and consist of an LED plus MOSFET switches.

They have on-resistances in the 50 down to 0.1 ohm range, can

output AC or DC switch voltages up to 100's of volts, and provide

thousands of volts of isolation from the LED to the switch. They

are available from a handful of manufacturers and with safety

ratings for AC line applications. They are like a relay but use

less voltage and current to drive: 1.2V at a few milliamps. They

are more reliable than relays with no moving parts or contacts to

wear out. They are small in a 4 pin SO or DIP package, and cheap,

about $1. Like a relay they do not turn on or off instantly, but

take about 1 millisecond, similar to a reed relay. Larger armature

relays take 10s of milliseconds. So one of these is used to

connect / disconnect the voltage amp to the FET gates.

When the circuit turns ON, the output voltage should slew cleanly

from its idle voltage to the voltage setting. For example, imagine

a 12V battery connected to the output. When the output is OFF, I

want minimum load on the battery. When the supply goes ON, I want

minimum transient current to occur. When OFF, the output FET gates

are held at the output voltage by the bias resistor. But when ON,

the gate voltage is switched to the high voltage amp output

voltage. If that voltage was for example 12V, this would turn ON

the P-Fet hard for a few milliseconds until the current and

voltage loops could take over. Turning a FET on hard between

Ground and a 12V battery can toast it due to the extremely high

instantaneous current. Hopefully the output fuse would blow before

the FET, but nuisance fuse blowing is also bad.

The fix for this problem is to hold the high voltage buffer amp

output near the supply output voltage when the supply is OFF. Then

when the Photomos is turned ON, the gates and sources of both FETs

are at the same voltage, and the FETs are initially OFF. A

separate voltage divider measures the buffer amp voltage and

compares it to the Output voltage. This error signal. Vbuf - Vout

controls the integrator when the supply is OFF, holding the buffer

at the output voltage. A CMOS switch, DG419, switches the

integrator input between normal operation and this difference

signal. A logic signal called ON from the I2C bus, controls this

CMOS switch and also turns on the Photomos.

I finally got a nice digital scope and can now measure power

supply transient behavior. When I hit the ON button, with PS-Load

set to 5.0V, I saw a nasty +15V transient for about 300uS.

Definitely bad power supply behavior. When the ON signal goes ON,

two things occur. The integrator is switched from the voltage amp

to the to the error amps, and the output stage is connected to the

voltage amp. But the DG419 switch for the integrator switches in a

few nS, while the Photomos switch takes about 500uS to turn on. So

the integrator starts slewing right away, but the loop is broken

for 500uS. The fix is to make the integrator control input (DG419)

as slow as the Photomos. So I added a 500uS RC delay to the DG419

control signal.

Speaking of Simulation

I generated an LTSpice

simulation for this design. Do not underestimate the complexity of

a lab power supply. They must remain stable over a wide range of

resistive and capacitive loads, and must switch from constant

voltage to constant current cleanly and without overshoot.

Designing and testing circuits for all of these conditions is

work. It is much easier to test them with a simulator and observe

the step response. Then when the simulation performs well, build

and test a real circuit.

Current Sense: Many

possible configurations

High side or low side

current sense? High side means that the current sense resistor is

in series with the + output of the supply. Low side means it is in

series with the ground. High side is required if you have multiple

supplies operating from the same raw supply. Low side is simpler

since the sense amp doesn't need to deal with common mode voltage

changes.

With the hundreds of current sense ICs on the market, this should

be easy, no? No. All current sense chips require a minimum voltage

of a few volts to operate. With a lab supply where the output

voltage can be 0V, they won't work without tricks. And forget

about measuring current when the voltage is negative. So they

don't work for either high side or low side applications.

With a high side current sense amp, common mode is an issue. Take

a typical application:a 0 to 25V power supply with a .1 ohm 5A

current sense. 5A is 0.5V across the sense R, and if you want

about 1mA accuracy, that is 100uV across the R. If the voltage can

be 0 to 25V, and you don't want the current reading to change more

than 1mA, that is 25V / 100uV = 250,000 :1 or 108 dB Common mode

rejection ratio (CMRR). Yikes! Some instrumentation amplifiers can

do this, but the problem is that the amplifiers require high

voltage power supplies. If you use a resistive differential amp,

the resistor matching is from hell. You can trim the CMRR with a

trimpot, but 250:000:1 is tough. Normal 1% resistors are spec'ed

at 100ppm drift per degree Celsius. 1/250,000 is 4ppm total drift

over the full temperature range.

I used a compromise: 25ppm 0.1% resistors (available for about

$.20) and a nice 20 turn trimpot. The circuit works quite well but

is not designed to hold that CMRR across a wide temperature range.

I2C

In the inevitable

discussion between I2C and SPI, there are many trade offs. I

generally choose I2C where speed can be slow, and isolation, and

multiple addresses (devices) are required. So for a fast

ADC, use SPI, but for this relatively slow Sigma-Delta

ADC, I2C is fine. I need DACs, a multi-input ADC, general

purpose IO (GPIO) and an EEPROM to store setting and calibration

data. In addition, I might use 3 or 4 identical PS-Load boards

in a system with a single processor controlling it all. So one

parameter I looked for in selecting the I2C peripherals was the

ability to easily select 4 I2C addresses per each device.

Isolation

A system power supply needs to

be isolated from the computer system that is controlling it.

Imagine a USB interface to a non-isolated power supply, and the

operator accidentally shorts the 24V 3A output to ground. That

will cause 3A to flow through the AC ground pin, or worse, the ground pin of the USB cable to the PC. Not good.

For this and other reasons, isolation is needed.

I2C isolation is a bit tricky since at least the Data wire needs

to be bi-directional. For multiple masters (rare) the clock would

also be bidirectional. Fortunately there are I2C specific

isolators that address this trickiness. I use the ISO1541 from TI

in a SO8 package for about $4.

Power Supplies

The system can use any raw

power supply including low-cost switchers, and conventional

transformer / diode / caps. To generate 24V, I use a

low-cost 24V switcher set to +25.5V so the supply can output 24V

at full current, including wiring, shunt resistor and FET losses.

In addition to the raw supply, the FETs need "boost" supplies. I

discussed these earlier.

In addition to these, the analog circuits need +/- 12V for the

analog stuff, +5V for the I2C stuff, and an isolated +5V for

the control processor.

For +/- 12V, I use a low-cost DC-DC from CUI. The 5V is a fairly

low current (a few milliamps) so I use a 5V linear regulator from

the +12V. For the isolated 5V to drive the processor, I use a

small, isolated DC-DC. Note that any isolated 5V supply can

be used. In fact if multiple channels are used, only one isolated

5V is required. and so channels 2 though 4 should not have the 5V

DC-DC installed.

ADC

After using the

Microchip16/18 bit 4 channel Sigma-Delta ADCs (MCP34xx) on

previous projects, I chose it for the ADC on this project. 16 bits

at 7.5 samples per second, but the cool feature is the ability to

measure +/- 256mV with a single +5V supply. Bipolar current and

voltage measurements need bipolar measurements. The part only uses

an internal reference, and doesn't bring it out as a pin, but it's

15ppm/C drift is quite good. I only use 2 of the 4 channels in

this design, but the 2 channel parts don't have I2C addresses, so

I use the 4 channel part here.

DACs

DAC INL (Integral

Non-linearaity) is a critical spec for a programmable voltage

source. It directly affects the accuracy of voltage and current

settings. It is important to get an accurate value when you

request it. Offset and gain errors can be calibrated out, but to

get accurate values at all settings, low INL is needed. Many

system power supplies use expensive14 or 16 bit DACs for this

purpose. I need 2 or 3 channels, one for Voltage, one for Positive

current, and one for negative current. I need 12 or more bits with

good INL, and low cost. Unfortunately most low-cost 12 bit bit

DACs have high INL, like 4-12 LSBs. 12 or more LSBs of INL is

equivalent to an 8 or 9 bit DAC. I found the Maxim MAX5815 quad 12

bit DAC that has +/-1LSB of INL Max. and is about $5. Yes, it has

address select pins. And they throw in a sweet 10ppm/C

reference. I use it for the other circuits that need a stable

voltage.

Another way to get better INL is to use the more accurate and

higher resolution ADC as feedback, and adjust the DAC setting.

With this approach, the initial setting will have the full DAC INL

error, but then the ADC corrects it. This causes a somewhat

strange settling response as the firmware control loop hunts for

the best DAC setting. I'm not sure this is an acceptable behavior.

Calibration

There is an I2C EEPROM

per channel that will ultimately contain the calibration factors

for that channel. But implementing proper cal firmware and EEPROM

storage is a lot of work, which I have not done yet. For now, I

simply hard-code the cal factors in the Arduino firmware. Since I

currently only have 2 boards built, this is a reasonable approach.

For each board, there is a table like this:

#ifdef BOARD1

Set[DVS].range_max = 25.0;

Set[DVS].set_max = 25.0;

Set[DVS].range_min = 0.0;

Set[DIP].range_max = 5.0;

Set[DIP].set_max = 3.0;

Set[DIP].range_min = 0.0;

Set[DIN].range_max = 5.0;

Set[DIN].set_max = 5.0;

Set[DIN].range_min = 0.0;

// Offset and Gain for all ADCs and DACs

Set[DVS].gain_cal = 0.939145;

Set[DVS].offs_cal = -0.022;

Set[DIP].gain_cal = 0.99475;

Set[DIP].offs_cal = -0.022;

Set[DIN].gain_cal = 1.00000;

Set[DIN].offs_cal = 0.0000;

Measure[VM].offs_cal = 0.004;

Measure[VM].gain_cal = 0.99534;

Measure[IM].offs_cal = -0.011;

Measure[IM].gain_cal = 0.99161;

Measure[VM].range_max = 13.00;

// 2Q: /13 only

Measure[IM].range_max = 20.0;

// .1 ohm = 10V/A

Set[DIP].value = 3.000;

// Set initial current values

Set[DIN].value = 3.000;

#endif

To begin calibration, I set the offsets to 0.00 and the gains to

1.00. I start by calibrating the16 bit Voltage ADC: apply 0.0V to

the output (a short or low value resistor, power supply OFF) and

see what the voltage display reads. Lets say it reads +0.015V. So

the voltage measure offset, Measure[VM].offs_cal is -0.015V.

Then set the output to about +20V and compare the measured

(display) and expected (DMM) values. Divide them, and that is what

you wold need to scale the measured by to obtain the expected.

Set Measure[VM].gain_cal to that number. Do the same for the

current readings.

Once the measure circuit is working, you can use it to measure and

calibrate the voltage DAC and two current DACs. I generally enter

the offset number and recompile before calibrating the gain. More

compiling, less thinking. The first time you do this will will

take a bit of time, but once you get the hang or it, maybe 20

minutes to calibrate everything. Notice that I got lazy and did

not cal the negative DAC [DIN] yet.

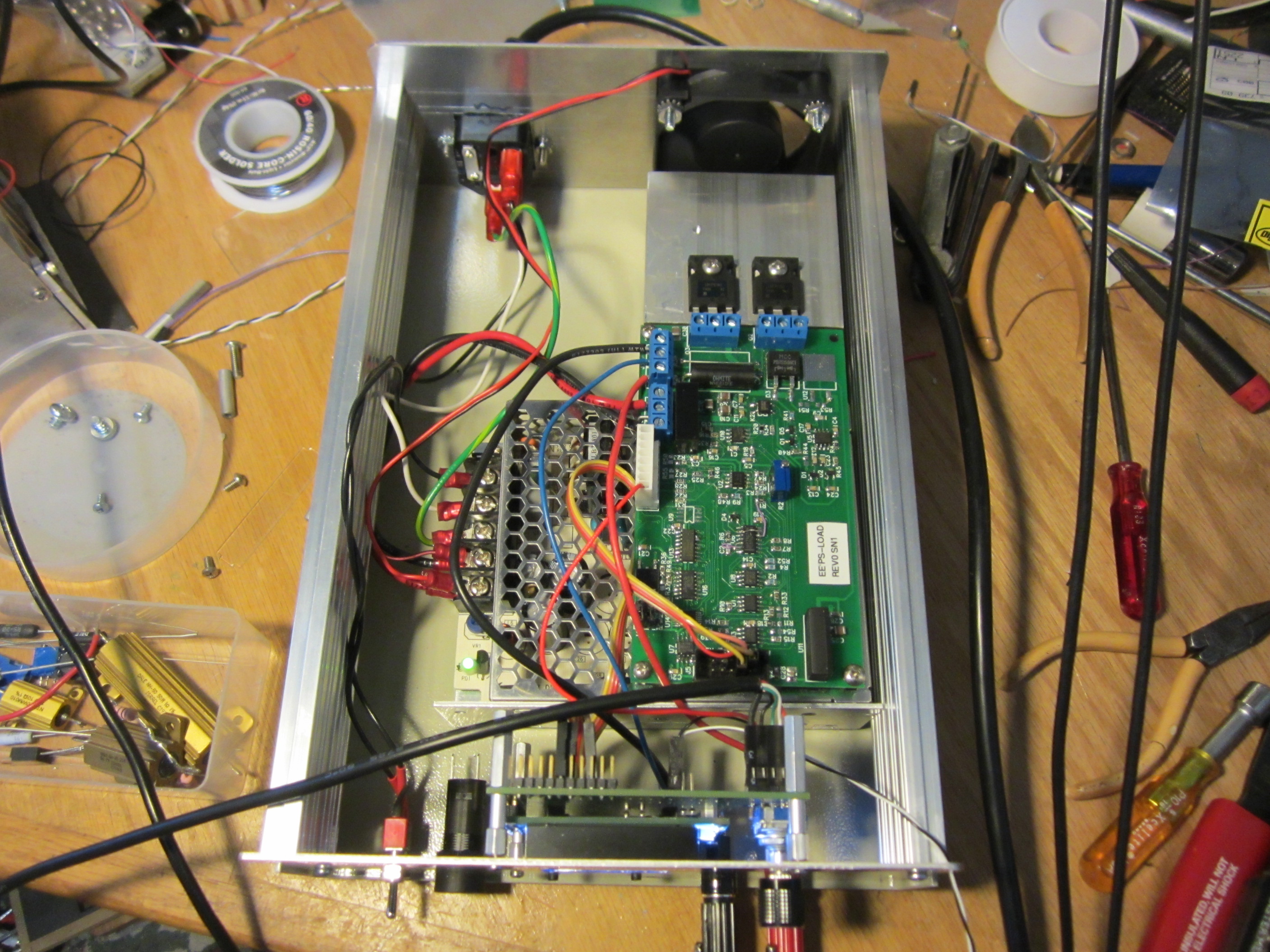

Enclosure

My goal is to minimize

the case size. I would like to fit a single channel into a

small 2U (3.5") high by 1/4 rack (4.25") wide case. Length should

be 10-12". I came across a large batch of free Hammond 1402F

enclosures. These are 7x10x3", and fairly attractive. Here is a

single channel system in a Hammond case. Note the switching supply

beneath the PS-Load board. For an AC inlet I use a fused version,

although switching supplies already have AC fuses. If the design

uses a transformer, then a fuse is required. Also since I run AC

to the front panel, an AC fuse is a good idea.

For a heat sink, I used a 2.6 x 1.5 x 2.4" one cut from a larger

heat sink I found on Ebay. It is a bit too small to dissipate

50-75W, so I currently run at a bit lower power. The 24V fan blows

air out of the enclosure, which I think is not quite as efficient

as blowing cold air directly onto the heat sink. I still have some

work to do here. Ideally I would find a larger heat sink. Note

that for two or three channels, a single wider heat sink could be

used and multiple boards could be mounted side-by-side. Currently

the height of the heat sink and the switcher are about the same,

so I just mount a couple of short spacers on the switcher to hold

the front two mounting holes of the board. It's a bit of a hack,

but it works. It requires removing the cover of the switcher to

mount the spacers, nuts, and washers. You could also just use long

spacers for the board. The switcher fits between the board

mounting holes.

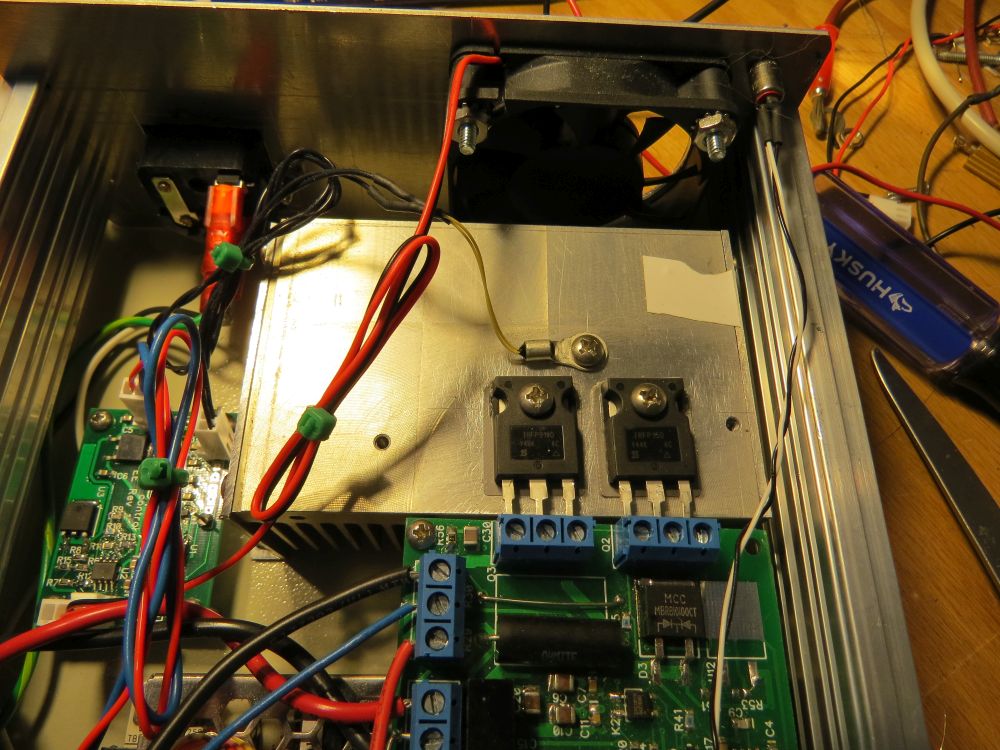

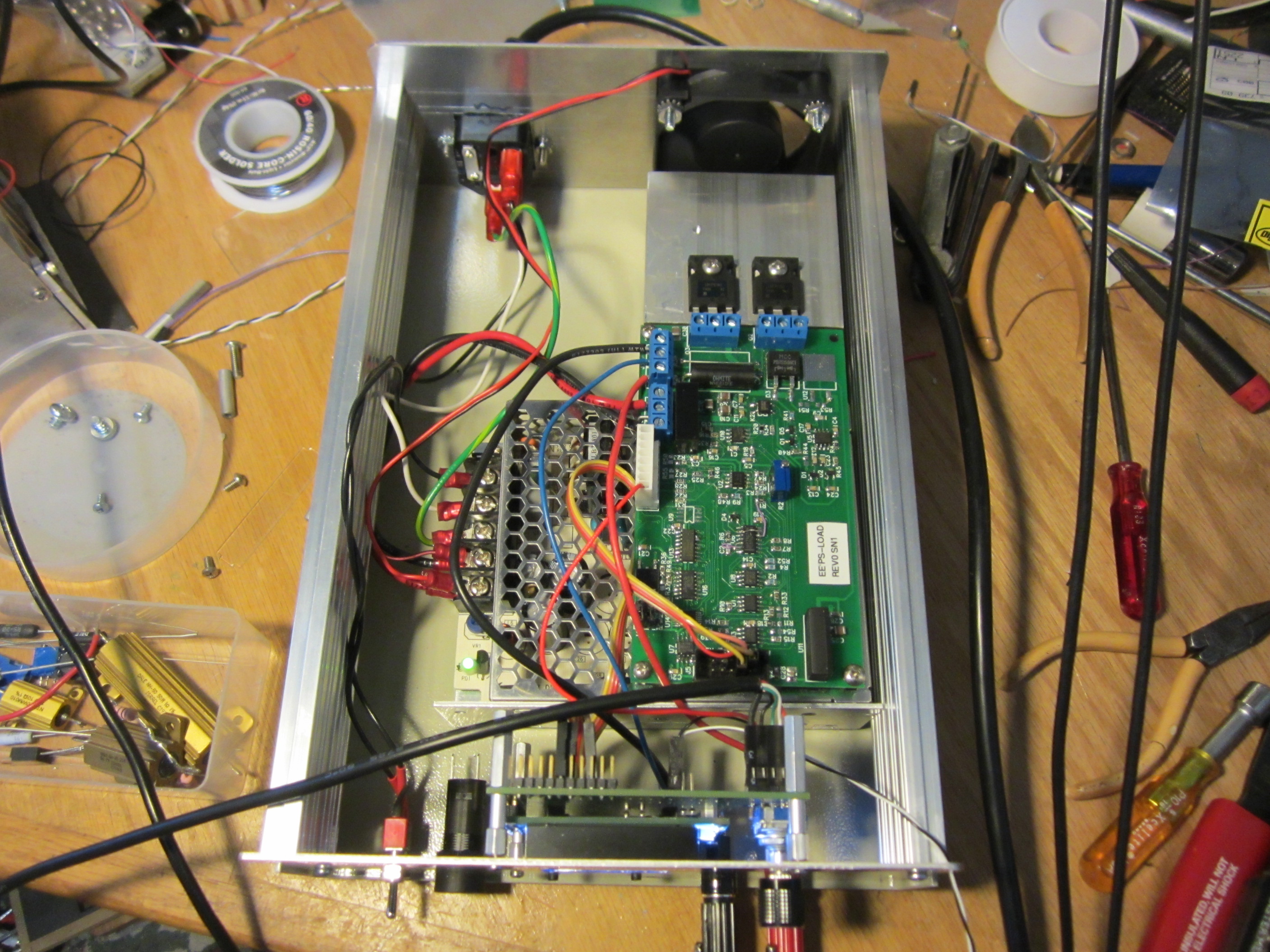

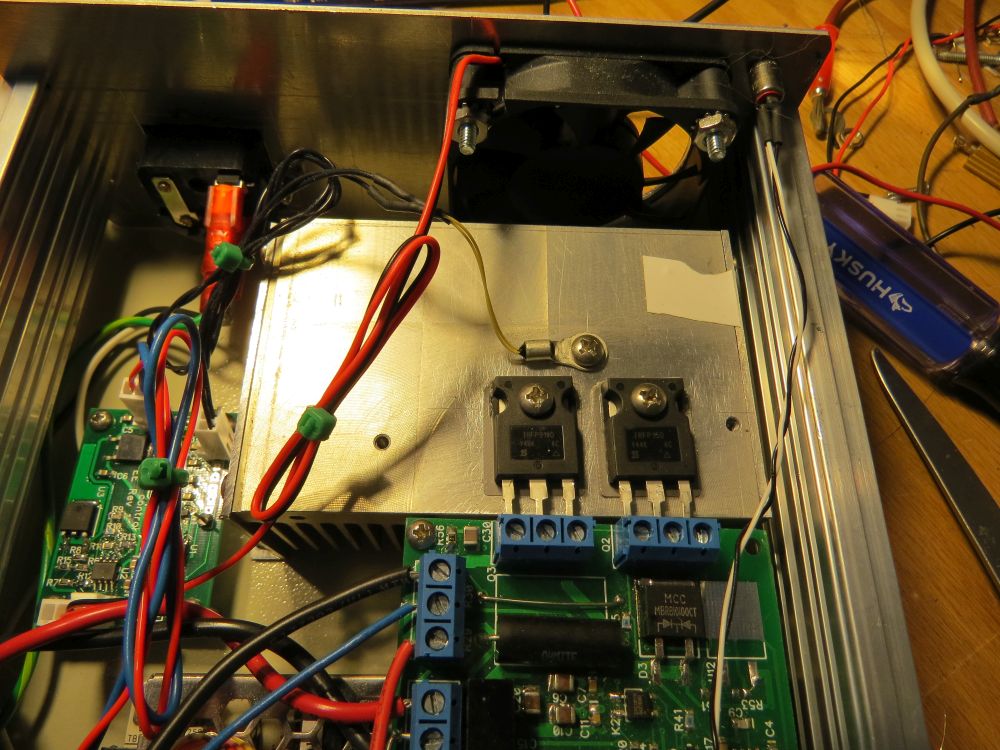

Internal view with the original heat sink and no fan board

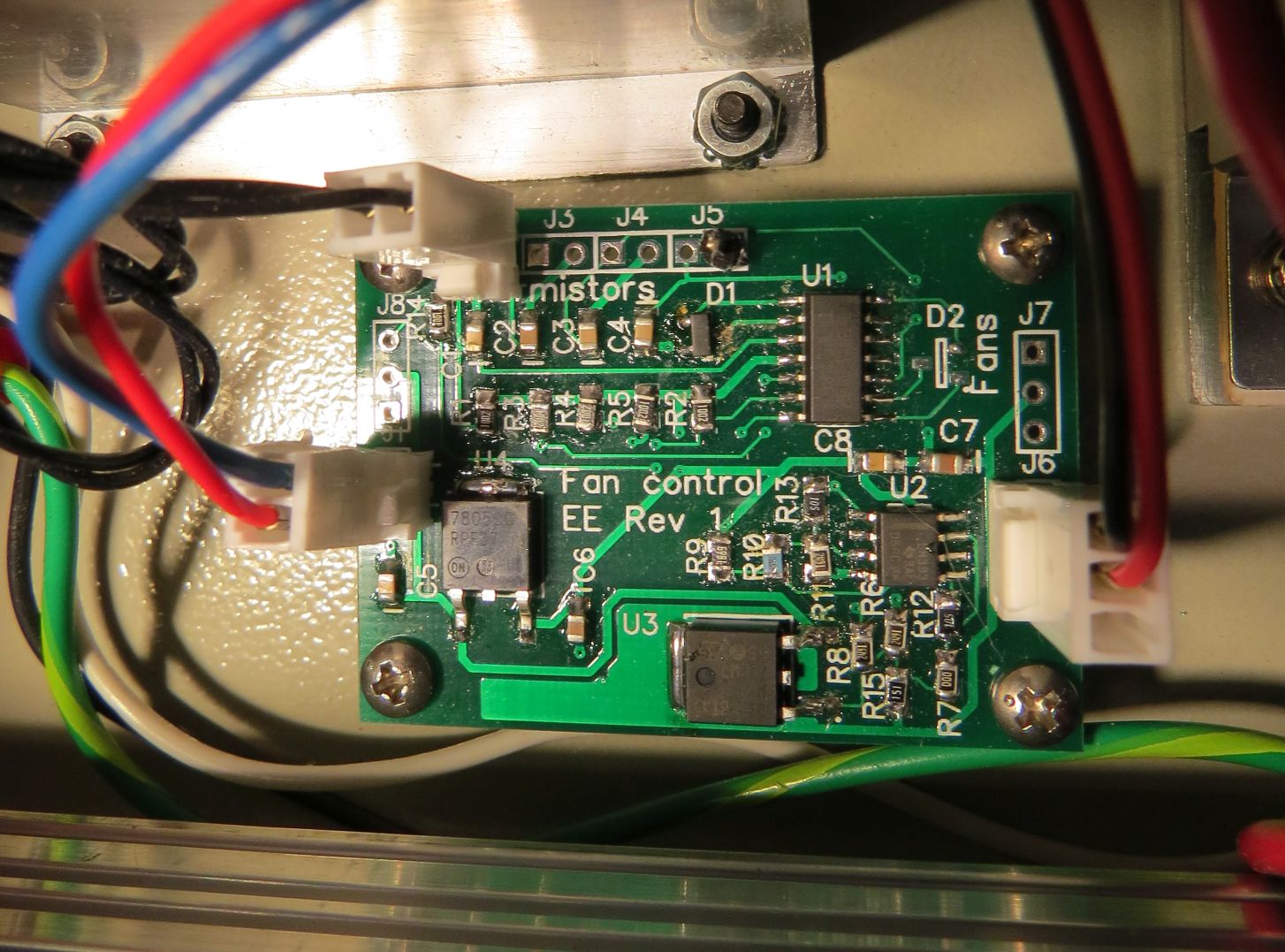

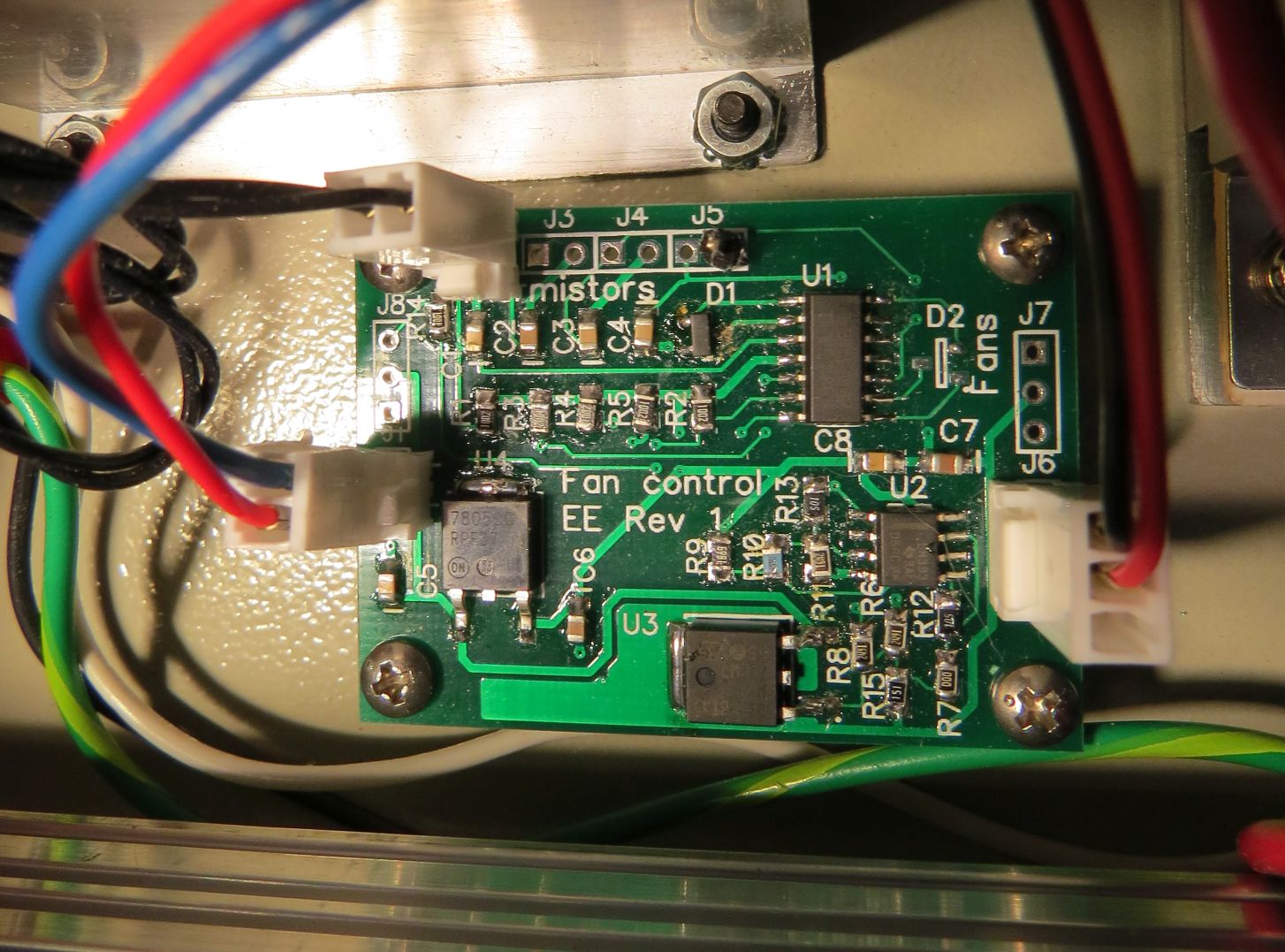

New heat sink with thermistor and fan board installed.

The original heat sink was a bit small and did not cool

efficiently. Too much of the cooling air diverted around the heat

sink. Also it had no mounting features. I purchased another large

heat sink extrusion on Ebay, cut it to size on my trusty table

saw, and mounted it to two small angle brackets. It is raised

about .25" off the chassis bottom to allow air to flow efficiently

past it. This new one works well. Ideally there would be fins

above the heat sink as well as below it. Here is an off-the shelf

Wakefield 395-1AB that is about the right size, should work

nicely and costs about $22.

Front panel controls, Encoder, push buttons and LCD. No Green

binding post yet.

Fan Control

A thermally controlled

fan is generally good. When the supply is not outputting much

power so the heat sink is cool, the fan can be OFF. When it is

operating at max power, the fan is ON full. In the middle it wold

be nice to have th4e fan ON but quiet since no-one wants to hear a

fan that is on unnecessarily or is constantly varying in speed,

the sound is annoying and distracting. So the speed should

change only when it needs to. It's a trade-off between optimal

cooling and noise. My design is for 3 fan speeds: Off, full on,

and medium. This should do the job and minimize fan speed changes.

Most DC fans are 12V, but I have lots of 25V power and little 12V,

so use a 24V fan. But the fan controller should also accept 12V

power and drive a 12V fan. I might want to have multiple heat

sinks or a large one with multiple temp sensors. I might want to

have 2 fans. Since the 24V is electrically isolated from the CPU

or I2C control, any feedback or controls from the CPU to the fan

would need to be isolated. Fan power isolated from GND and other

supplies

- Temp detect on

multiple heat sinks 1 through 4? 2?

- Lug style

thermistors: one screw mounting, good thermal contact, no

isolation hardware required.

- Control the fan as a

function of the maximum of multiple thermistors. So maximum

logic is needed

- Alarm? 3rd

comparator, LED or audible, notify processor when a max

temperature is exceeded.

- Three settings

minimum:

- Off

< 40C, fan V < 2V

- Medium,

40-60C, fan voltage ~12V

- High:

> 60C, Fan 23V

- Hysteresis to keep

speed from varying.

I considered a few

approaches, mostly by having the Arduino control the fan. Finally

I decided that boards are cheap and I just needed a variable fan.

So I built an analog circuit that can accept 1 through 4

thermistors, drive multiple fans, and has 2 setpoints for 3 fan

speeds. Here is the schematic

and PCB. By the way, this is my first PC board order from

PCBWay.com. $10 for 5 boards, $8 shipping, 3 weeks delivery.

The maximum temperature circuit is actually a minimum voltage

circuit since high temperature on an NTC thermistor causes low

voltage. It uses a quad op-amp and 4 schottky diodes to output the

minimum of 4 thermistor voltages, representing the hottest of the

4 thermistors. I looked up the two temperature setpoints, 40C and

55C. The desired fan voltages are 0V, 12V and 23V. 12V is pretty

quiet, 23V is the maximum that the LM317 regulator can output with

a 25V input. These temperature setpoints correspond to voltages

when used with a 5V supply and a 10K bias resistor, or 1.50V and

1.25V. Then I built a simple 3 resistor chain to provide these 3

voltages. The temperature and the setpoints are compared via two

LM393 comparators, which drive resistors that set the LM317 output

voltage. Whew!

The BOM cost of the board with a single thermistor and one fan

output is about $2 plus $1 for the board. For thermistors, I use

Lug mounted. These are a bead type thermistor mounted in a copper

lug that can be mounted to a surface with a single screw. They are

about $1.

Schematic

The schematic was designed in

DipTrace. After considering the usual low-cost CAE options, I

decided on DipTrace. Unlike most CAE tools, I like it. For

years I used ExpressPCB. They were the quickest and lowest cost

way to get prototypes. But their file format is proprietary, and

many offshore vendors now produce boards much cheaper than

ExpressPCB, and require Gerber file formats. It was time to update

my skills to a real PC design tool.

I attended a Synthesizer conference at Olin College in Needham,

MA. I spoke with an EE professor there and asked him about

building prototypes for students. He said that he regularly

assigned a schematic and PCB project to students to do over a

weekend. Students who had never drawn a CAE schematic or laid out

a PC board could download and learn DipTrace quickly. When I tried

it, I was pleasantly surprised and have been using it for the past

8 months.

files/ps-load1.pdf

Costs

The BOM has costs

included. The parts on the PS-Load board are about $50, Qty 100,

pretty reasonable. In addition, A 75W 24V, 3A switching power

supply is $27. The heat sink cost is about $5-10. I buy surplus

heat sinks on Ebay and cut them to size. Then a case, 24V fan, AC

inlet, AC switch, and banana jacks.

For the front panel board, a PCB, LCD, Atmel processor, crystal,

USB connector, a couple of buttons and an encoder. I estimate $20

cost.

Front Panel

Board

I used the front panel

board of my Arduino Panel Meter for the processor and controls. In

addition to an Arduino Leonardo compatible (ATMega32U4) processor,

it has an 8x2 LCD, an encoder knob and positions for push button

switches. The panel Meter has isolated data acquisition circuitry

which I bypassed, and brought out its I2C circuitry. It was a good

match for this application. While the small 8x2 LCD is OK for a

single channel unit, it is a bit too small for a multi-channel

system, and the digits are fairly small. My plan it to lay out a

16x2 version that can use either a small or large digit LCD.

Firmware

I wanted to use all

Arduino code for this project to make it as accessible as

possible. I like that Arduino can do basic math in floating point

and still fit nicely in a 32KB memory. The code uses the wire

library for I2C, and the LCD library. One problem with Arduino

libraries is that they tend to use polled methods as opposed to

interrupts. I like to read front panel controls including encoders

in a 1mS or so timed interrupt routine. Fortunately the Arduino

also uses a 1mS timed interrupt using Timer0. I found a trick of

adding a second output compare to Timer0, which creates a second

interrupt. You can adjust the compare value so the second

interrupt occurs roughly halfway between the Arduino interrupts,

thus avoiding conflict. Then you can add your own code to this new

interrupt. I used this technique to create an interrupt where I

poll and debounce the keys, and to poll the encoder. Keep in mind

that this interrupt isn't exactly 1mS, but is 16Mhz / 64 /

256 = 976.5625 Hz. Arduino timer routines compensate for this

error.

Switching Power Supply

Common-Mode Noise Issue

Here is a more thorough

discussion of AC-DC and DC-DC common-mode

noise.

With any power supply, either lab or otherwise, common-mode noise

is an issue. When you float a power supply, there is always some

AC current flow from the power supply ground to the chassis (AC)

ground. With a linear supply, this is usually a small amount of

60Hz current due to the inter-winding capacitance between the

primary and secondary windings of the power transformer. With a

linear supply, the frequency (60Hz and some harmonics) and the

capacitance (50-200pF) and the 240VAC input causes about I = V /

Xc = 240/(1/2*pi*60Hz * 200pF) or tens of microamps. No problem,

and the typical .01uF safety cap to ground shunts out most of this

current. In the case of a high-class power supply or a

precision instrument, the AC transformers are usually double or

even triple shielded with metal foil between the windings. This

shielding reduces the common-mode noise current significantly.

However with a switcher and its high frequency transformer, the

frequency is not 60Hz, but the harmonics of the the fast rise-time

switching waveforms: rise times of 300V pulses can be about 100ns

causing pulses with harmonics of 10MHz or more. The transformer

windings are usually smaller, so the inter-winding capacitance is

a bit less. Just to meet radiated and conducted EMI, the

transformers are often shielded. You will sometimes see copper

foil on switching transformers.

Still, I see some pretty ugly looking common-mode switching noise

on many switchers. Manufacturers do not specify common-mode

noise, so how do you deal with it? How do you quantify it? Search

for this problem on line and you will find little specific data or

techniques. In fact, to meet EMI, Switchers are often tested with

a short and heavy wire from their DC common to the chassis ground.

This effectively shunts any common mode noise to ground. But if

your application requires a floating supply, you are on your own

dealing with this issue. Measuring the open-circuit voltage is

interesting. You will typically see a few volts of high frequency

crud. Why not 100V, since the switcher is switching hundreds of

volts? The answer is that switchers do have a capacitor from AC to

DC ground, typically between .01 -.05uF. This is a safety rated

cap in case the ground of the system is accidentally opened up.

This common mode voltage or current can shows up as noise on audio

or other critical analog circuits. It basically causes an

unavoidable AC ground loop at high frequencies. If you need a

switching supply to float, beware.

To measure the common-mode noise of a power supply, I use a simple

current measurement. A 10 ohm resistor has bandwidth out to the

GHz range. Wire a 10 ohm 1/4W resistor between the chassis ground

pin and the DC common, usually V-. Measure the voltage across this

resistor with a 20MHz or 100MHz scope, and you have a good

indication of the high frequency common-mode currents flowing

through the supply. I did this on several switchers and as

expected, most had about 1V p-p of crud across 10 ohms or 100mA of

switching currents. But to my surprise, I found some

switchers are quiet, measuring less than 20mV across 10 ohms or

just 2mA! What do they know that the other guys don't?

To investigate this, I first measured the capacitance from GND to

V-. All supplies measured about .02uF, meaning that the

manufacturer typically uses a .022uf capacitor there. So I opened

up the bad and two good ones to see what the difference was. The

bad ones use a safety-rated, thru-hole, ceramic disc cap from V-

to GND. Seems reasonable. But the good ones use an array of 3x2

surface mount capacitors and much shorter and thicker PC

traces. And they mount the capacitors directly between the

V- and GND pins of the supply. This approach minimizes the circuit

inductance and therefore the high frequency noise. Nice.

Who is good and who is bad? All the CUI (V-Infinity) supplies I

measured (n=3) were bad. All of the TDK-Lambda supplies (n=2) were

good. I will be using TDK-Lambda switchers from now on when I am

concerned about noise.

2023 Update: PS-Load

MkII

I have been thinking of

an upgrade to PS-Load for a while. DIY-SMU does a good job at high

and low voltages up to +/- 150V, and at currents from nA to 100mA.

But higher currents are sometimes needed. The 2 line LCD is dated

and the enclosure is not ideal. There is no SCPI interface.

DIY-SMU needs a big brother for higher currents. A higher current,

lower voltage unit is useful for:

- Power transistor and

FET testing

- Battery testing

- Solar panel testing

- A general power

supply.

Proposed updates to

PS-Load:

- Rev2 PCBs

- Proper case

- Proper front and

rear panels

- Maybe Gobilda

rails

- Lower BOM cost than

DIY-SMU, ~$200 parts cost vs. ~$450 for DIY-SMU

- 1 or 2 channel units

- GUI TFT touch

screen, or at least OLED

- Looking at 2.4"

OLED 128 x64

- New CPU: Nano

Every, Teensy, RPi Pico

- 24V at 3-5A, 48V at

2-3A

- Higher current and

voltage versions are possible

- Multiple FETs,

larger heat sink...

- Two quadrant

operation is preferred since 4 quadrant is:

- More complex and

expensive than 2 quadrant: 2 power supplies...

- Very inefficient

when used as a high-current load

- Unnecessary for

90% of uses

- When negative

Voltage is required, output polarity can be reversed.

- Low side current

sense

- Requires diff amp

for V sense

- Eases CMRR

requirements on current sense

- Fan control

integrated on CPU

- Needs 48V fan for

48V version or 48-24V supply

- Maybe just PWM a

24V fan? Hmmm....

- SCPI over USB

- Higher precision

- 14-16b DACs vs.

current 12b

- Probably requires

change from I2C to SPI

- Higher precision

ADC? MCP3564 looks good, low cost, available.

- Maybe 1 or 2 lower

current ranges

I have begun doing the

code. I only ever built 1.75 PS-Loads, one is in a case and I

occasionally use it. The other is just an open breadboard with

heat sink, and is configured as a 4 quadrant unit. I could

reconfigure it as a 2Q unit, but I think I'll modify the 2Q unit

instead.

I began with a LeoLED and the 18b Code. This code has OLED

display, Encoder, Digit select buttons, underline cursor select,

and SCPI. The SPI needs to be converted to I2C, and the display

needs to be rewritten from a character LCD to OLED.

The painful part of the code porting is setting the 3 parameters

(V, I+, I-). It entails three displays along with digit cursors.

Each numeric parameter that needs a display and set function

requires a Value, a Label, and a Units display.

- XY position on

display

- Relative XY

positions for value, label and units

- Size / fonts for the

above

- Decimal point

position

- Value

- Cursor position:

digit width and Decimal point width

All these need to be

managed. It's kind of a pain. On a character display, underline,

block and inverse video cursors are real simple. Not so much on

a graphics display. Since the 60's, data terminals, computers

and even lowly character displays manage cursors for you. The

fonts on Graphics boards, not so much, you are on your own to

manage the cursor. I think this needs a big function and data

struct to manage it all.

I finally stopped

whining and wrote some code. I modified Board #2 from 4Q

(quadrant) back to 2Q. Having a second unit is always good. I

began with a LeoLed and set it up to display the Vmersure,

Imeasure, Vset. I'm also messing with a larger 2.4" OLED.

Still 128 x 64, it has blocky pixels, but I like the larger

size, and it seems like a good deal. $15 from Amazon. I spent a

few hours debugging a bad 10 pin IDC cable! I got the cursors

working on it, it wasn't too bad with a few #defines. When I

added the final 2 numeric displays, the firmware crashed! I

removed, them and it worked fine. I think I finally hit the code

size limit for an Arduino Leo. We're gonna need a bigger

processor. Candidates are Nano Every, RPi Pico and Teensy.

Normally I'd go straight to a Teensy 3.2, but they are now

obsolete. So is the Teensy LC. THe only Teensy's are the 600MHz

Teensy 4. Seems like overkill.

I tried to get it

working with Arduino Nano Every for a while. At first I couldn't

get Nano Every working with an SPI OLED. I considered using I2C,

but I2C is slow and uses a lot more CPU cycles to update the

display. I couldn't find any Every OLED SPI examples on

line and the documentation wasn't real helpful. I couldn't find

the SCK, MISO and MOSI pins on Nano Every. Turns out Arduino

changed MOSI to COPI and MISO to CIPO! This came as a surprise

to me initially. Can't justify that old Master-Slave language,

it's got to go. I finally found an example for another SPI

device, and the SPI pins were revealed. Hooked up the LCD and

presto! Next I needed to modify my low-level interrupt code to

generate the 1mS interrupt using timer 1. This took a few hours,

and I finally found a good example

on-line. Here's my code. I used this opportunity to

modernize my interrupt code from the old SIGNAL type of ISR.

In setup()

// Set Timer 0

compare to about 1/2 of the 256 cycle to not interfere with

Arduino mS timer.

TCA0.SINGLE.CMP1 = 128;

TCA0.SINGLE.INTCTRL |= bit(5); //

bit5 CMP1 Int enable

Nano Every Interrupt

function:

ISR(TCA0_CMP1_vect) {

cli();

TCA0.SINGLE.INTFLAGS |= bit(5); // Clears

the interrupt flag. Rather confusingly,

digitalWrite(TESTPIN, 1);

getEncoder();

getKeys();

digitalWrite(TESTPIN, 0);

sei();

// Use bit(4) for CMP0, bit(5) CMP1, bit(6) CMP2

}

This new interrupt code

works well on the Nano Every.

I still haven't

decided, Nano Every, Pi Pico, or other. I'll try using a Pi Pico

next. Pi Pico is a bit frustrating. There are at least 4

incompatible programming methods in use: Micro Python, Arduino

MBED, Older Arduino, and C/C++. Finding code for the one you use

can be frustrating.

I messed with these for

a few days looking for a simple 1mS timed interrupt for Arduino

MBED, but no love. As much as I hate to do it, I may need to

read the damn register description, figure out what timers

Arduino uses and if there is spare compare, and then

figure out how to write Pi Pico registers. If you want something

right, do it yourself. Hopefully this pain is not a sign of

things to come when using Pi Pico.

What's the problem? The

problem is that the timer architecture of Pi Pico is different

than others. Instead of a short (8-16b) counter with several

output compare registers, it uses a 64 bit counter which ideally

never rolls over. So timers are implemented as 'alarms' which

you set in the future. To get a regular interrupt, every time

there is an interrupt, it require requires that you add a

constant to the compare register to get the next one. This is

similar to what the 68hc11 processor timers did in the '80s. An

other possibility is to use a separate PWM with interrupt. Hate

to waste a PWM, but in my case I don't generally use many PWMs.

But after searching and trying a few things, no love. I'm giving

up on RPi Pico for now and using Nano Every instead.

BTW I have implemented

a 1mS interrupt timer on every processor I've ever built

including MC68HC11, Many AVRs, STM32, esp32, and Teensy. All

were pretty easy. But not the bloody RPi Pico.

2024 update: I also

like Adafruit's ATSAMD21. These are ARM M0, have a bunch of

memory and I/O have decent 12b ADCs, and are $12 or $20. No

problem getitn a 1mS interrupt using the Adafruit library.

IO Expansion Tricks:

More IO pins

But, the Nano-Every CPU

is running out of I/O. It only has 30 pins, and many of the pins

are not I/Os. This app has 8 buttons, 2 inputs for the encoder,

and two outputs for the 2-color LED. Also has I2C and SPI.

Unless I resort to tricks, every I/O pin is being used. Here are

some tricks to expand I/O.

- Use an I2C or SPI

I/O expander. I read the buttons with a 1mS interrupt, and

interrupt routine should be fast. So no I2C or SPI. And these

expanders cost real money ($1-2)

- Use a 74HC594/5 to

generate more Outputs. I only use 2 GPIO outputs, so that's

not a win.

- Use an analog mux

'4051 or '4052. This is a good way to save a few I/O pins.

Using a 74HC4052 dual 4:1 mux costs 4 pins and makes 8 inputs,

so a gain of 4 pins, for only $0.30. Because they are analog

switches, no extra pull-ups are needed.

- Use some other logic

tricks. But logic tricks require logic levels, and I'm spoiled

by the Arduino built-in pull-ups. External logic would require

pull-ups per switch. If you don't mind the extra pull-ups, a

digital 8:1 (74x151/251/252) or dual 4:1 (74x153/253) can be

used.

- Multiplex the

switches. Unfortunately 8 switches require a 4x2, 2x4 or 3x3

array. And these all take 6 pins, so a savings of only 2 pins.

- Use a bipolar

Red/Green LED and drive it with one pin, using a

pull-up-pull-down resistor two 330 ohms to VCC and GND. Turn

the Output pin HI for red, LO for green, and OFF (set to

input) for LED OFF. This saves one pin and costs nothing.

- Use CharliePlexing. Only diodes are needed.

CharliePlexing switches and LEDs

I only recently (2024)learned about this. Charlieplexing is based

on the fact that most processor I/O pins can be inputs or outputs.

With LEDs, no diodes are needed. With Switches, diodes are

needed. 6 switches can be read with 3 I/Os, and 12 switches

can be read with just 4 I/Os. 5 I/Os can read 20 switches.

To avoid 'shadowing' where multiple switch presses can cause an

error, one diode per switch is needed.

Here is a good article about Charlieplexing. http://www.pcbheaven.com/wikipages/Charlieplexing/

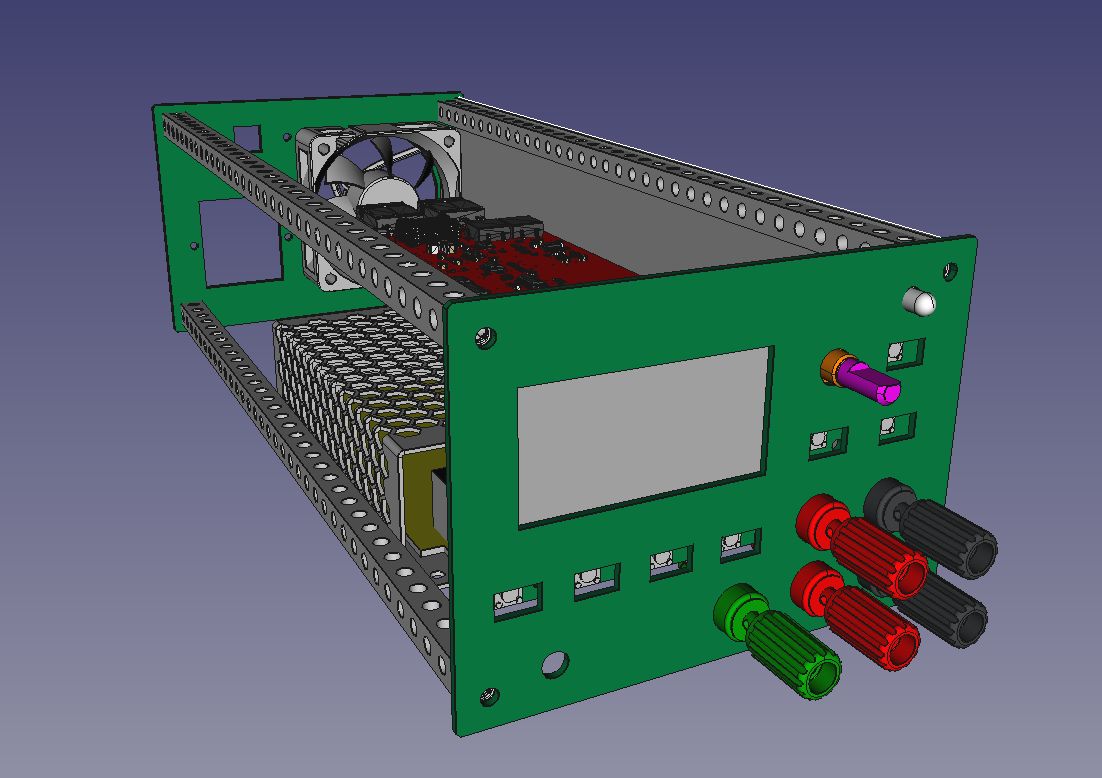

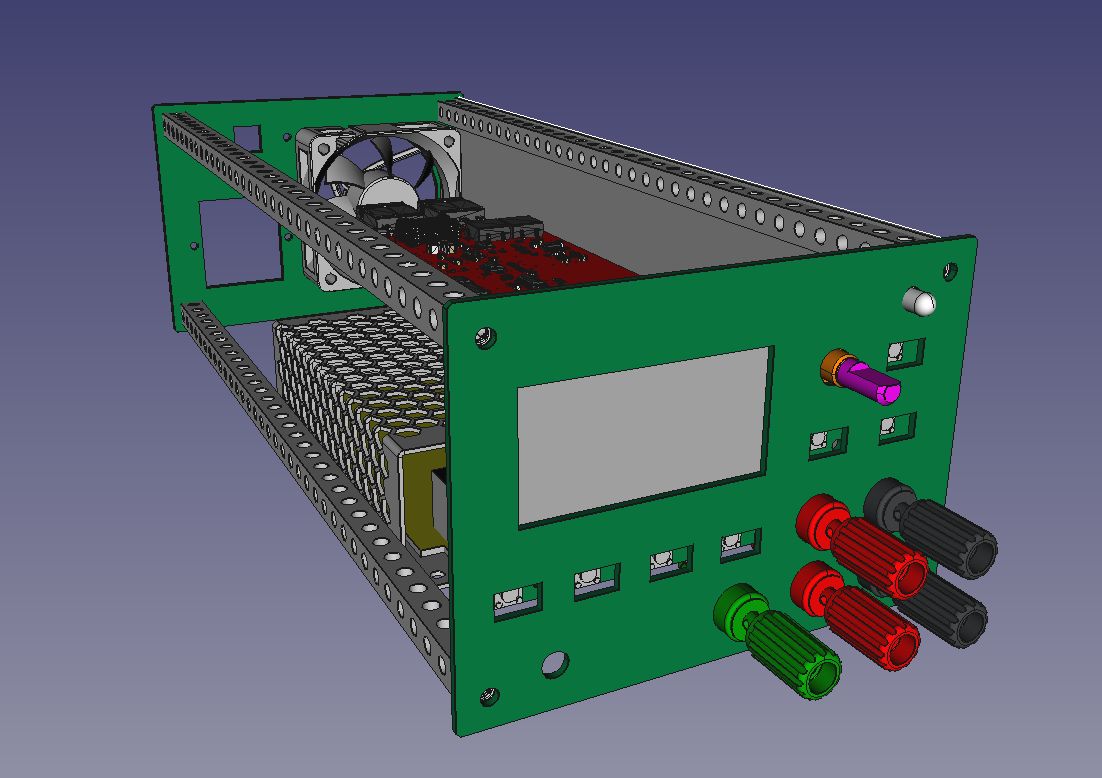

Enclosure

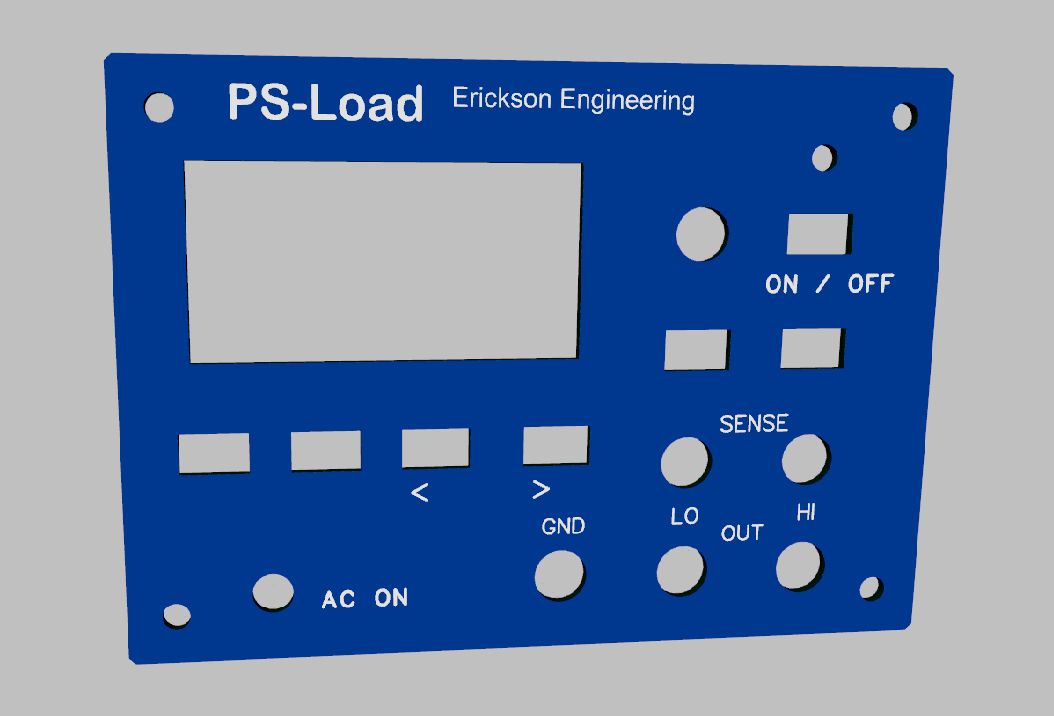

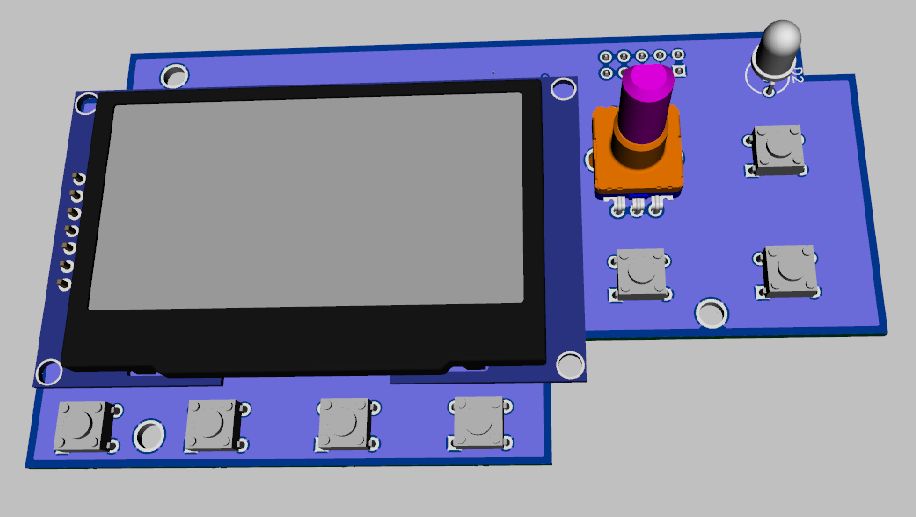

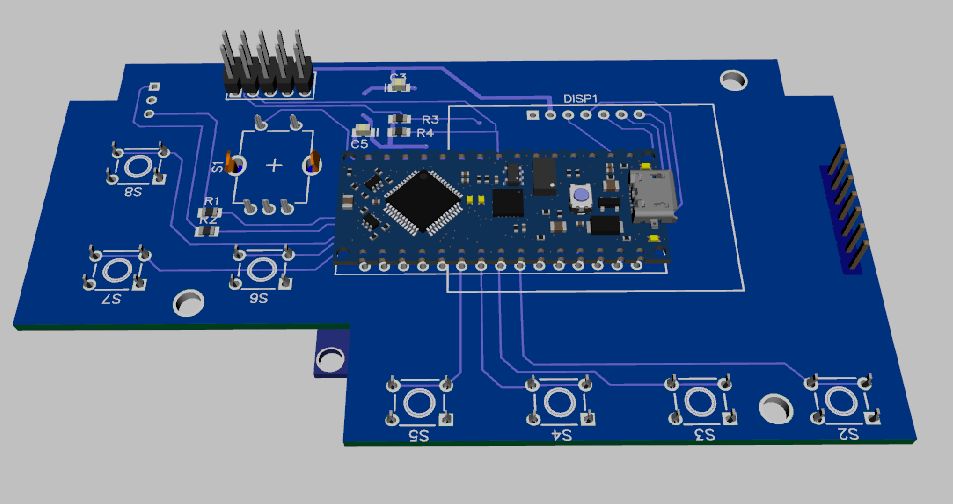

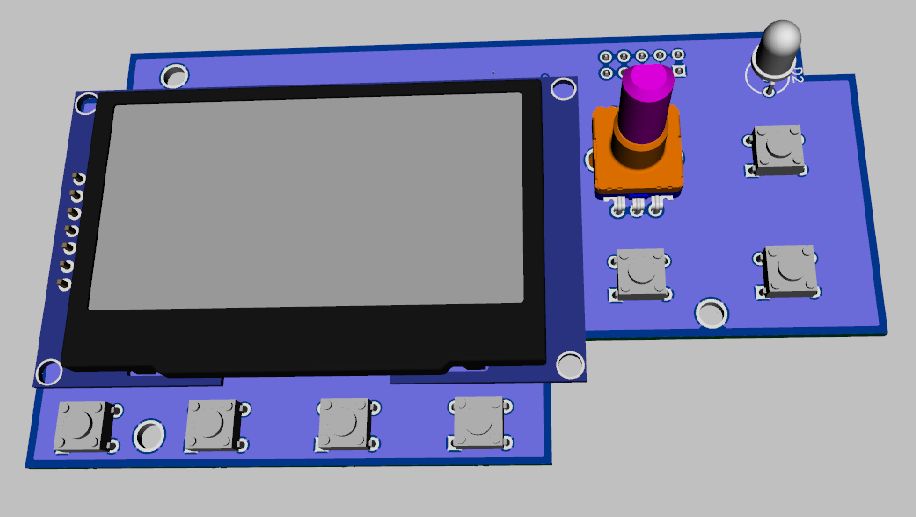

Here is a first pass at

an enclosure and front panel for a single channel PS-Load MkII.

- 24V 4A using 100W

MeanWell supply

- 2U (3.5") x 4.75" x

11.2" enclosure using Gobilda rails

- New front panel

board with 2.42" OLED display and Arduino Nano Every

- Heat sink, AC In,

bottom plate, are not shown

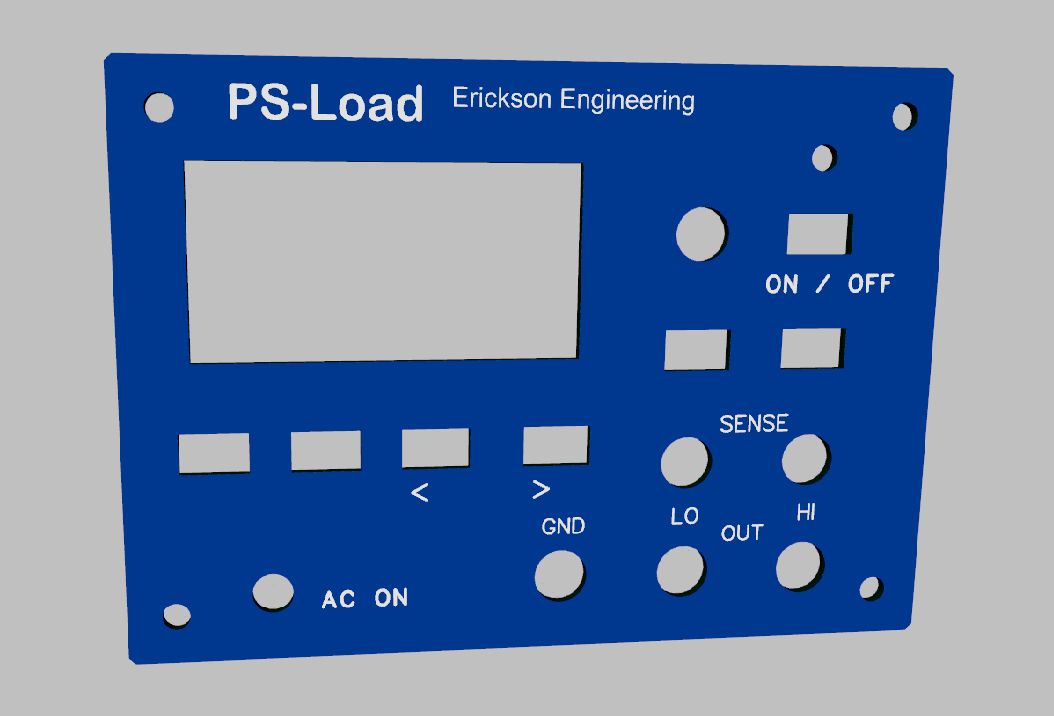

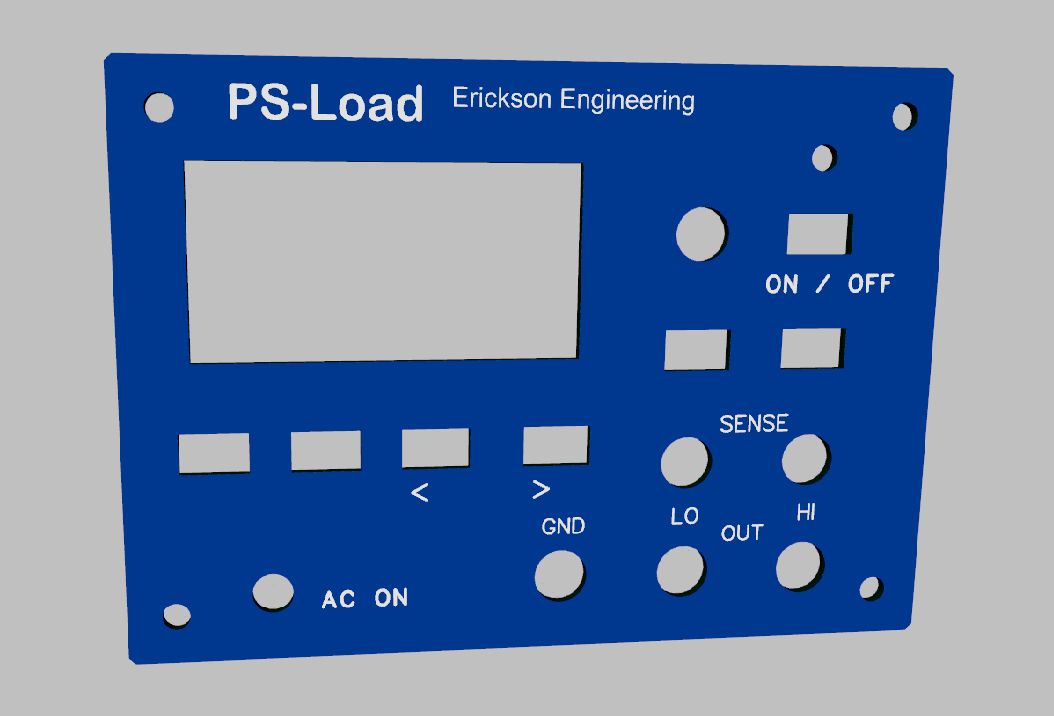

A first pass

front panel. Haven't decided what all the buttons do. Since this

is not a touch panel, I need the buttons to be flexible. The 4

buttons below the OLED could be soft keys, with labels on the

OLED.

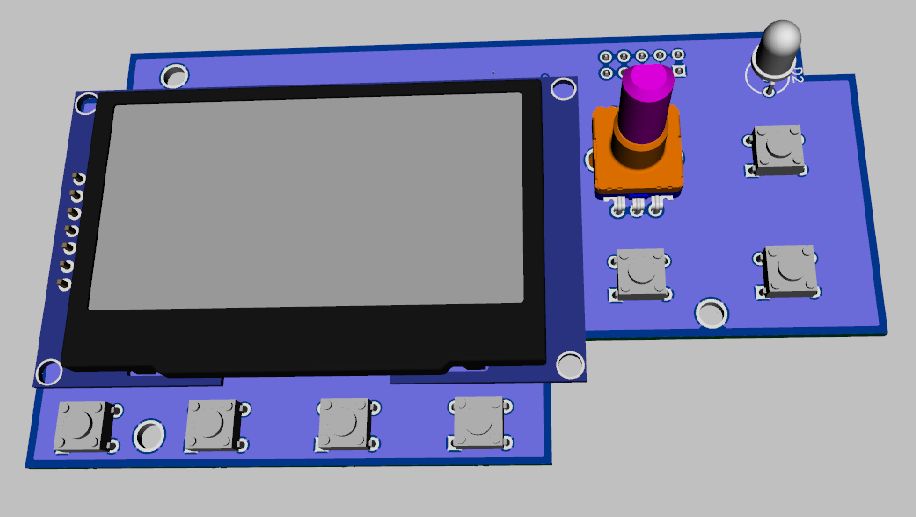

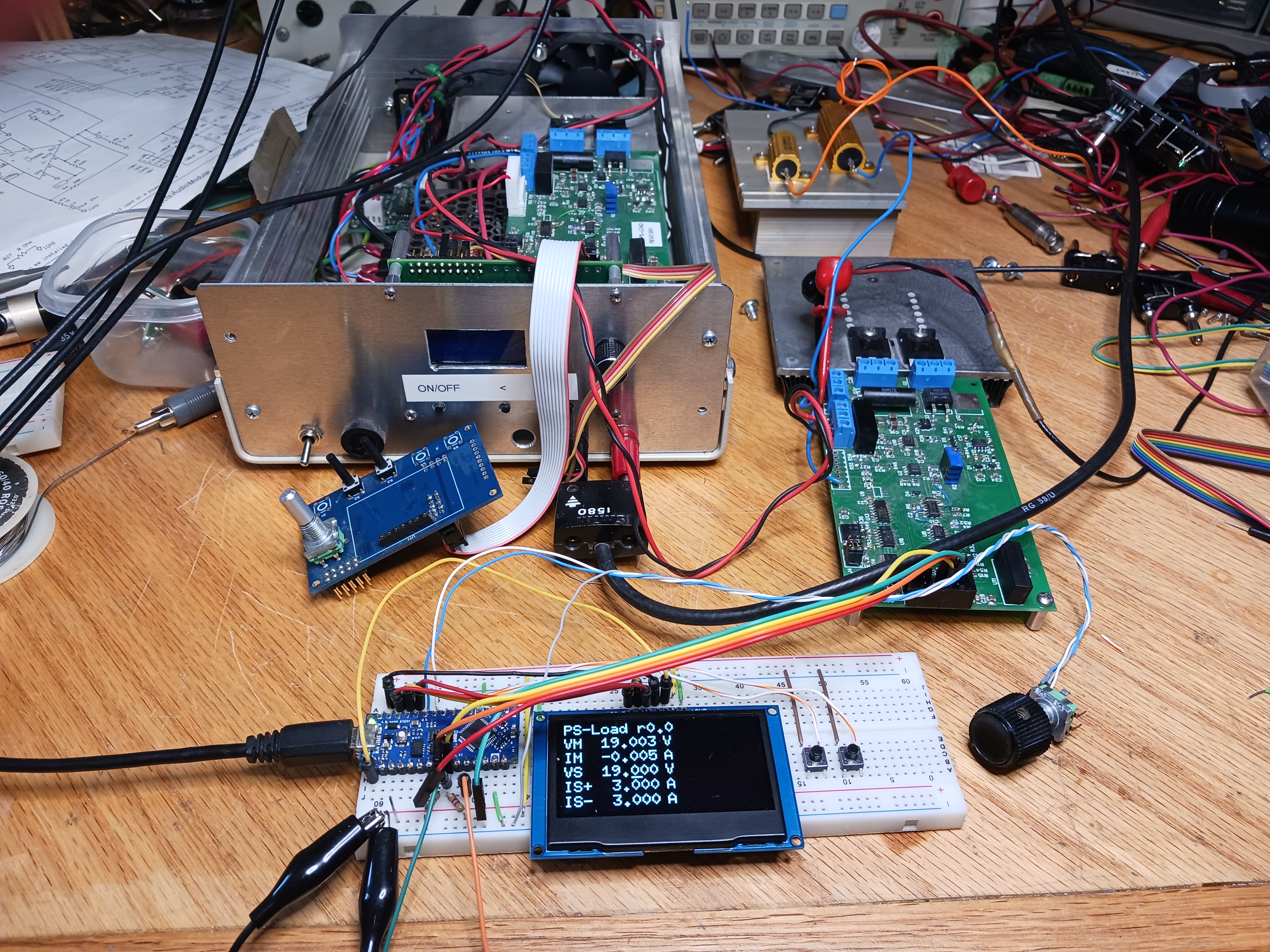

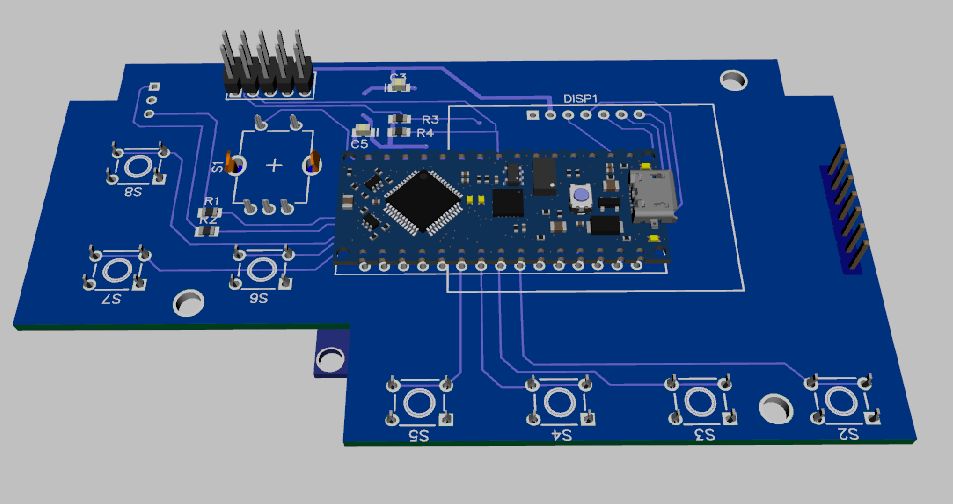

Here is the proposed CPU board with 2.4" OLED.

And the Nano Every on the back.

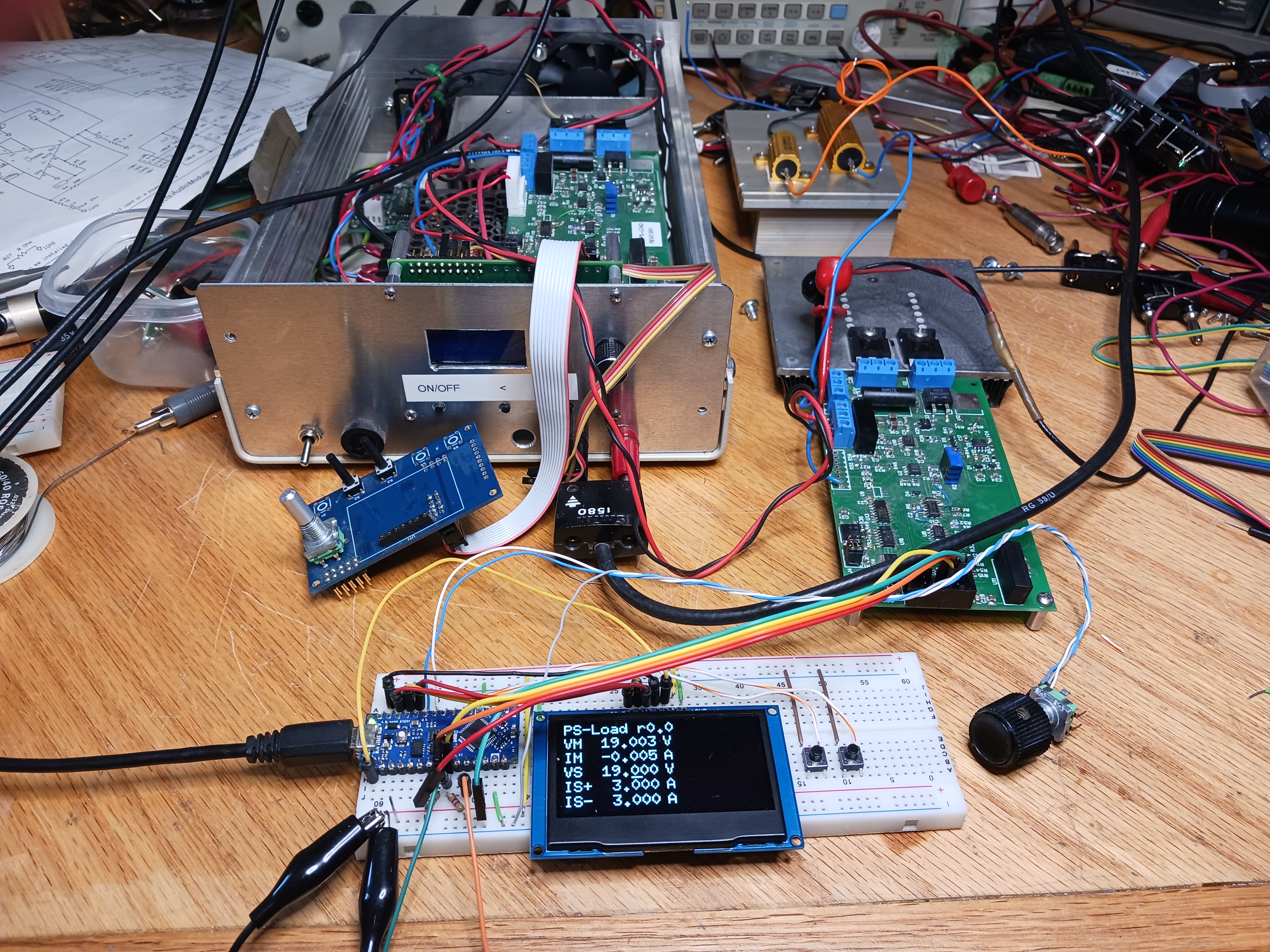

Here is the prototype for PS-Load MKII, next to the original.

Processor is the Nano Every. The basic controls for setting

voltage and measuring voltage and current are working. I'm liking

the big new 2.42" OLED displays. Even the default 5x7 font is

visible from a distance.

Love affair with Nano

Every and Teensy 3.2 has ended :-(

Now that the Covid parts shortage dust has settled, it's time for

a new processor. My new fave low-end processor is the Adafruit

Itsy Bitsy M0. It has lots of I/O, a SAMD21 48MHZ ARM processor,

lots of memory, and a nice 12 bit ADC. And it costs the same $12

as the Nano-Every, whose price has increased. It has

upgrades via the Adafruit Feather product line. I picked the

Itsy-Bitsy because it is smaller and has more I/O than the

Feather, and costs less. It supports MicroPython for you Python

people.

I have one talking to the OLED, and have the 1mS interrupt

working. Next to move it to the PS-Load proto.

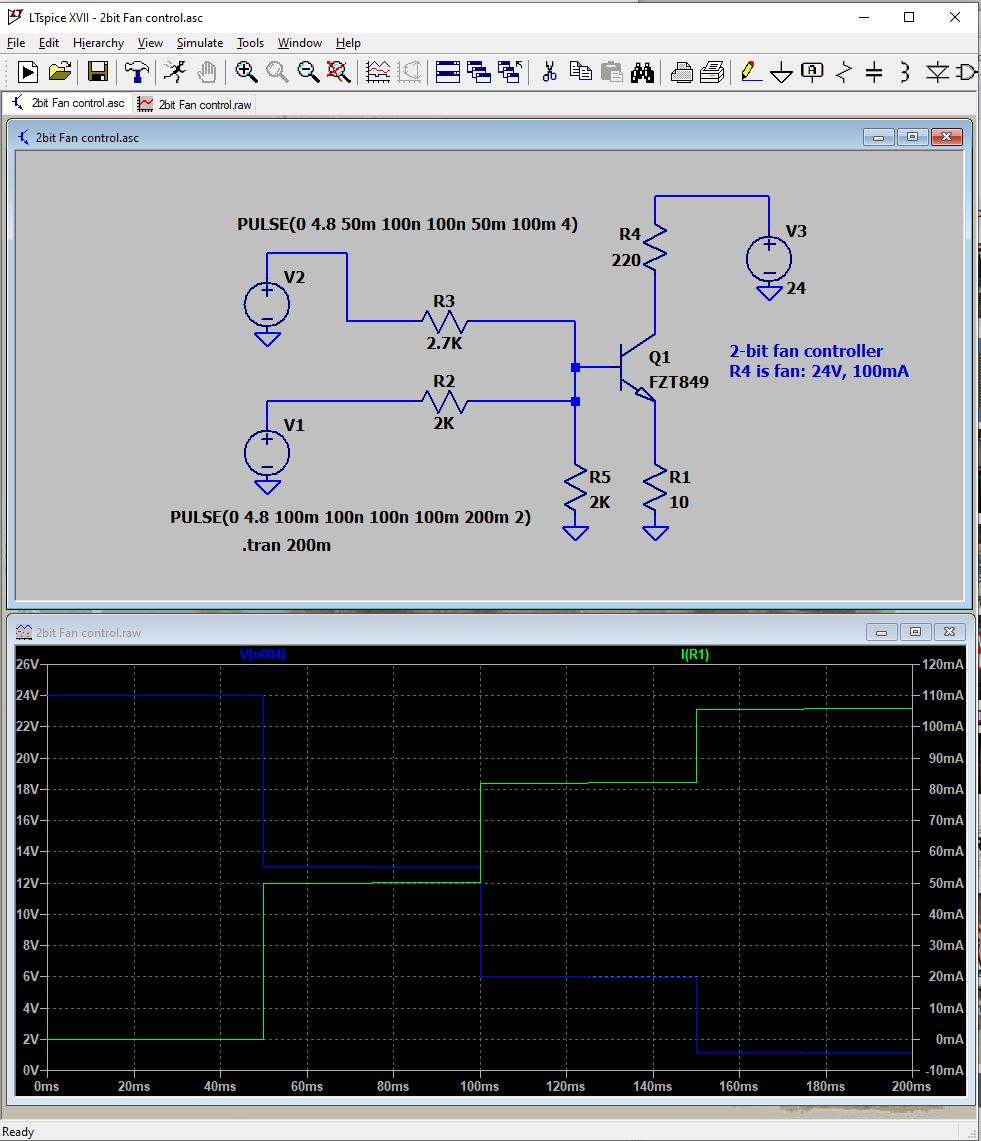

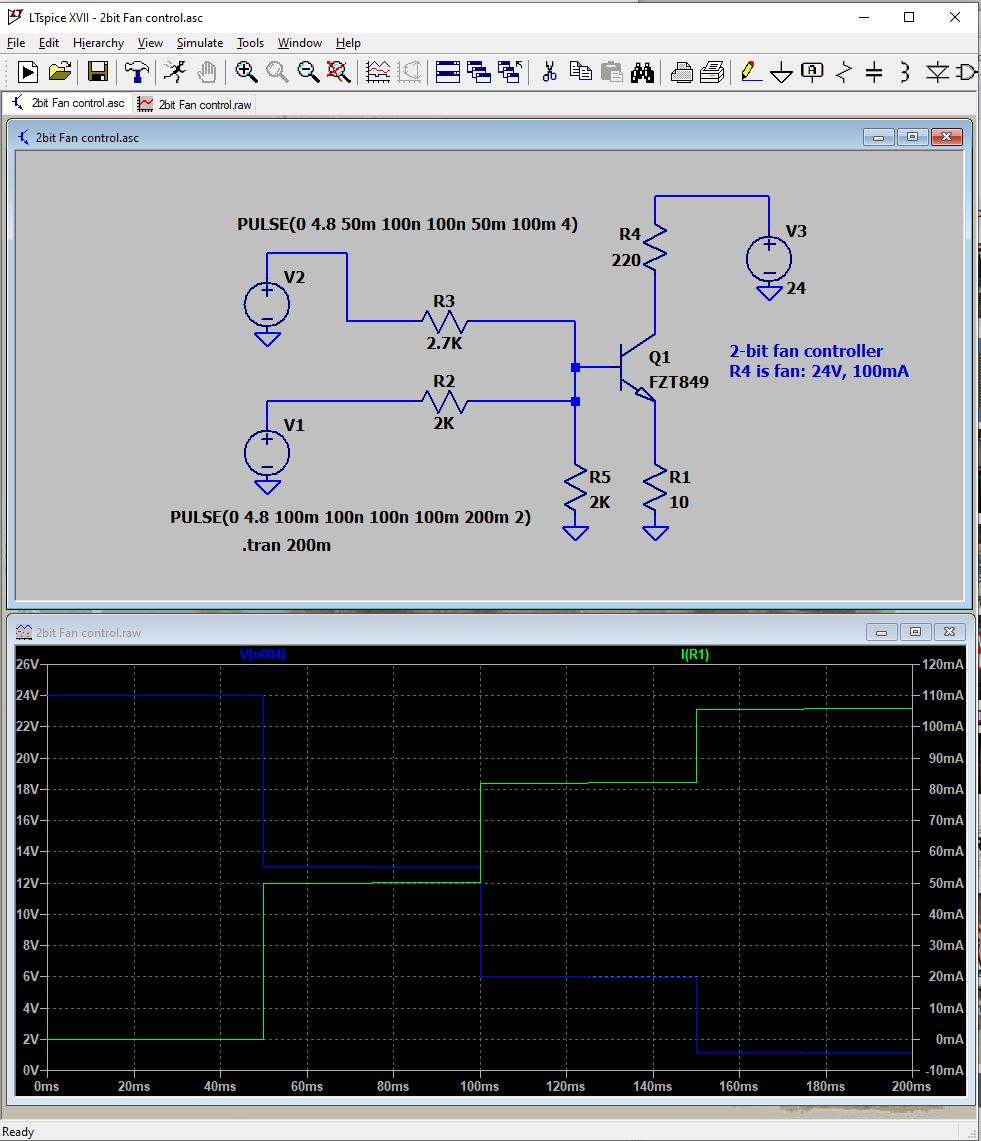

2-bit fan controller

Recognizing that many

projects I do need a fan controller, and my separate fan control

board is a bit over-complicated, here is my latest thinking.

DC brushless fans can be driven by a varying DC voltage or by a

pulsating DC. Pulsating DC can cause acoustic and electrical

noise. I thought I'd try using a simple DC current drive. It supports 3 levels of fan

speed plus off, and uses two isolated 5V control bits, which

PS-Load has plenty of. It uses a simple power transistor as a

crude voltage-to-current controller. I simulated and tested it and

it works well. It will work with most fans up to a few watts: 12,

24 or 48V. Just change the 10 ohm resistor to increase or decrease

the fan current. The transistor can be any NPN power device

capable of dissipating about 1W: TO-220, SOT-223 or D-PAK.

The output across the fan should be filtered by about a 22-100uF

cap since fan motors draw pulsating currents. Since it is

controlled by the CPU, it can be operated in a closed loop by the

CPU monitoring the heat-sink temperature, or open loop, by

estimating temperature rise based on dissipated power. In

the case of PS-Load, the firmware knows the output V, Power supply

V, and output current, so it can calculate the FETs power

dissipation. This, plus the heat sink thermal resistance can be

used to estimate temp. rise of the FETs. Then adjust the fan speed

accordingly. Ideally you would also know

the ambient temperature, but since this is a laboratory

instrument, a small range of ambient temperatures can be

assumed. Not true if you need to operate from a wide range of

temperatures. Saves a temperature sensor and its wiring

and mounting.

The

Blog for this project

The

DIY-SMU project

Dave's Home Page

Last Updated:

7/25/2024